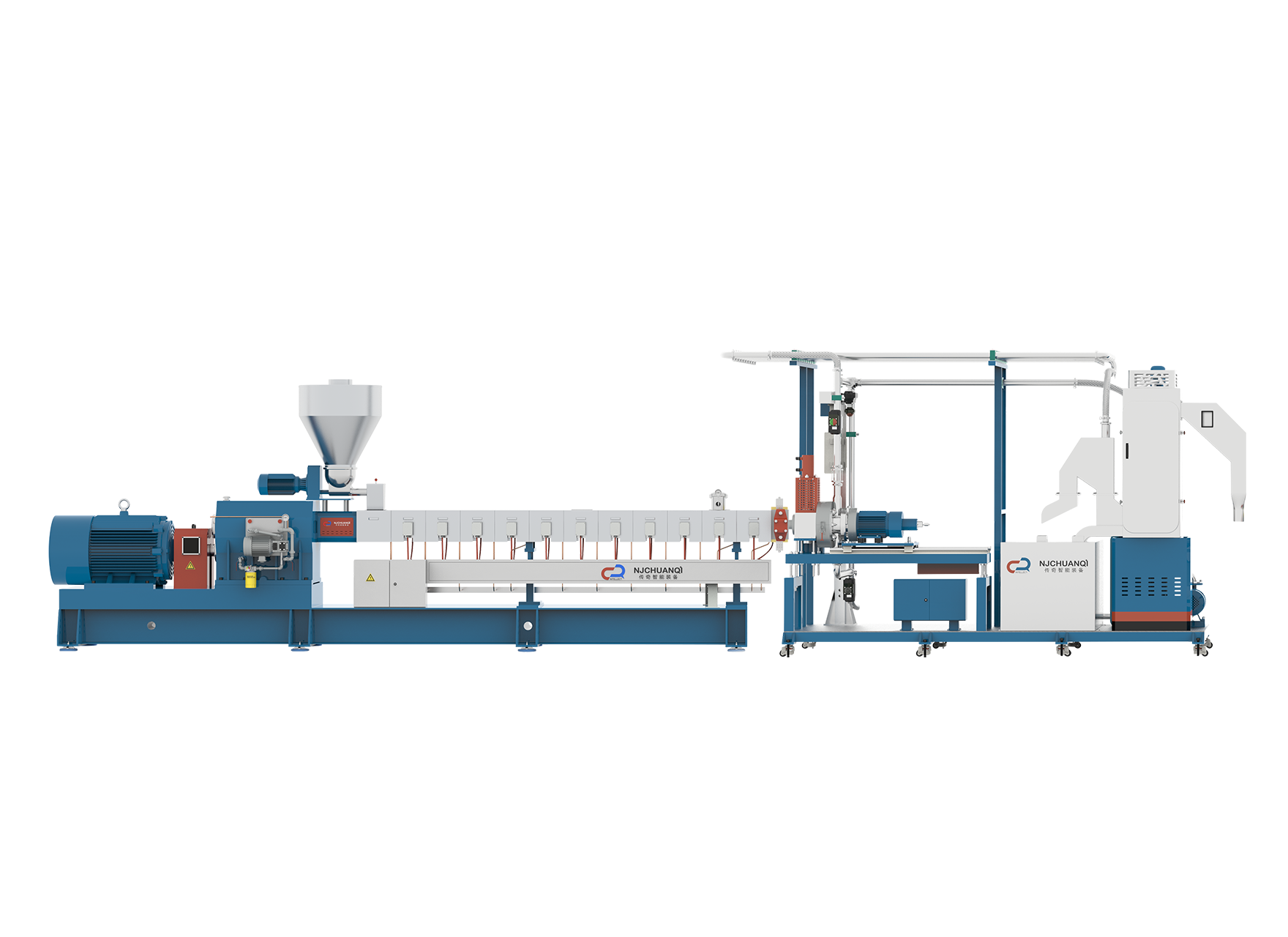

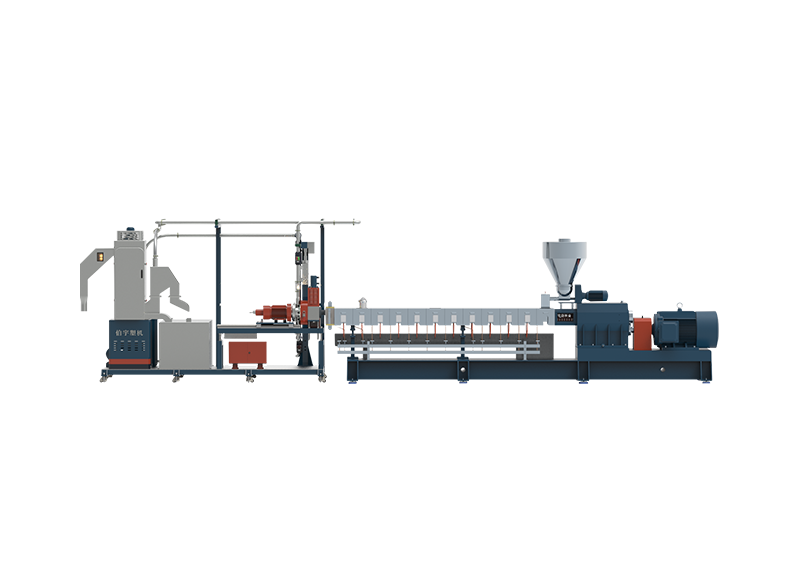

Sale OEM PE Plastic Extrusion Equipment Machine Producer

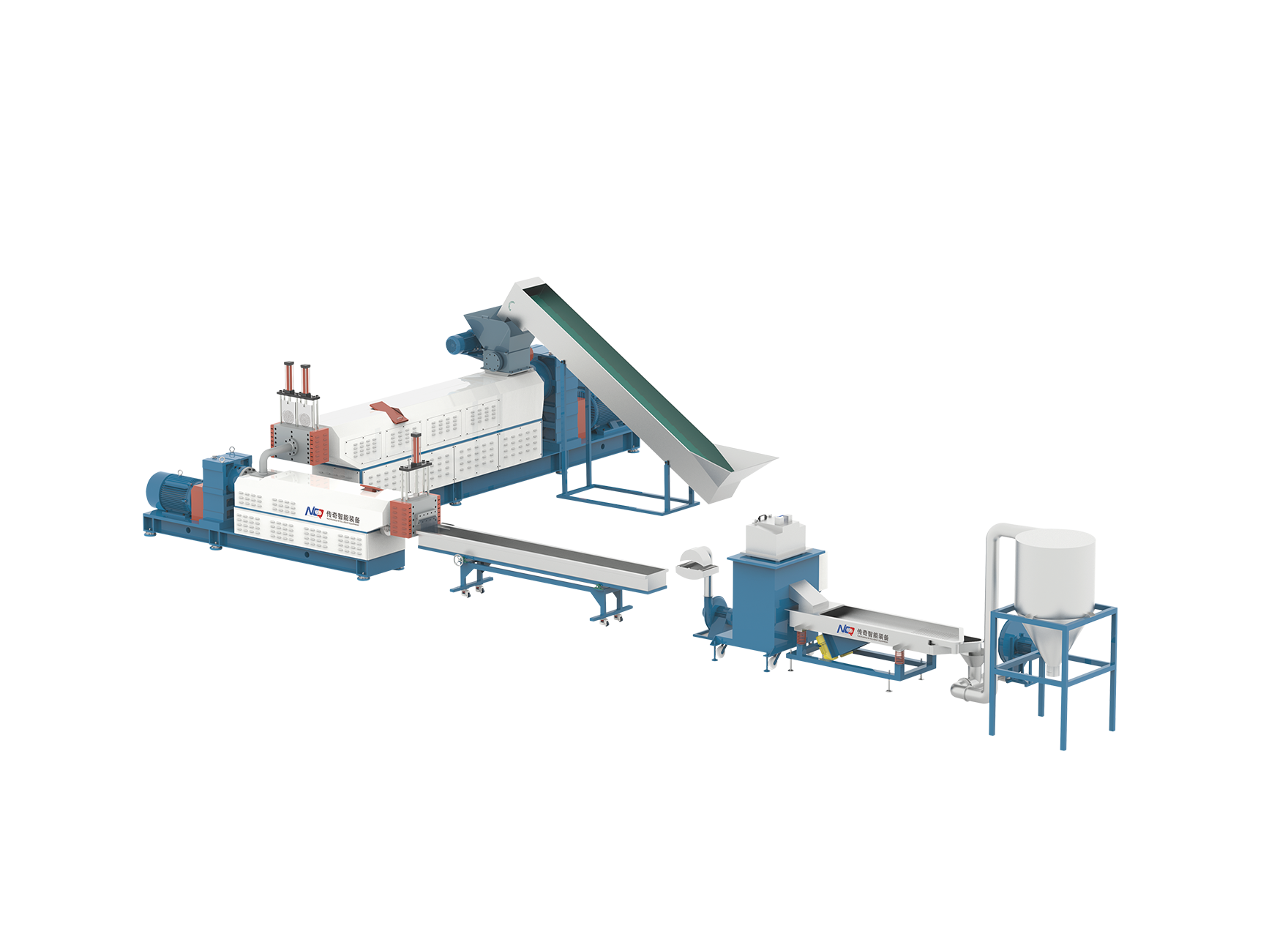

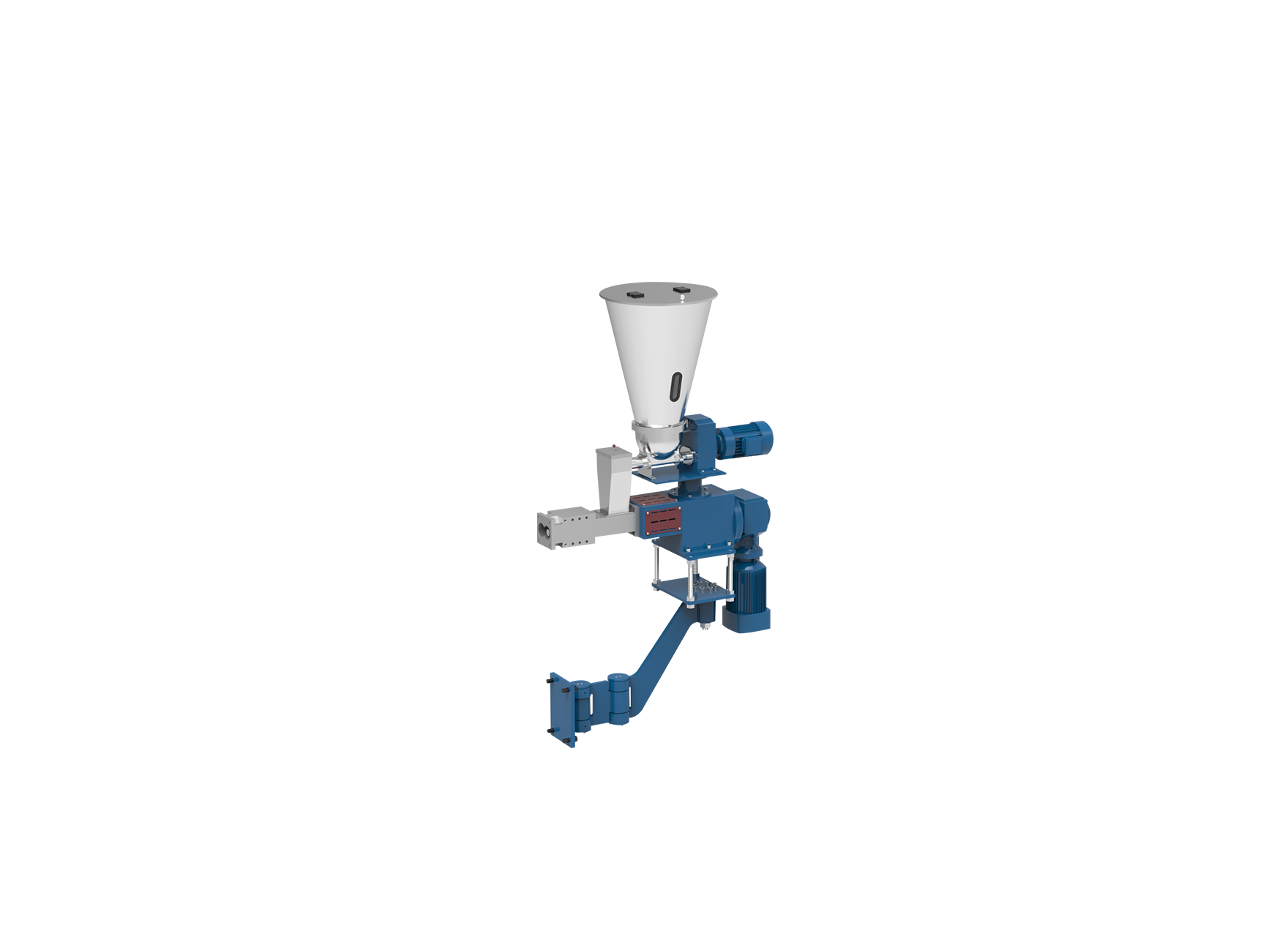

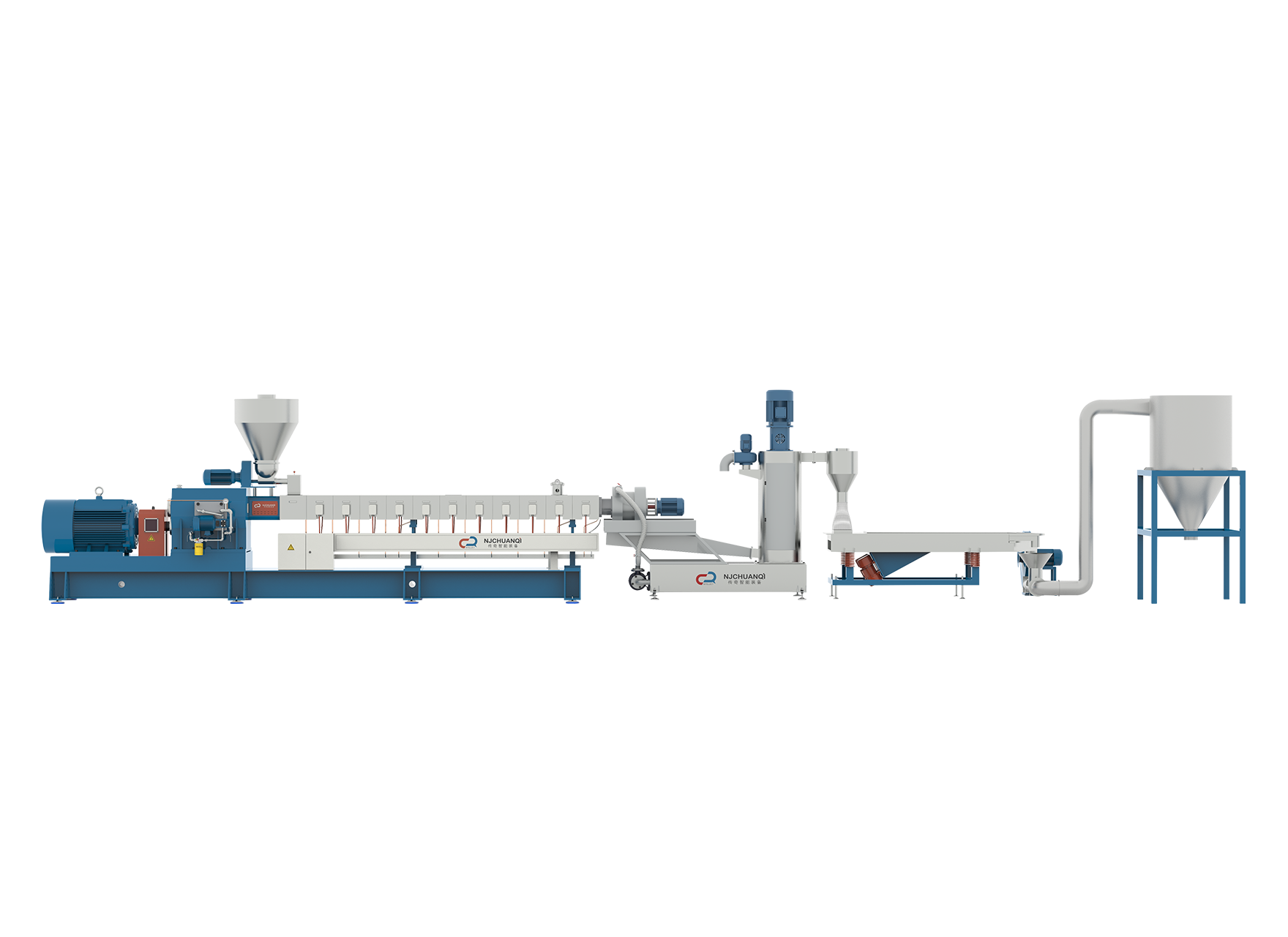

In the realm of polymer processing, the efficiency of Plastic Extrusion Equipment and Laboratory Twin Screw Extruder is paramount to the success of manufacturing operations. These machines are not merely tools; they are the backbone of the production process, capable of shaping the future of plastics manufacturing. To harness their full potential and increase work efficiency, several strategies can be implemented, which will be explored in this article.

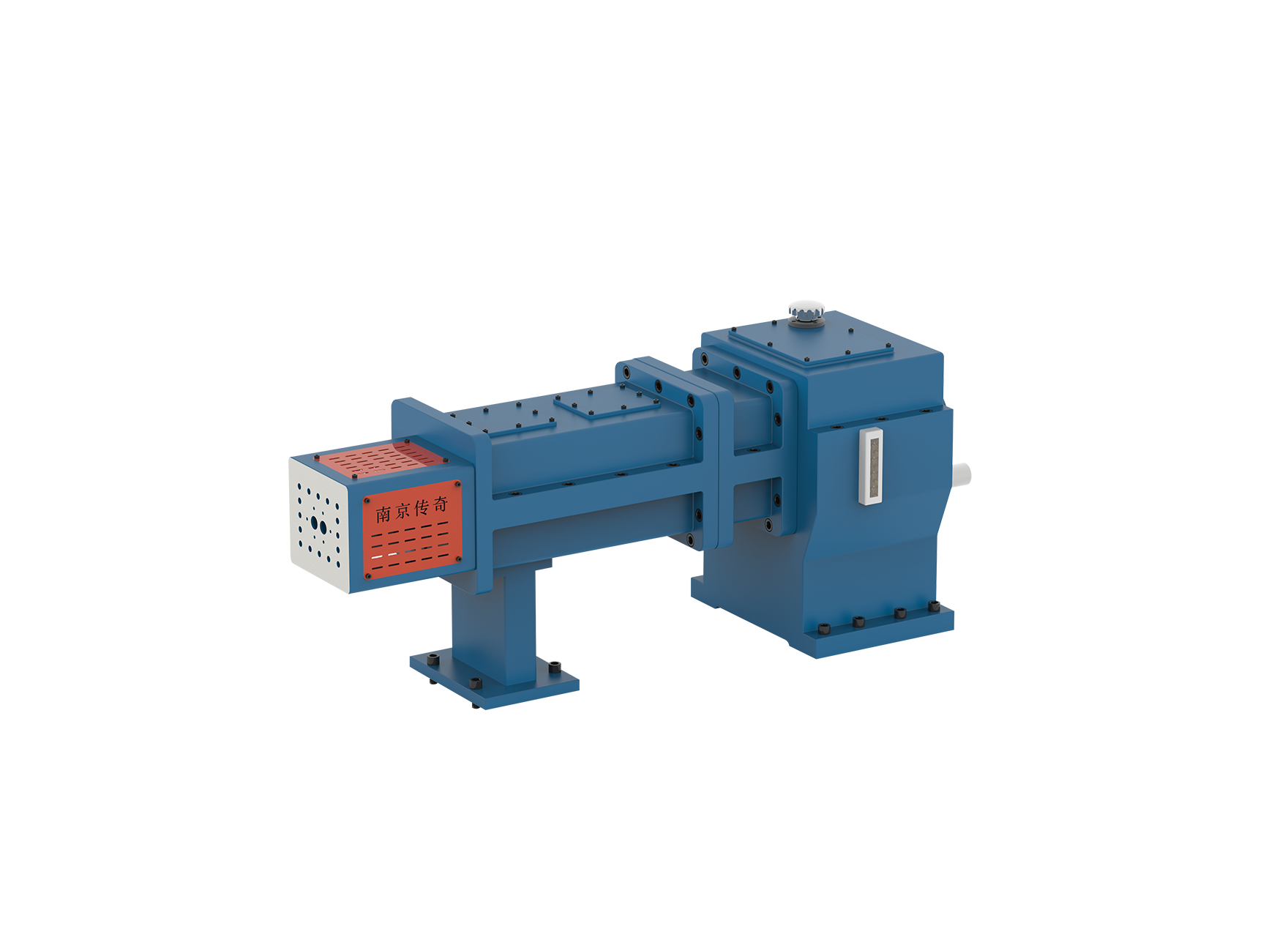

Understanding the specific requirements of the material being processed is crucial. The Plastic Extrusion Equipment and Laboratory Twin Screw Extruder must be tailored to the rheological properties of the polymer. By fine-tuning the processing parameters such as temperature, pressure, and screw speed, one can achieve a more consistent and efficient extrusion process. This customization ensures that the equipment is not overworked or underperforming, thus improving its output.

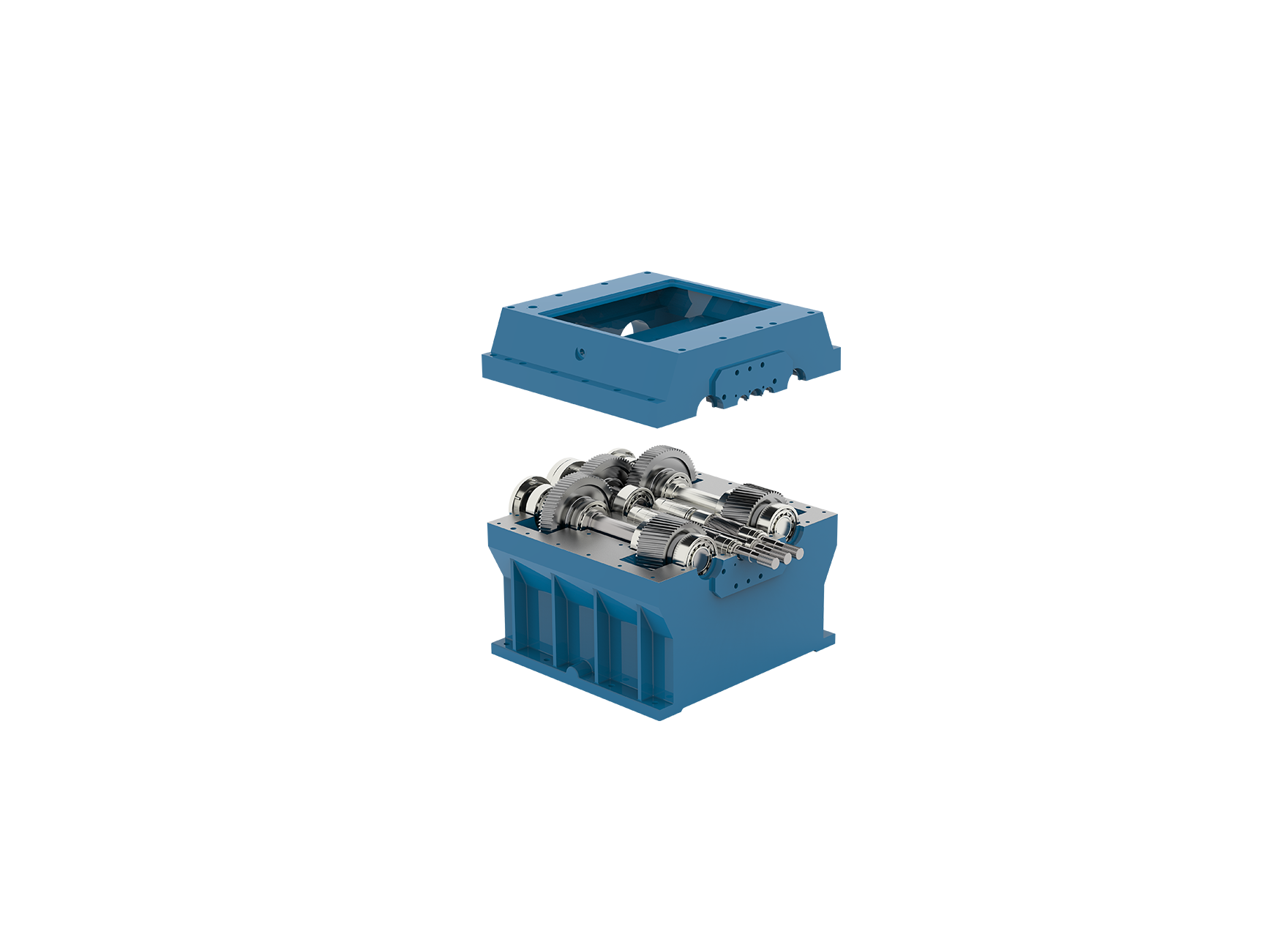

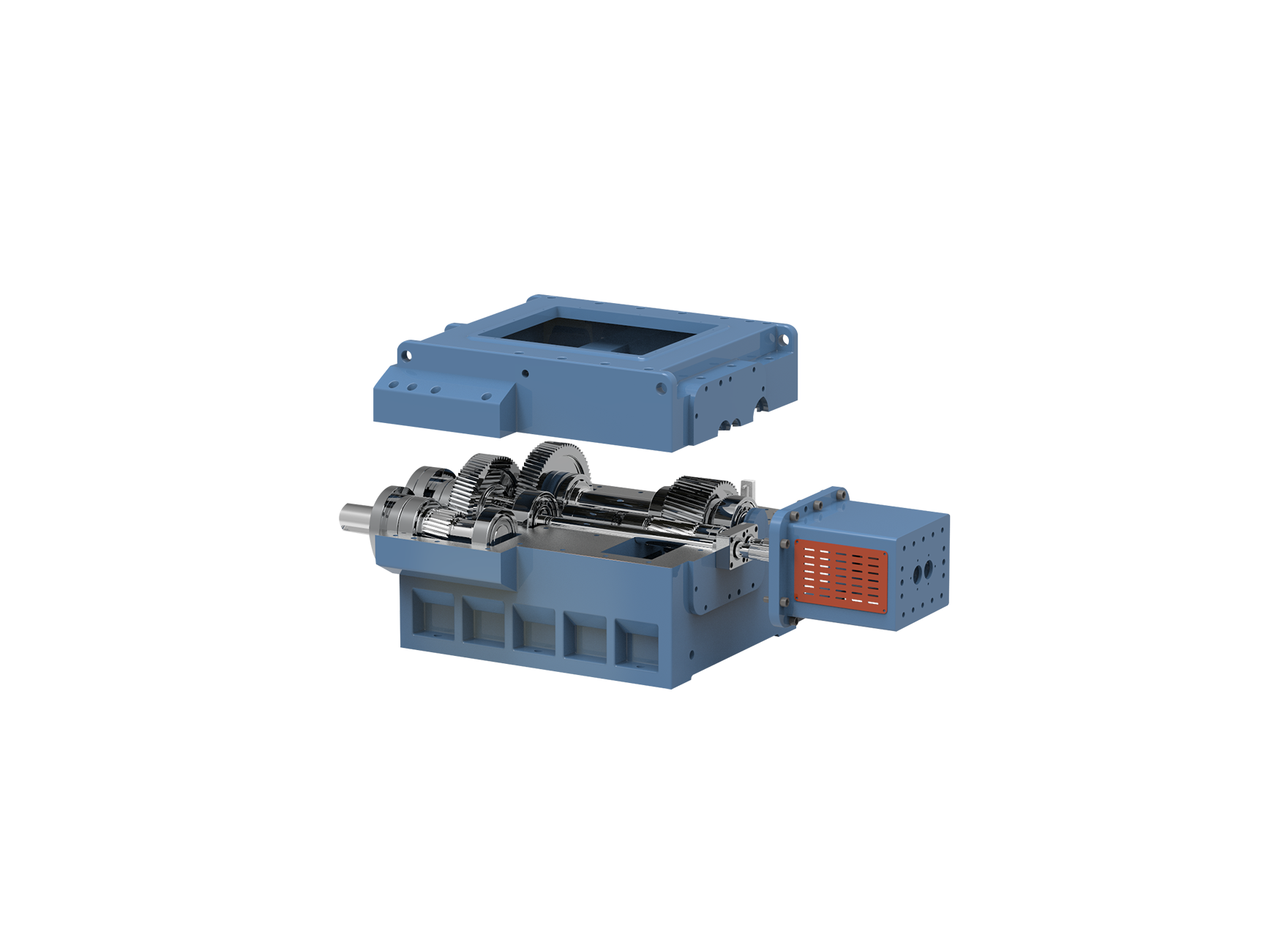

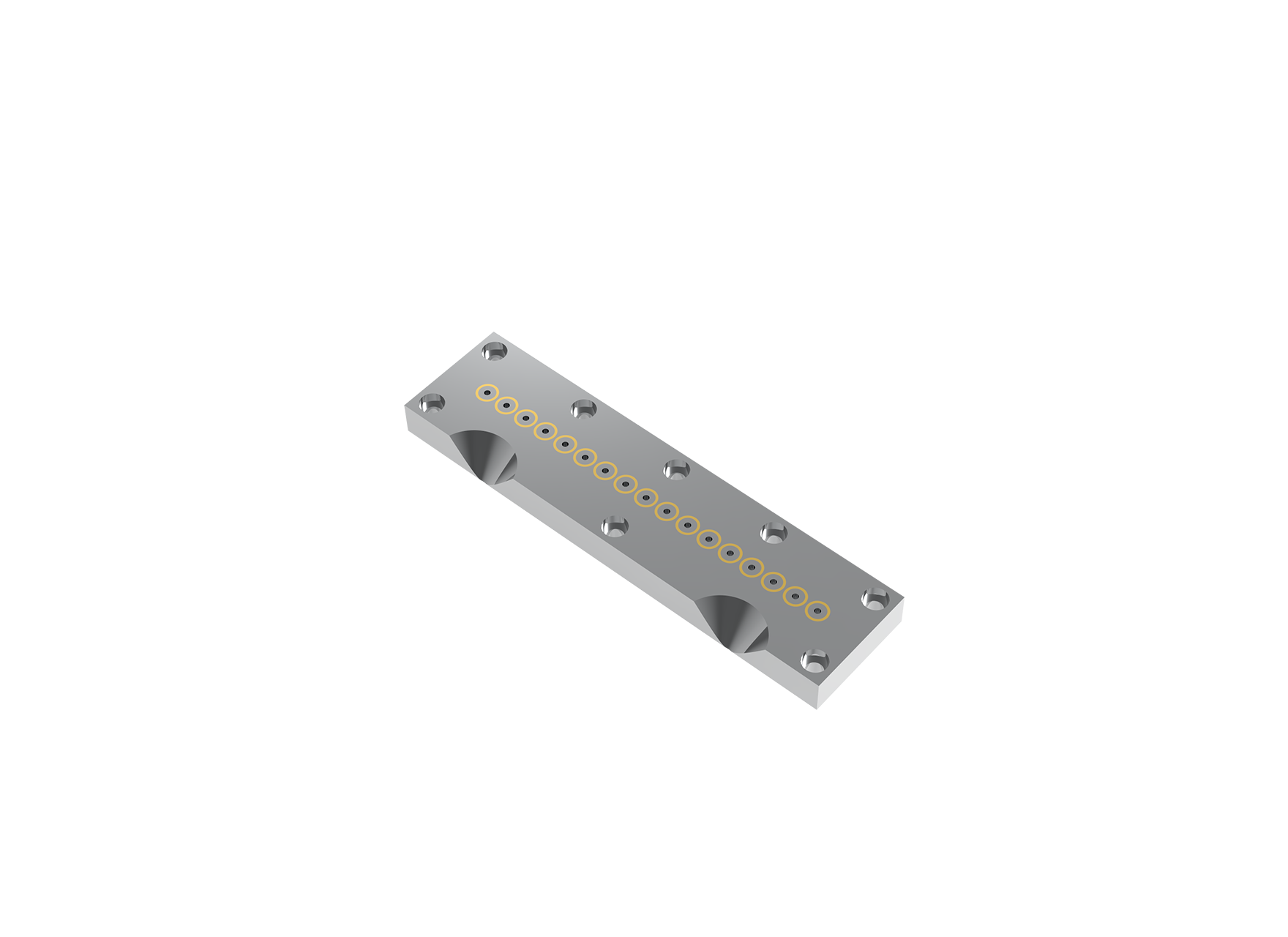

Secondly, regular maintenance and upkeep of the Plastic Extrusion Equipment and Laboratory Twin Screw Extruder are non-negotiable. A well-maintained machine operates more smoothly and with fewer interruptions. Preventative maintenance, such as checking for wear and tear, lubricating moving parts, and ensuring that all components are clean, can significantly reduce downtime and improve the overall efficiency of the equipment.

Moreover, the utilization of advanced control systems can greatly enhance the productivity of Plastic Extrusion Equipment and Laboratory Twin Screw Extruder. Modern systems offer precise control over the extrusion process, allowing for real-time adjustments and data analysis. These systems can help in identifying inefficiencies and making necessary corrections on the fly, causing a more streamlined and efficient operation.

Training the workforce to operate the Plastic Extrusion Equipment and Laboratory Twin Screw Extruder effectively is another critical aspect of increasing efficiency. A skilled operator can make decisions that optimize the performance of the equipment, such as adjusting the extrusion profile to decrease waste or identifying when to switch to a new batch of material. Investing in training and development programs can cause a more knowledgeable and responsive team, which in turn can improve the efficiency of the entire production line.

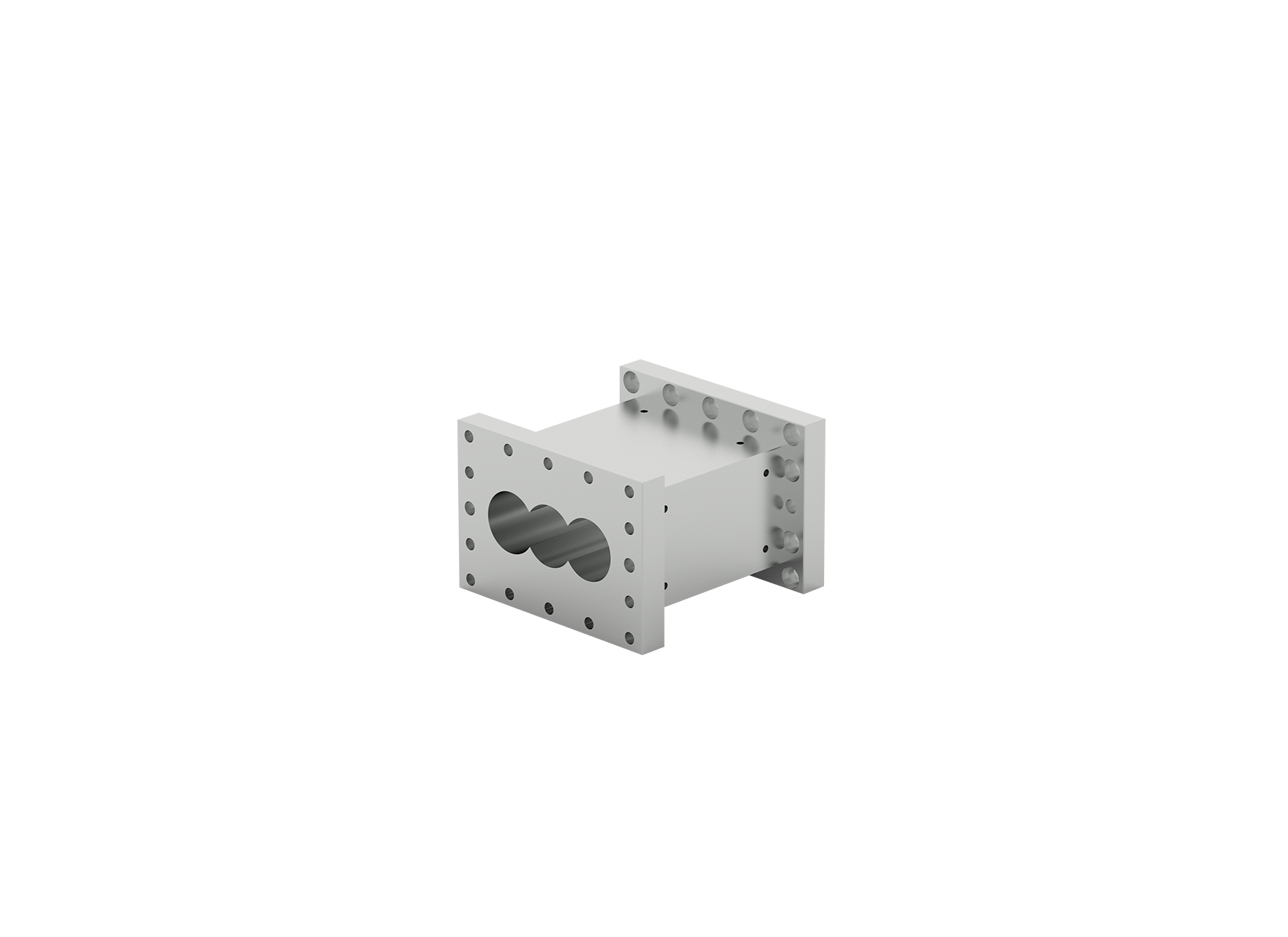

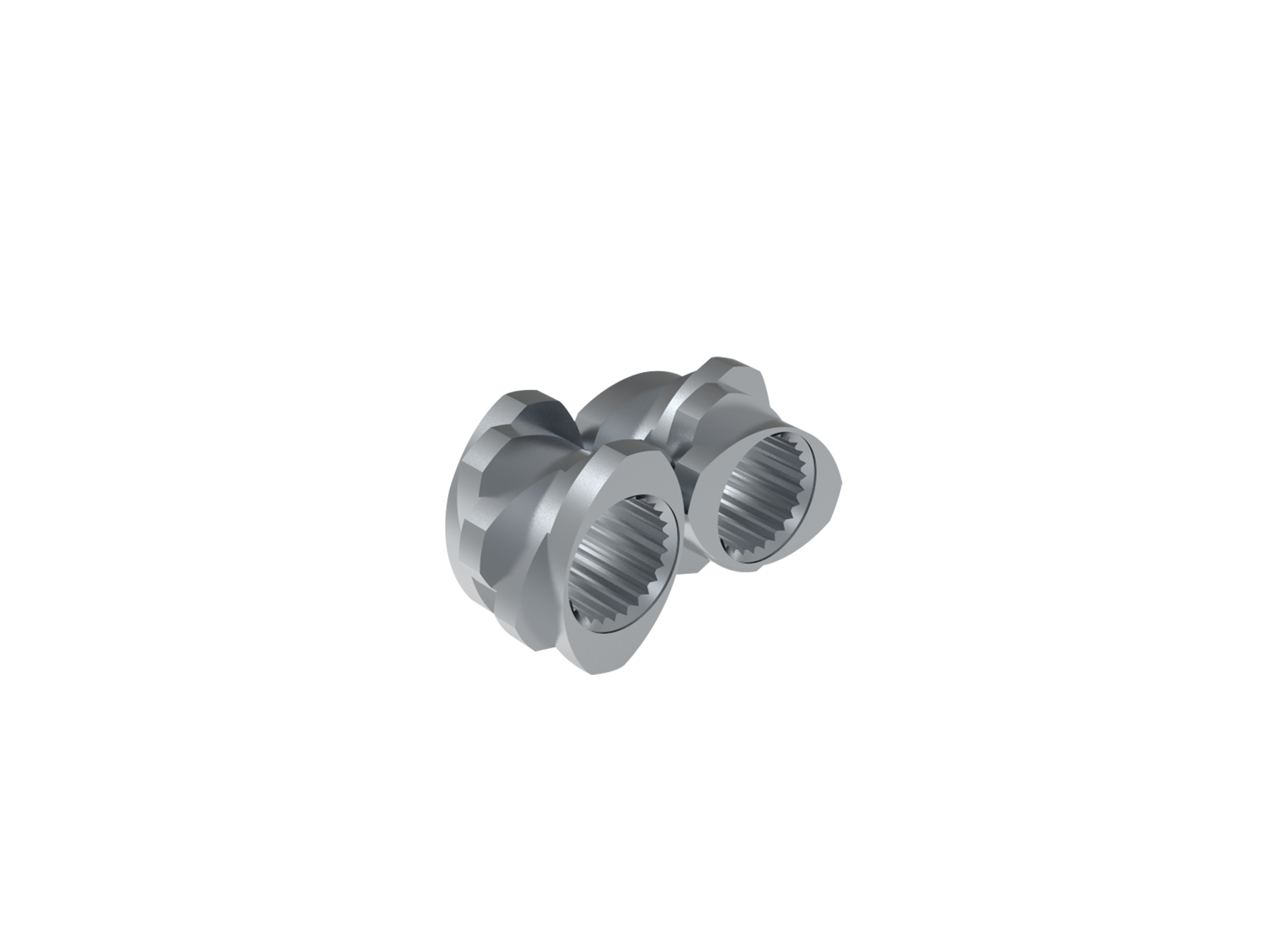

In addition to these operational strategies, the design of the Plastic Extrusion Equipment and Laboratory Twin Screw Extruder itself can be a factor in productivity. Newer models often come with features that reduce the time it takes to switch between different types of polymers or products. This flexibility can be a significant advantage in a market that demands a diverse range of products with quick turnaround times.

Collaboration between research and development teams and the operations team is also essential. The Laboratory Twin Screw Extruder, being a more controlled environment, can provide valuable insights into the behavior of materials under various conditions. These insights can then be applied to the larger-scale Plastic Extrusion Equipment, causing process improvements that increase efficiency and reduce costs.

Finally, embracing Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), can change the way Plastic Extrusion Equipment and Laboratory Twin Screw Extruder are operated. These technologies enable the collection and analysis of vast amounts of data, which can be used to predict machine performance, identify trends, and make proactive adjustments to the production process.

In conclusion, enhancing the efficiency of Plastic Extrusion Equipment and Laboratory Twin Screw Extruder is a multifaceted endeavor that requires a combination of well-maintained machinery, skilled operators, advanced control systems, and the integration of technologies. By focusing on these areas, manufacturers can ensure that their extrusion processes are not only efficient but also poised to meet the challenges of the future.

English

English 中文简体

中文简体 русский

русский عربى

عربى +86-189 1339 2785

+86-189 1339 2785