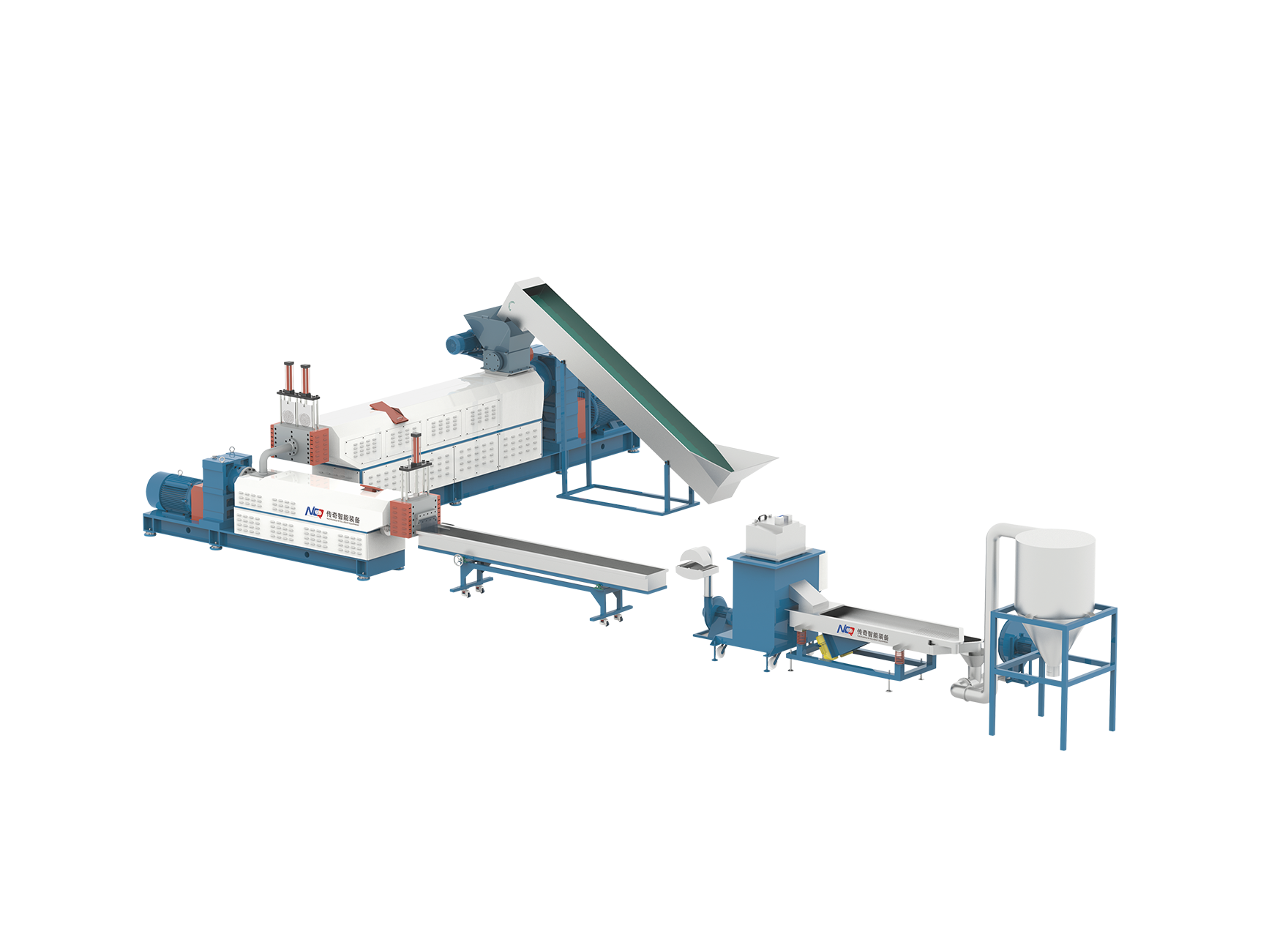

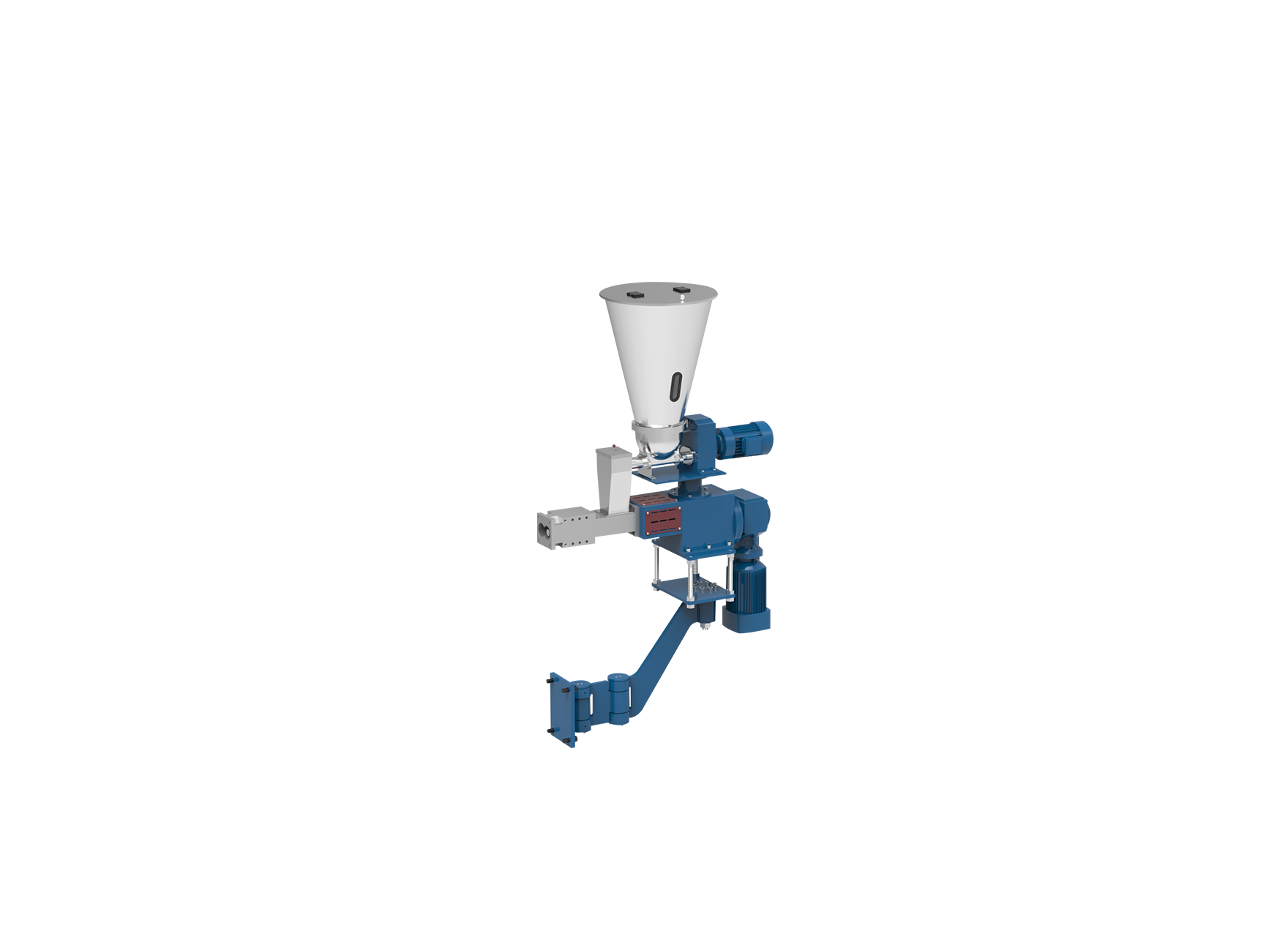

In industries such as fertilizers, chemicals, and pharmaceuticals, the quality of granules plays a critical role in product performance, storage stability, and application efficiency. One key factor influencing granule quality is the method of production, and the Roller Granulator has become a popular choice for dry granulation processes. Among the primary performance metrics in evaluating granule quality are particle strength and uniformity. This article examines how well granules produced by a Roller Granulator meet these criteria and what factors contribute to their consistency and mechanical durability.

Mechanical Compaction and Its Impact on Granule Strength

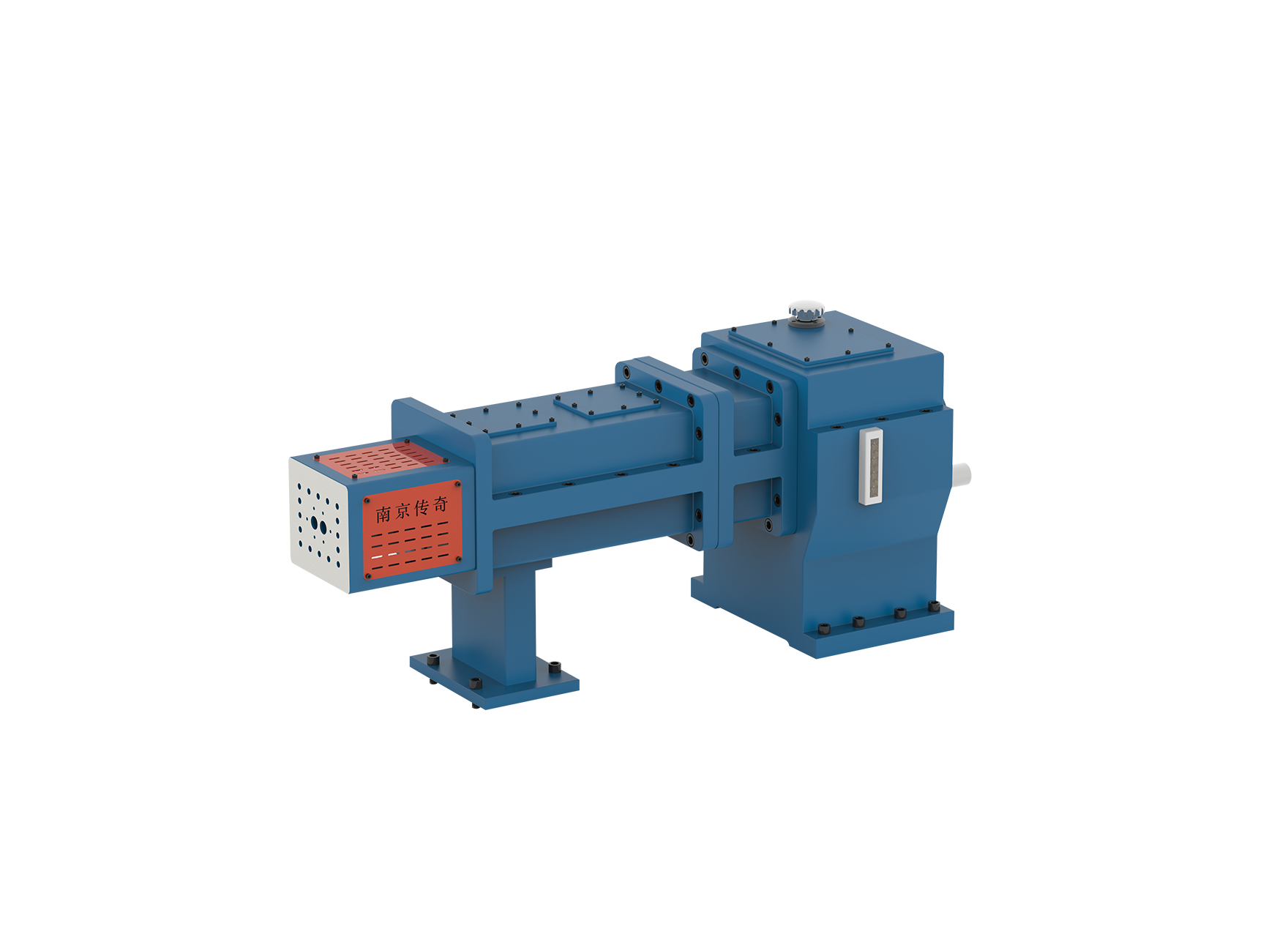

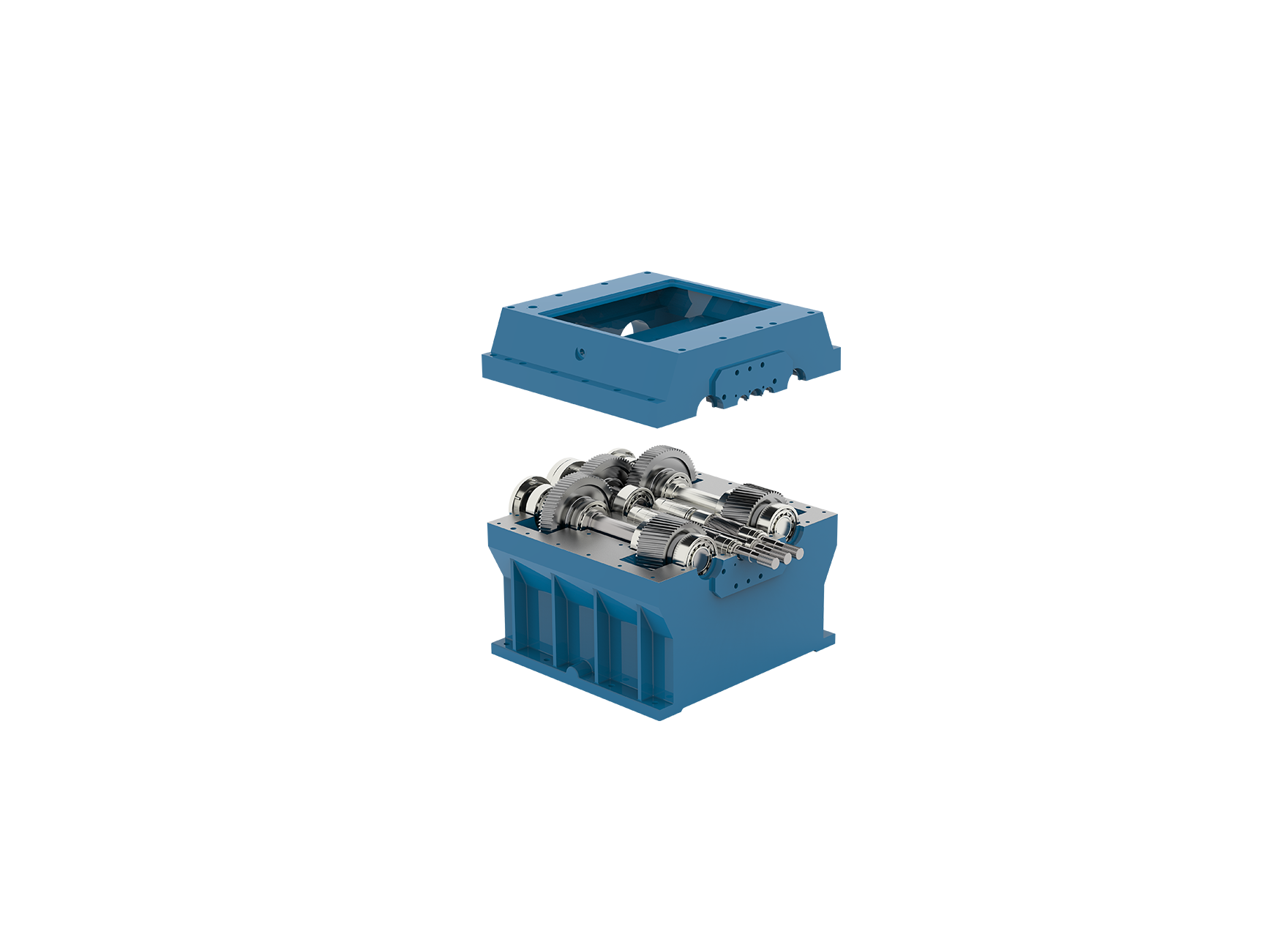

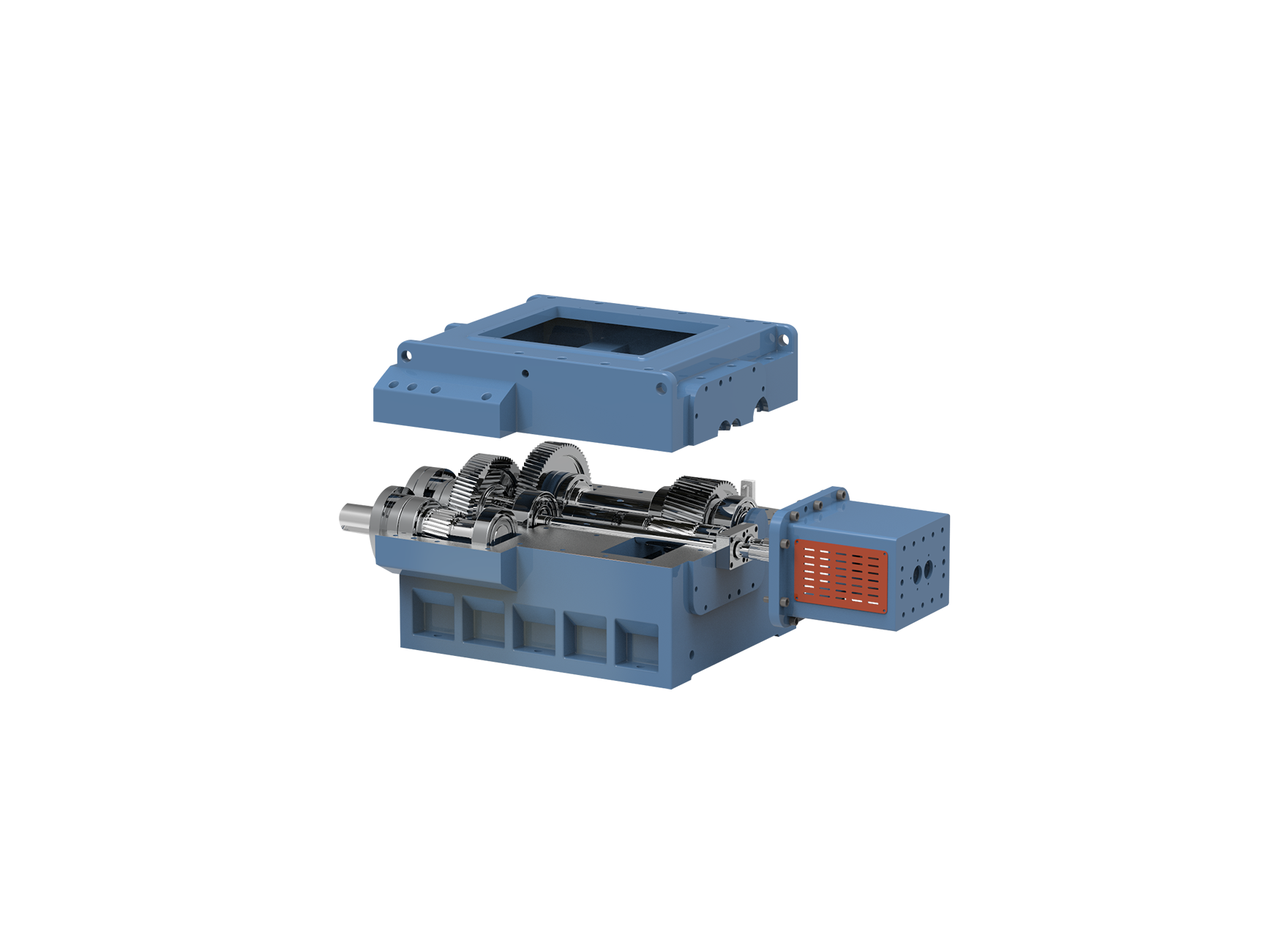

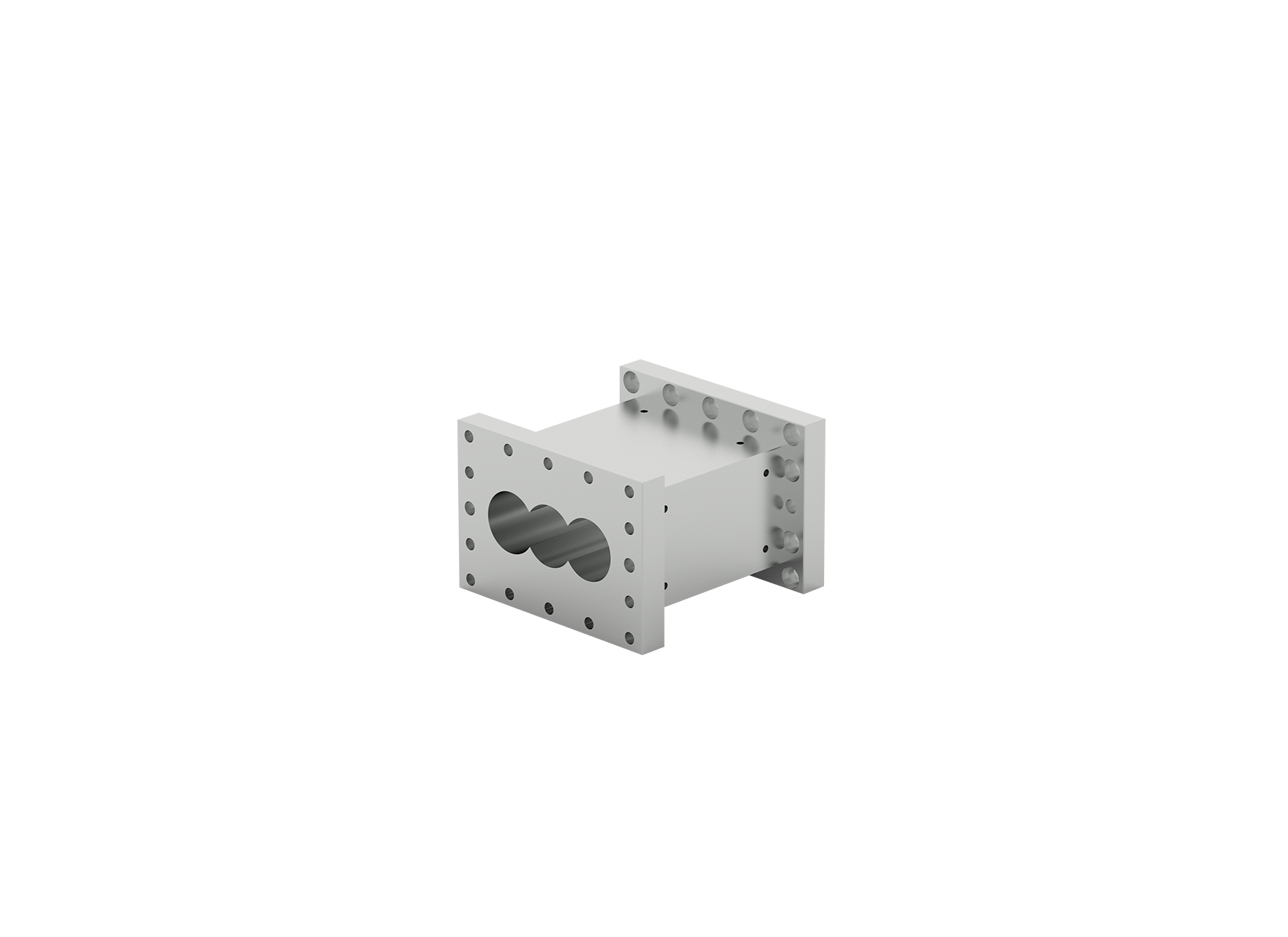

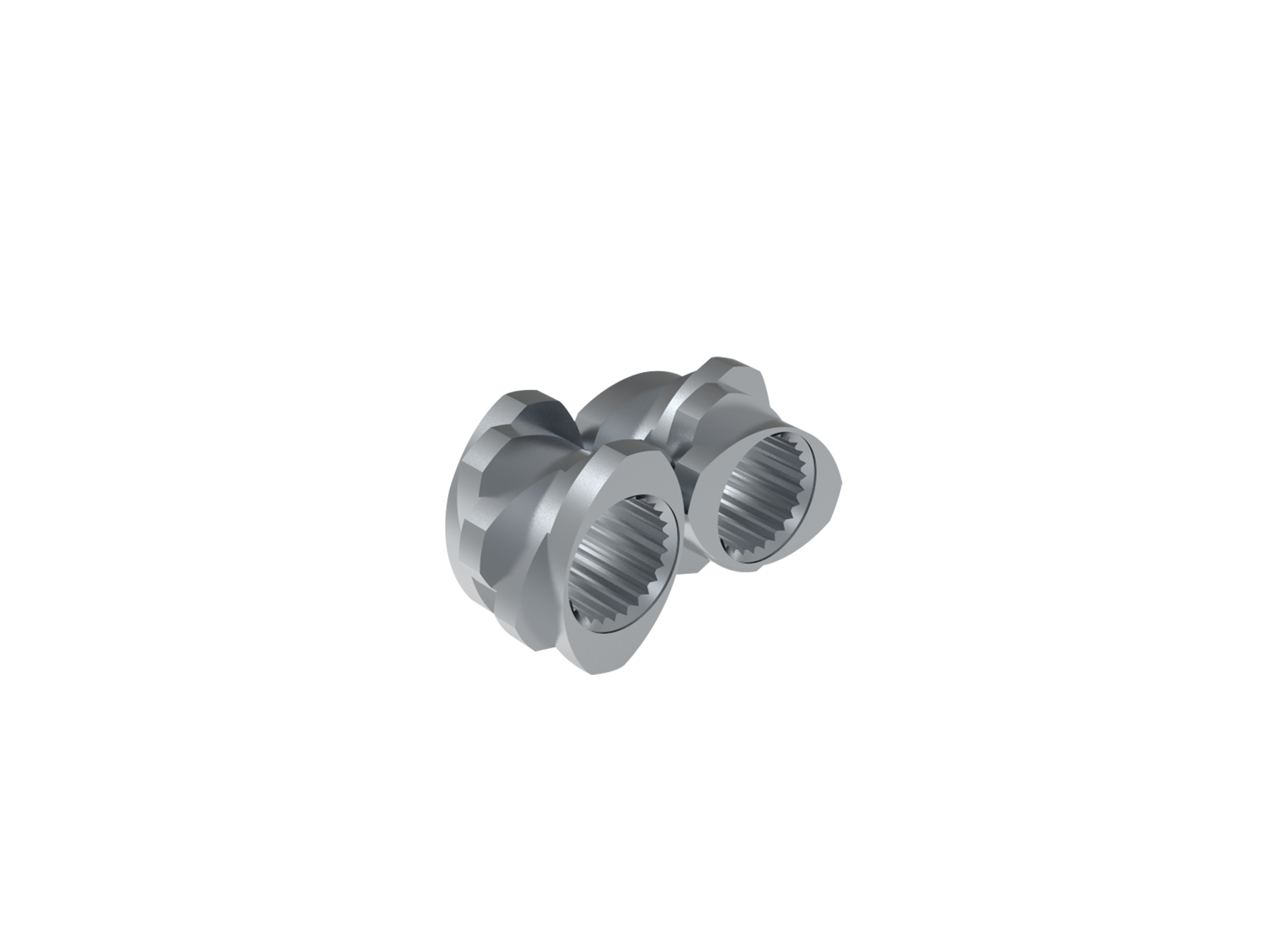

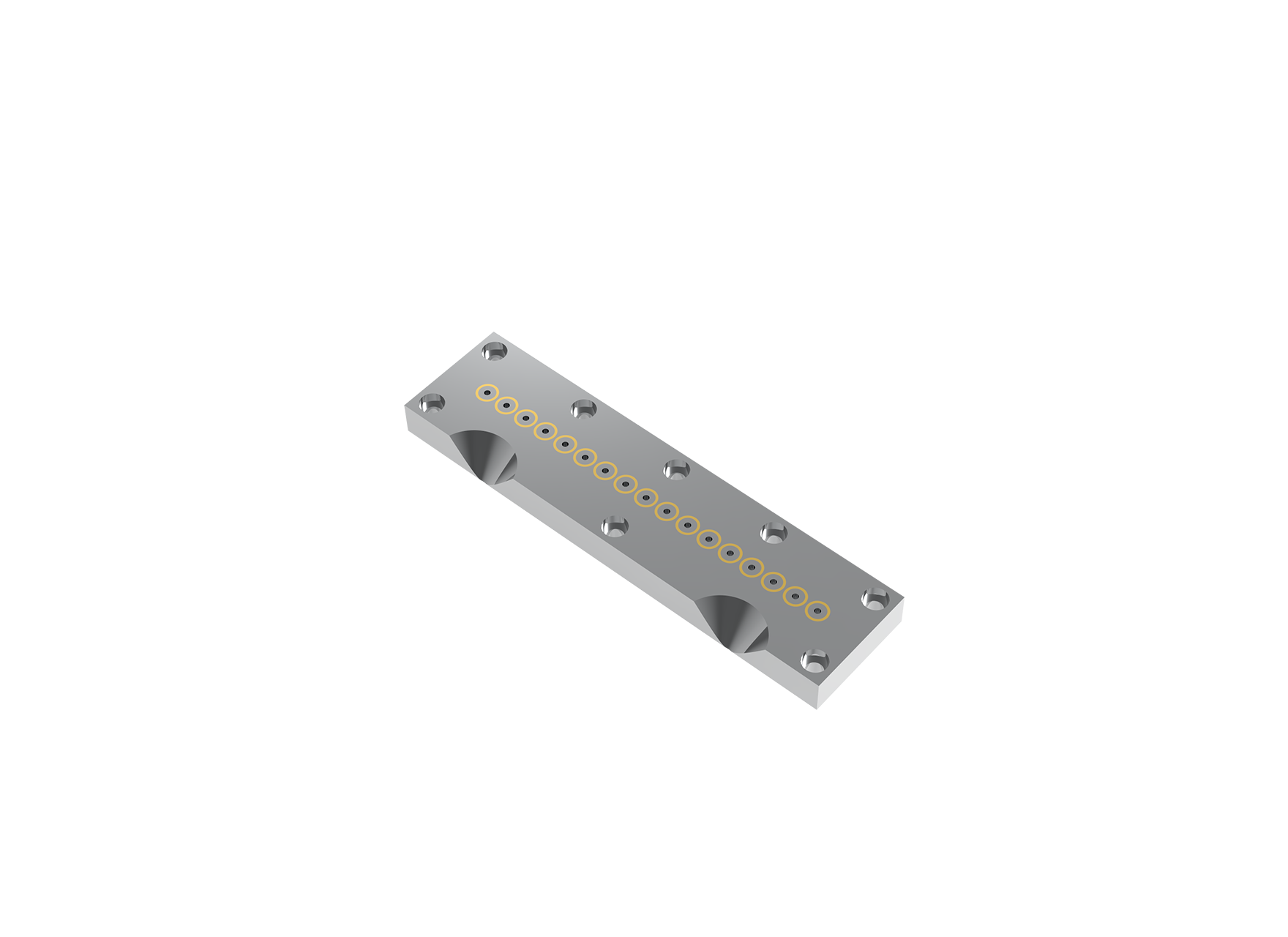

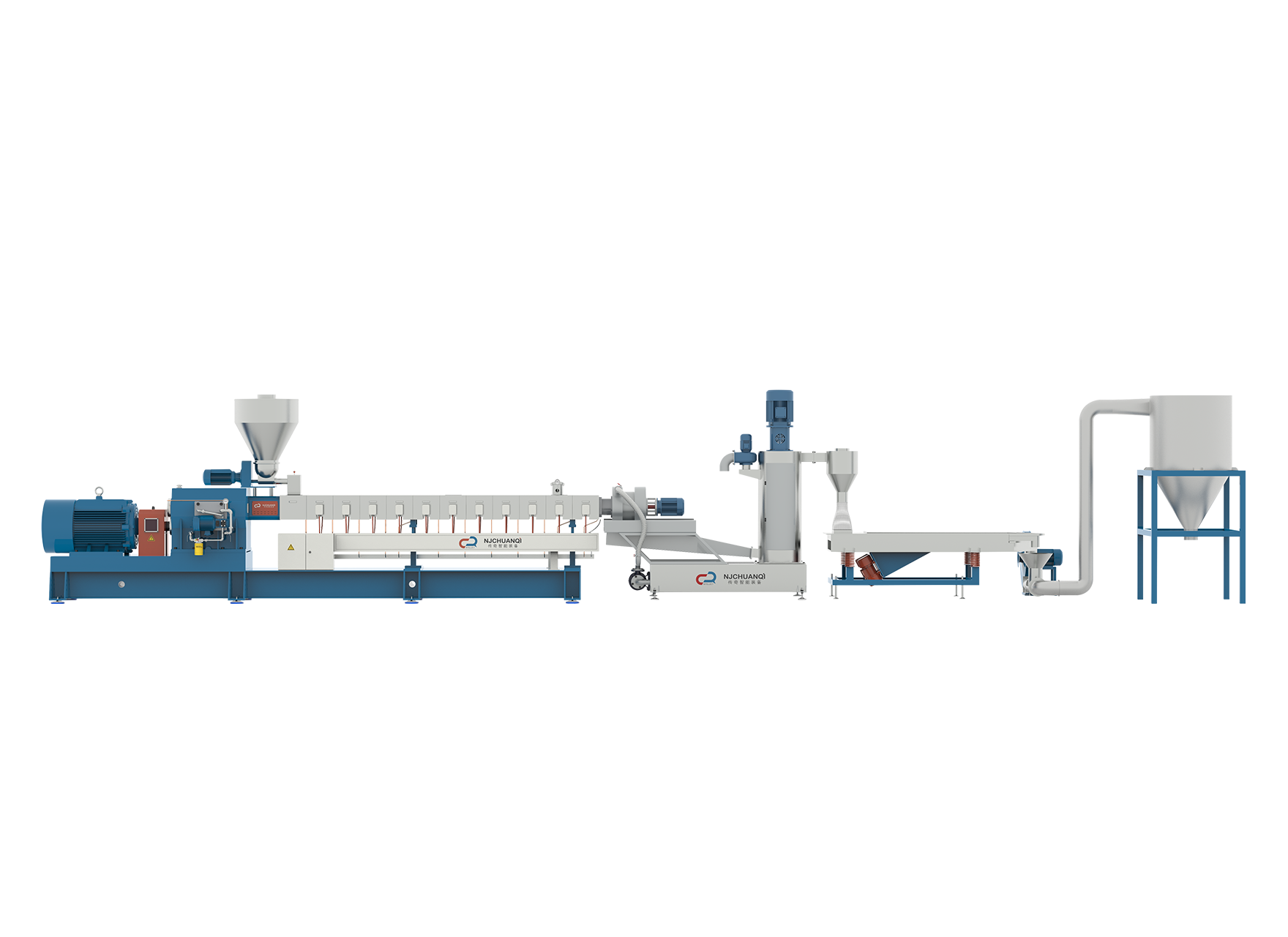

The Roller Granulator works by compacting powder materials between two counter-rotating rollers, which exert high pressure to form dense sheets or ribbons. These ribbons are then broken down into smaller granules through crushing and sieving stages. Because the process relies on mechanical compression without the need for liquid binders or drying, it inherently produces dense and robust particles. The pressure applied during compaction can be finely adjusted to achieve the desired granule hardness. In general, granules made using this method exhibit high mechanical strength, allowing them to withstand handling, transportation, and packaging without excessive breakage or dust generation.

Uniformity in Granule Size and Shape

Granule uniformity is crucial for downstream processes such as coating, blending, and application in automated systems. The Roller Granulator typically produces relatively uniform granules due to the structured and repeatable nature of its compaction and crushing mechanism. By using calibrated sieving equipment and adjustable roller gaps, manufacturers can control the size distribution within a narrow range. While the process does produce some fines and oversized particles, these are often recycled back into the system, improving yield and overall size consistency. In well-optimized production lines, the final granule product shows a high degree of uniformity in both shape and particle size distribution.

Influencing Factors on Strength and Uniformity

Several variables influence the particle quality produced by this type of equipment. The raw material characteristics, including particle size, moisture content, and compressibility, directly impact the resulting granule strength. Poorly prepared feedstock can cause weak or irregular granules. Equipment settings such as roller pressure, roller speed, and feeding rate also affect the final product. Insufficient pressure may produce friable granules, while excessive pressure can cause overly dense and brittle ones. In addition, the condition and design of the rollers, such as their surface texture and alignment, play a role in ensuring consistent compaction and uniform granule formation.

Advantages in Industrial Applications

The strong and uniform granules produced by this dry granulation method offer distinct benefits in practical applications. In the fertilizer industry, for example, granules with sufficient strength reduce the risk of caking and improve flowability during mechanical spreading. In the pharmaceutical sector, uniform particle size enhances dosage accuracy and dissolution profiles. Furthermore, the dry process reduces energy consumption and eliminates the need for solvents or drying steps, resulting in a cleaner and more sustainable production method. These qualities make the technology especially attractive for industries focused on high-throughput, low-waste operations.

Conclusion: High Consistency and Strength Through Controlled Compaction

In conclusion, granules produced by a Roller Granulator demonstrate high mechanical strength and reliable uniformity when the process is properly configured and raw materials are adequately prepared. The dry compaction approach not only yields durable particles but also allows for tight control over size distribution, ensuring suitability for a range of demanding applications. With proper maintenance and calibration, this equipment offers a cost-effective and efficient solution for producing high-quality granules in various industrial sectors.

English

English 中文简体

中文简体 русский

русский عربى

عربى +86-189 1339 2785

+86-189 1339 2785