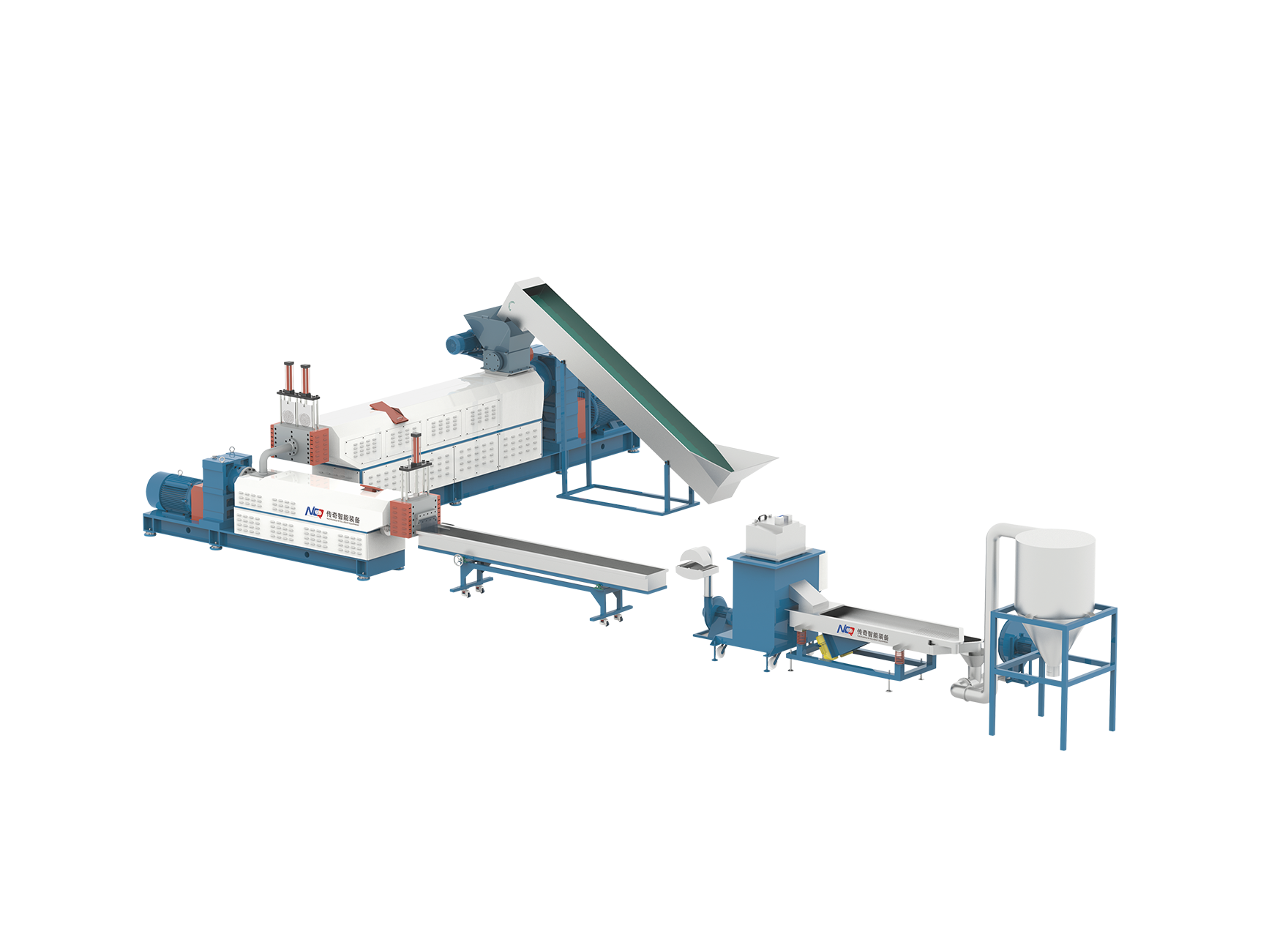

Energy consumption is a critical factor in selecting plastic extrusion equipment, impacting both operational costs and environmental footprint. Two commonly used types are the Small Scale Plastic Extruder and the Twin Screw Plastic Extruder. Although both serve to process plastics, their energy efficiency and consumption patterns differ significantly due to design, scale, and intended applications.

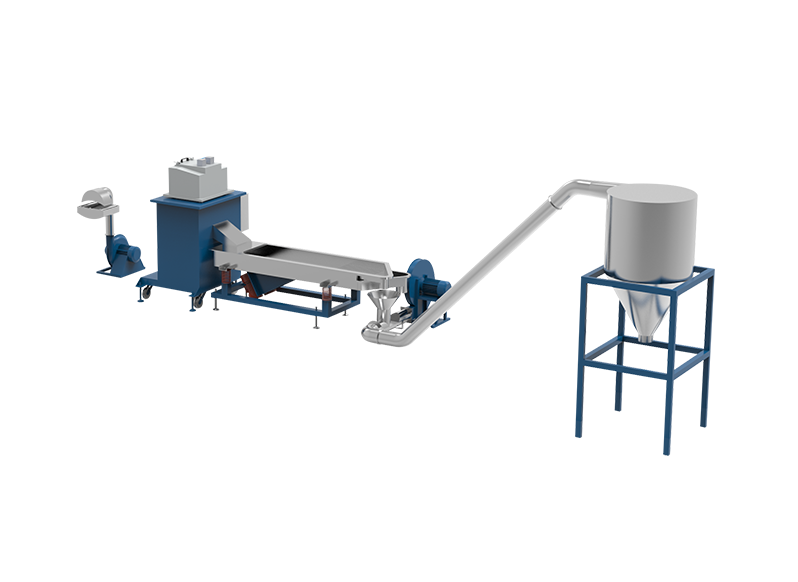

Energy Usage in Small-Scale Plastic Extruder

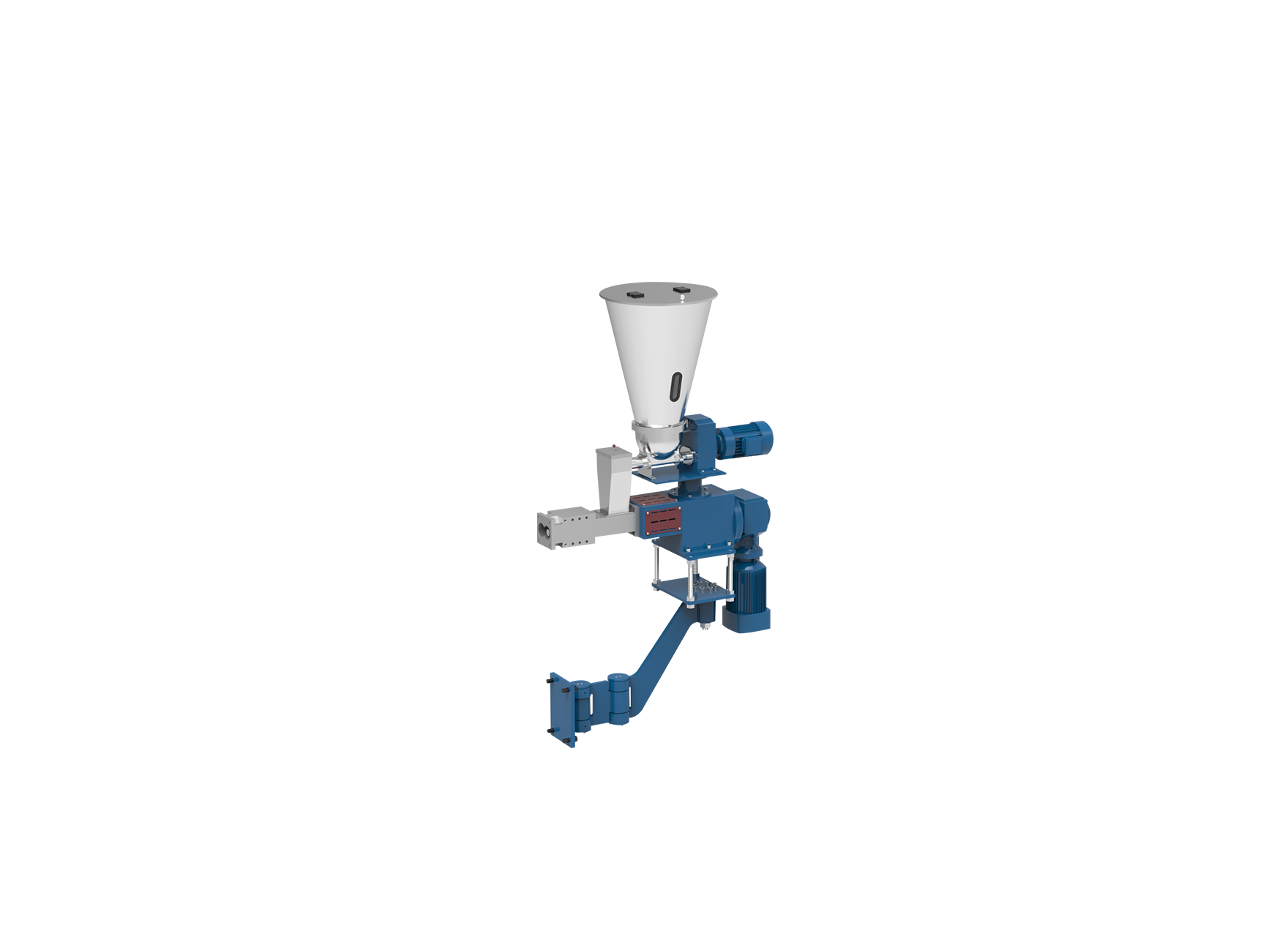

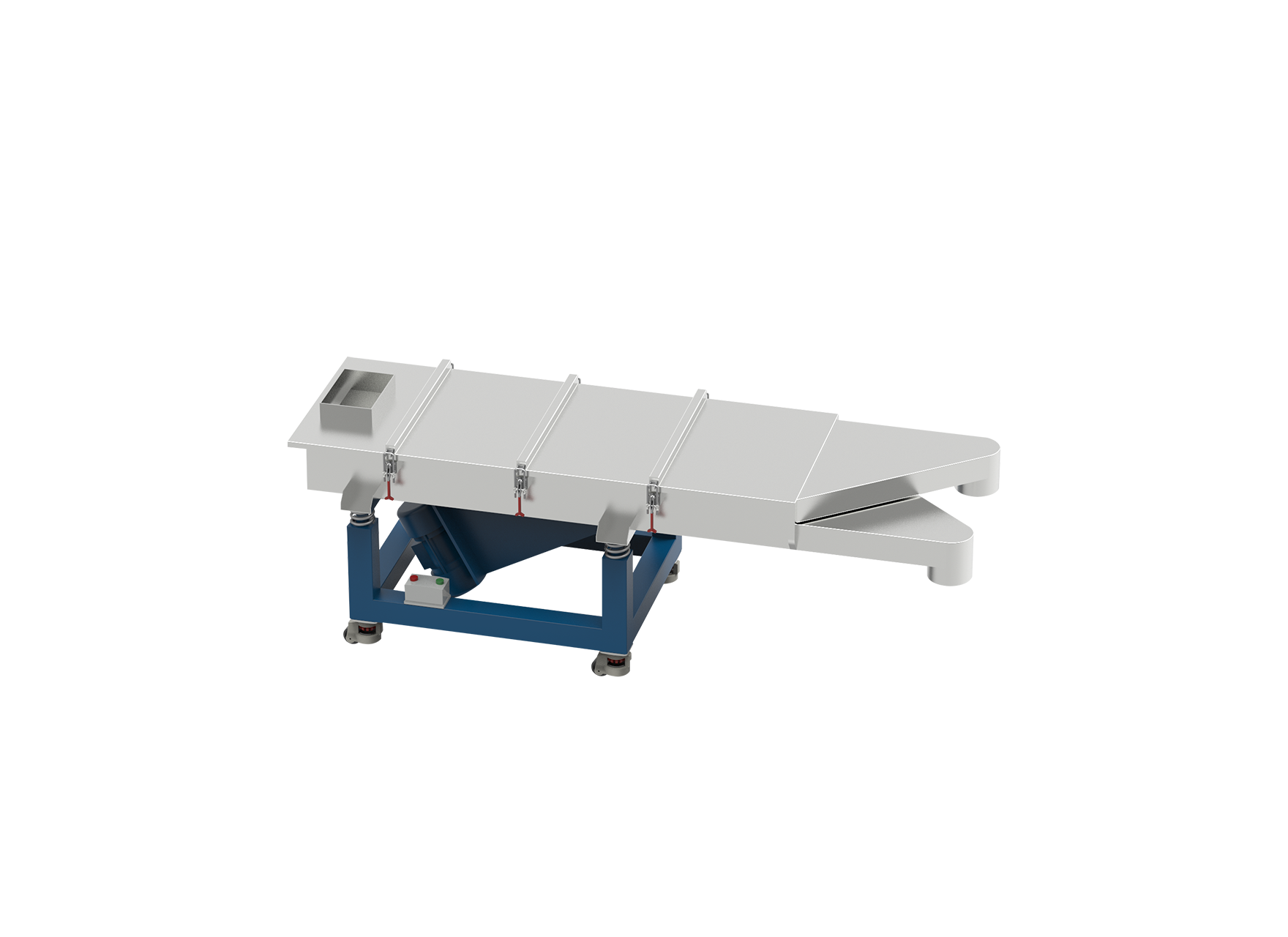

Small-scale plastic Extruders are typically designed for lower volume production or localized recycling projects. Due to their compact size and simpler construction, these extruders generally consume less power compared to large industrial machines. Their energy demands align well with decentralized operations or small workshops where electricity availability or costs might be limited.

However, because of their smaller capacity, these extruders often operate at lower throughput rates. This means that while the total power consumption per hour is lower, the energy used per kilogram of processed plastic might be relatively higher than more efficient large-scale machines. Still, their overall energy footprint is modest, making them suitable for sustainable small-batch manufacturing or community recycling.

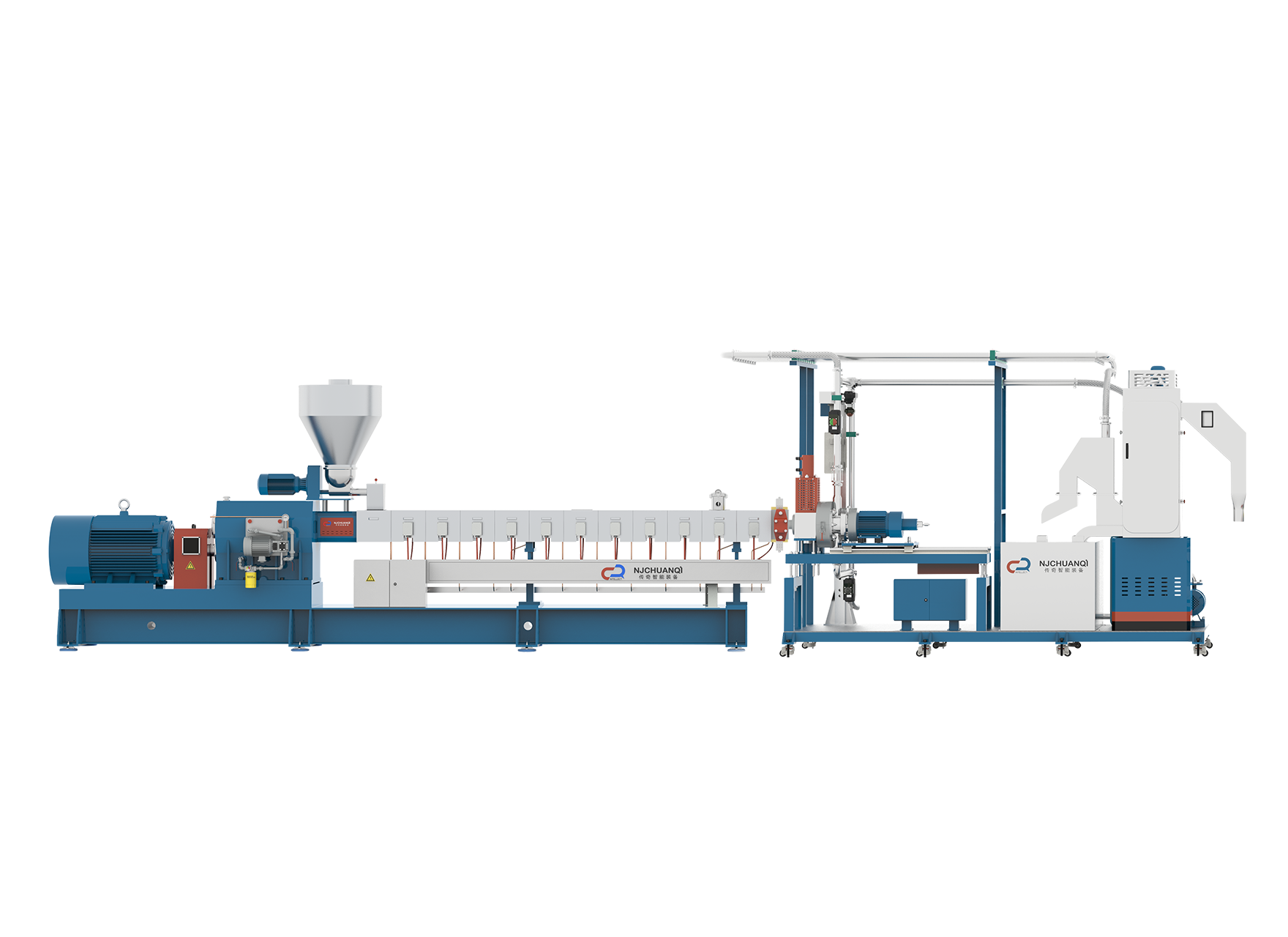

Energy Consumption of Twin Screw Plastic Extruder

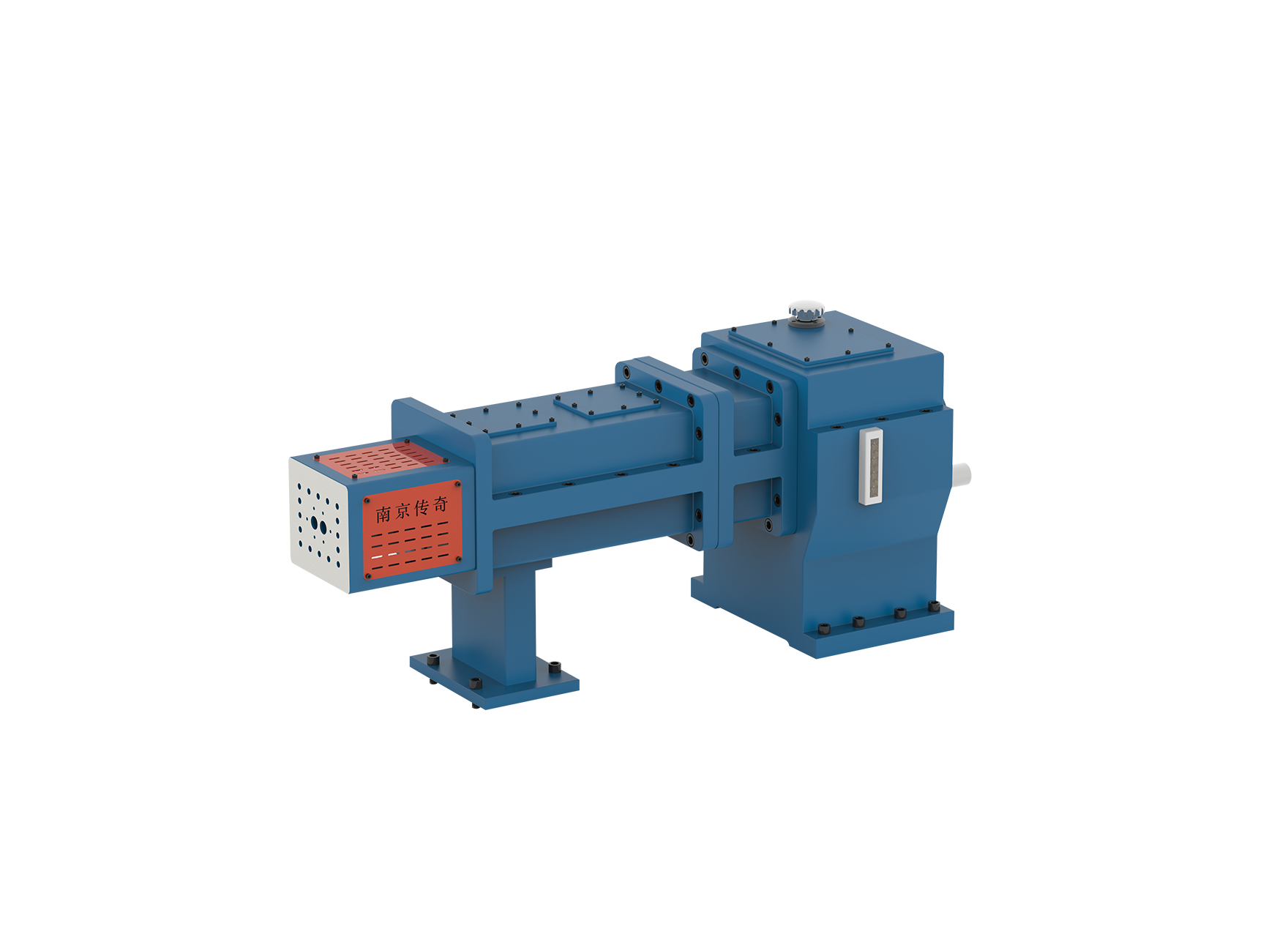

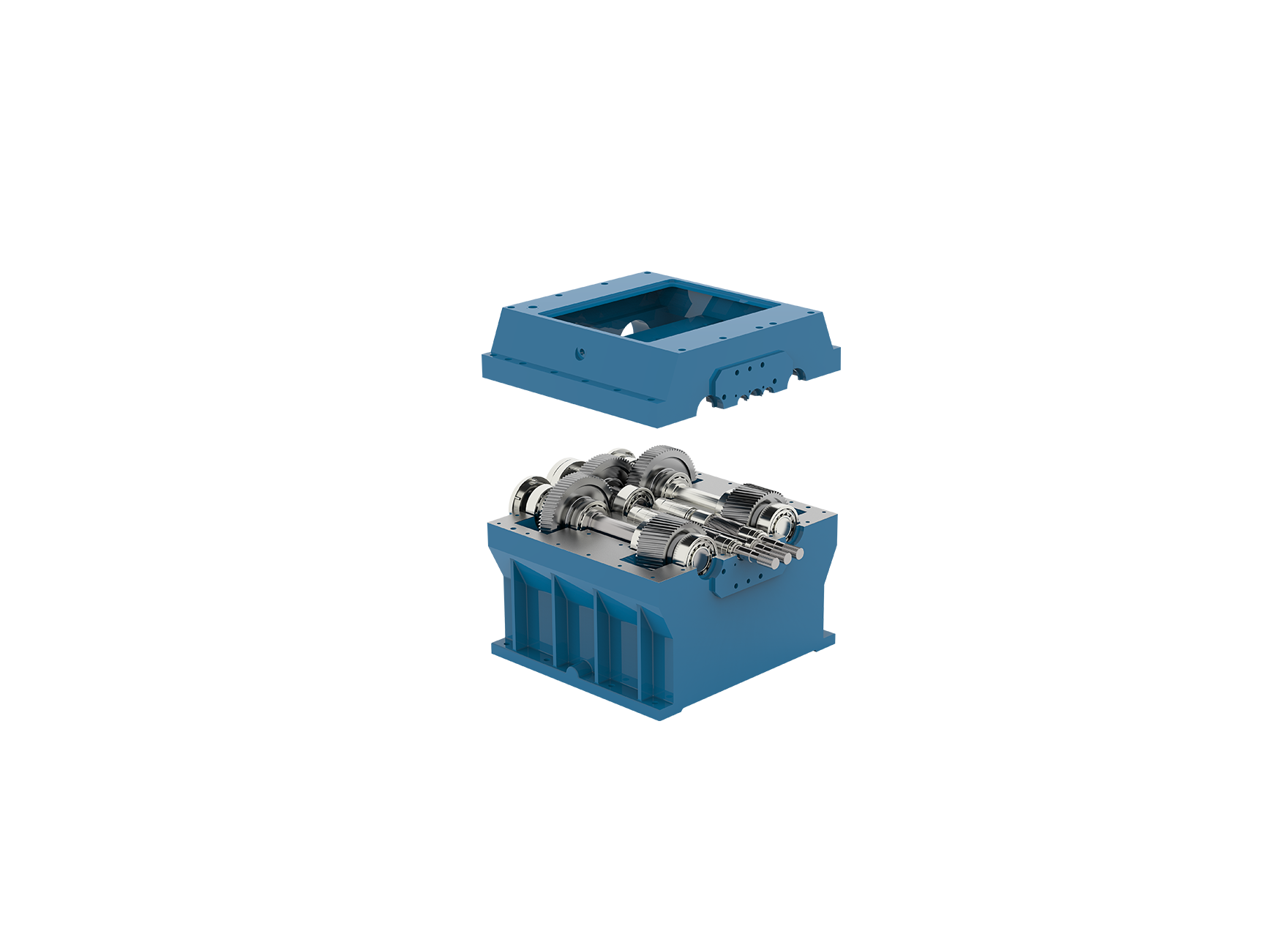

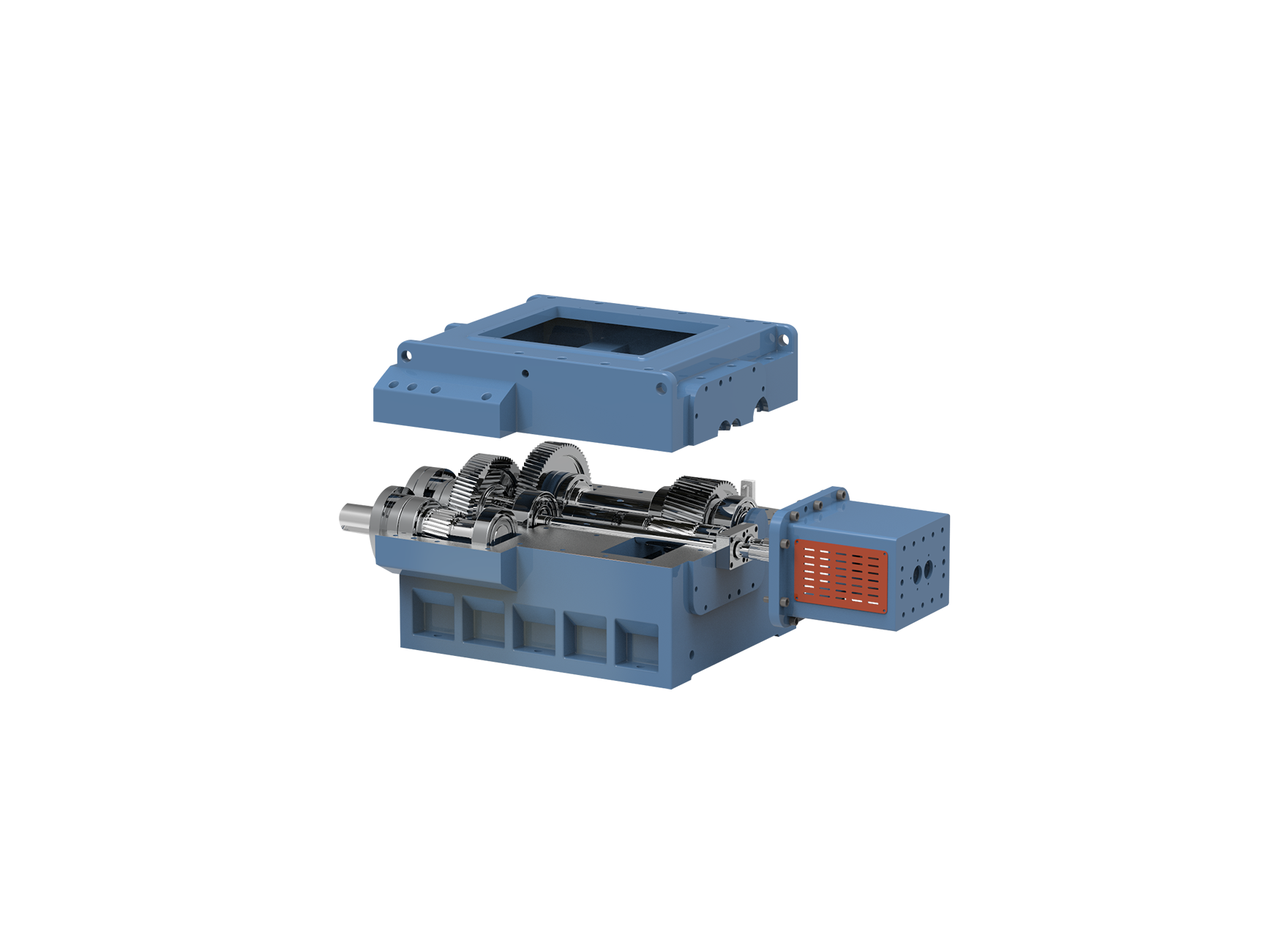

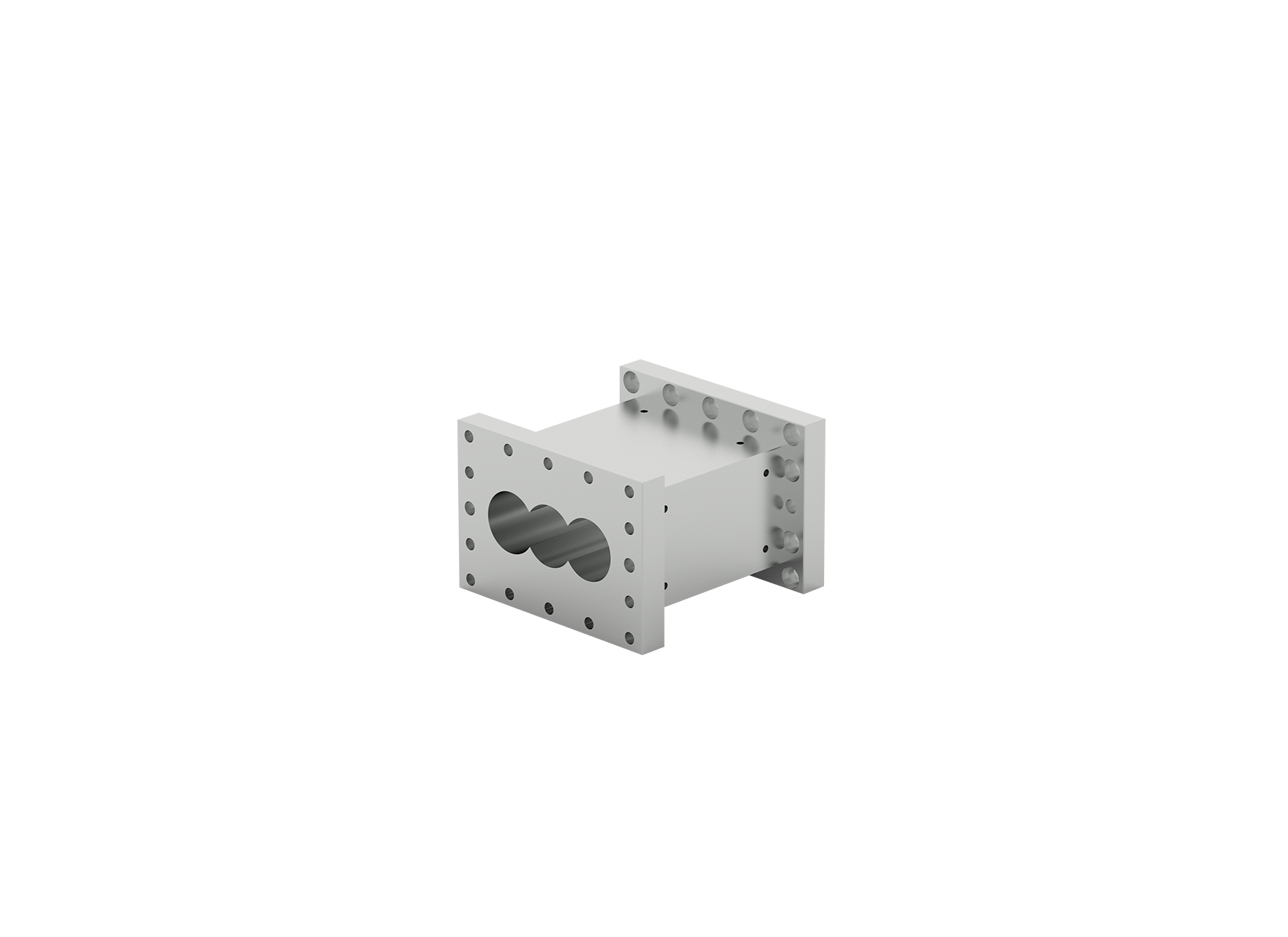

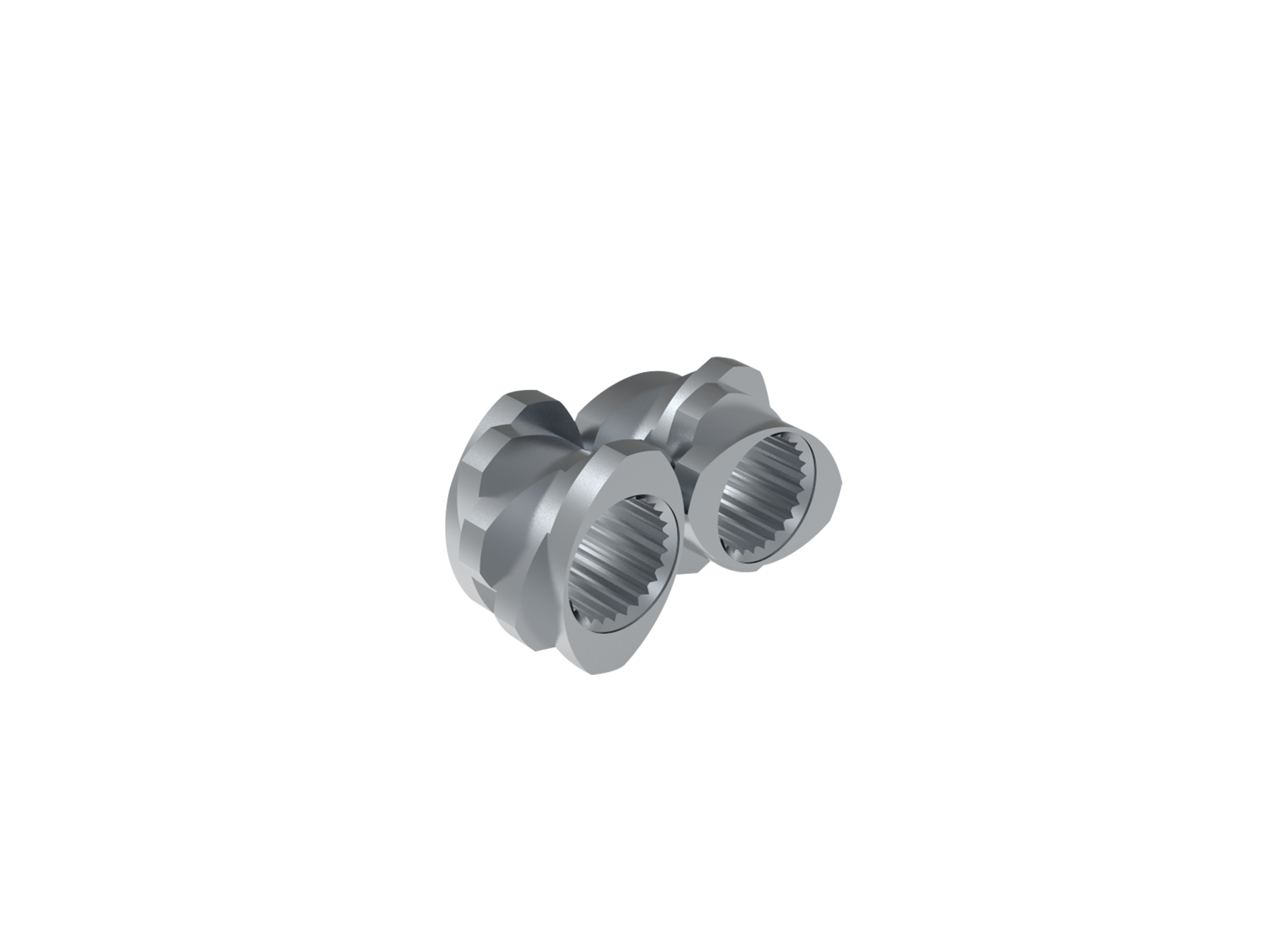

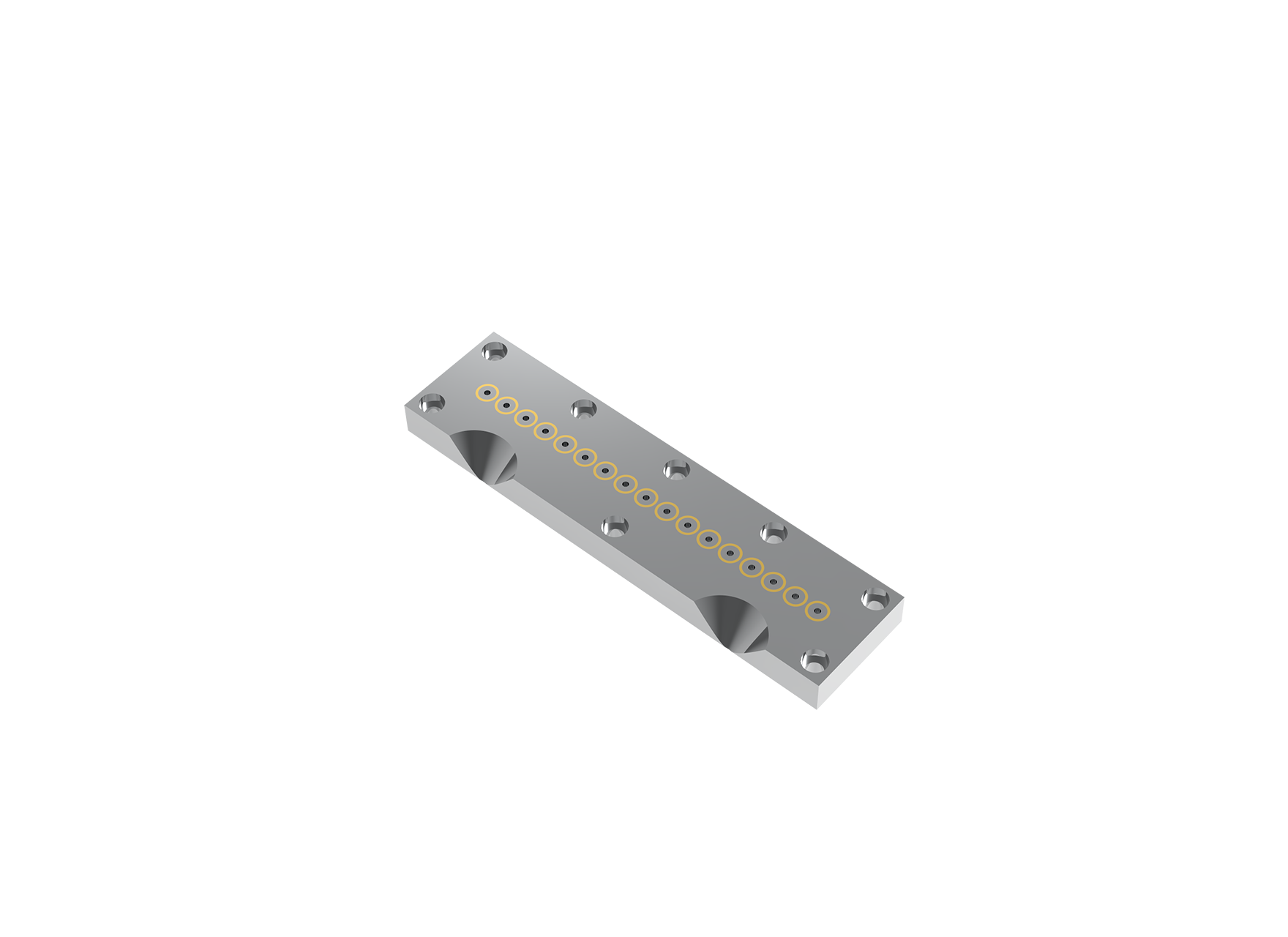

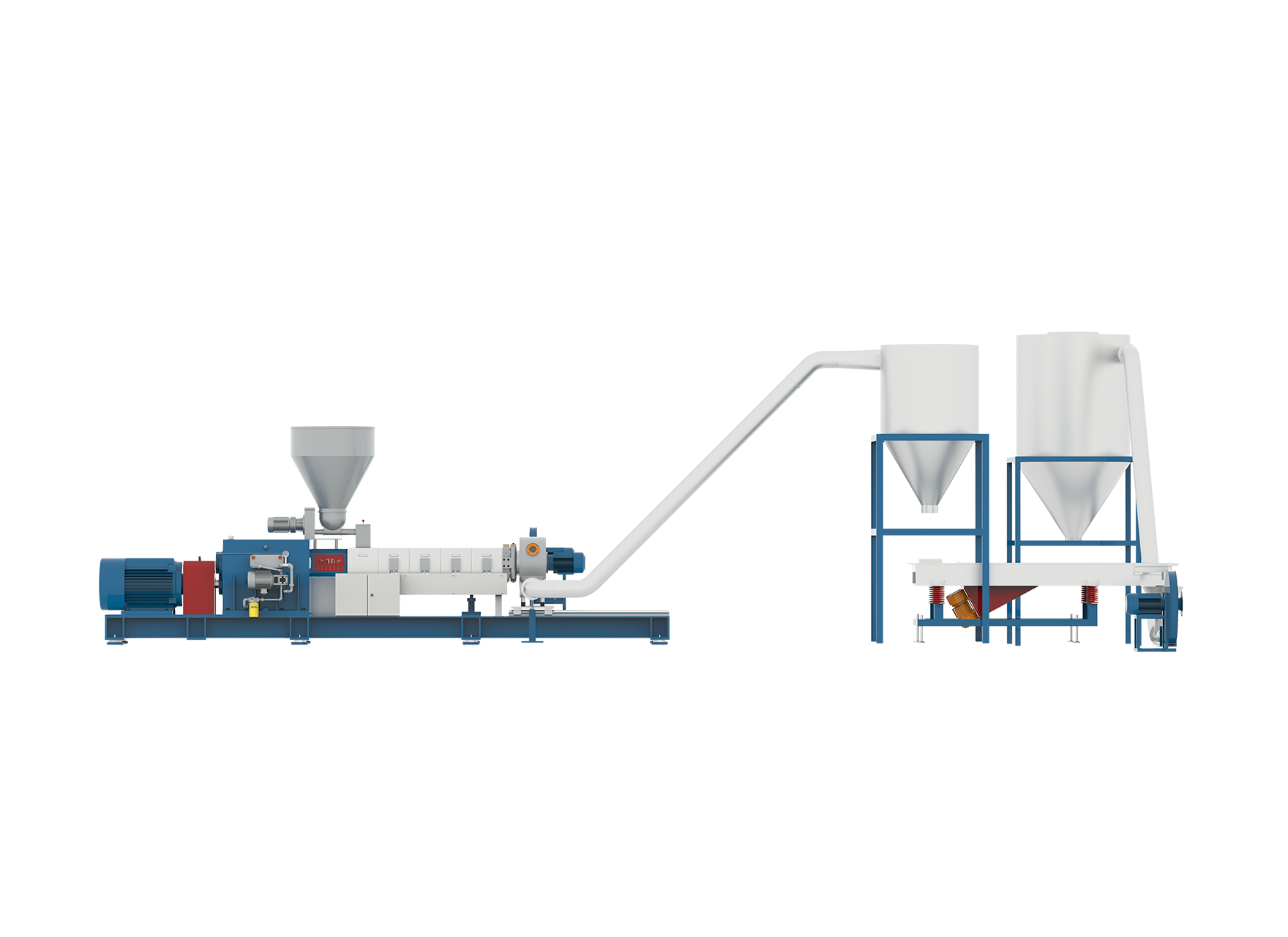

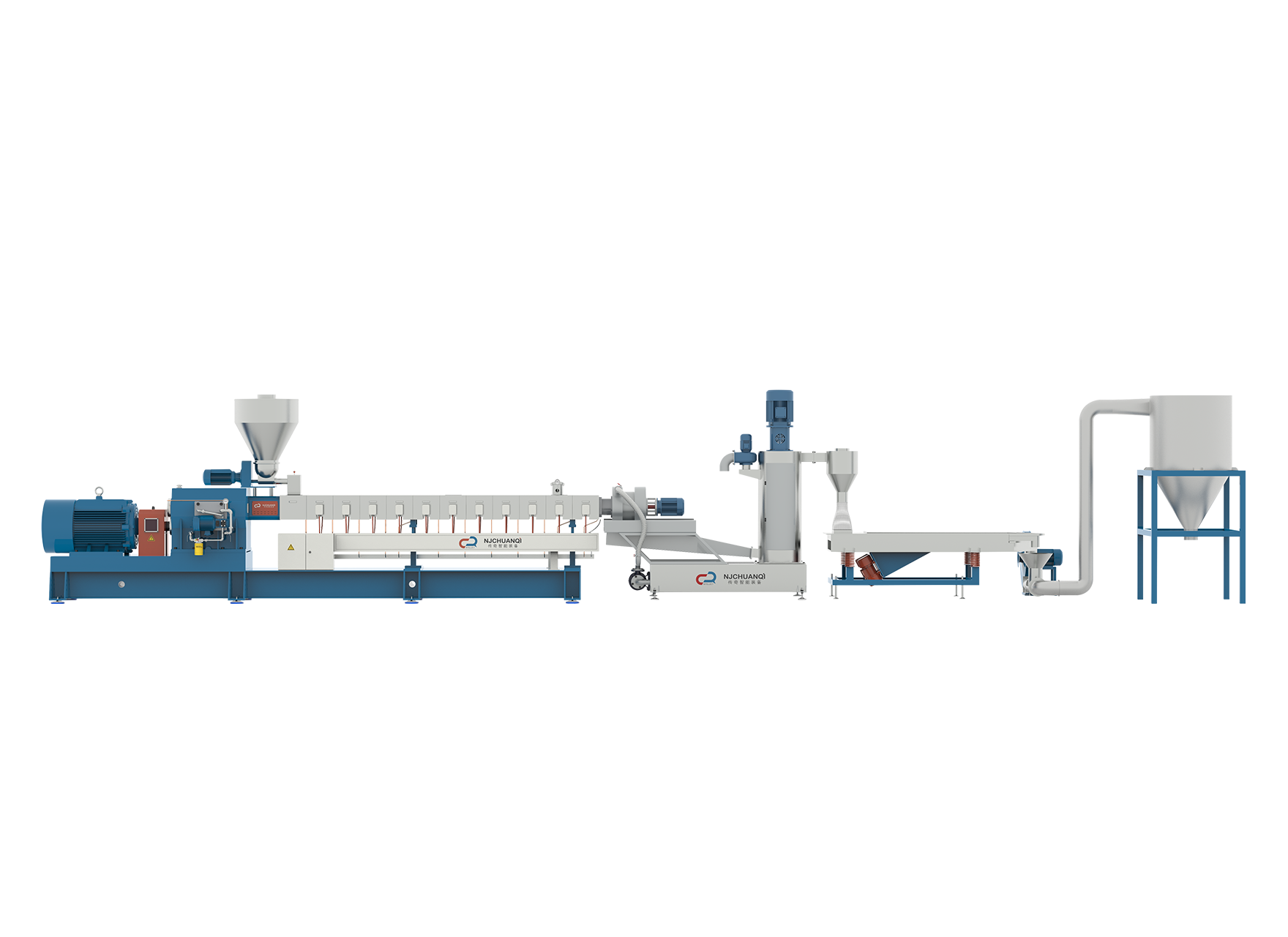

The Twin Screw Plastic Extruder is widely recognized for its versatility and efficiency in handling complex plastic formulations, including blends and composites. Its design features two intermeshing screws that provide better mixing and more uniform melting. This design inherently requires more power to drive the screws and maintain the necessary torque, causing higher energy consumption compared to simpler single-screw extruders.

Despite the higher energy use, twin screw extruders tend to be more efficient in material processing. Their good mixing and processing capabilities often result in higher output quality and reduced waste, indirectly contributing to energy savings by reducing the need for reprocessing or scrap handling.

Energy Efficiency Considerations

Both types of extruders have opportunities for improving energy efficiency through technological advancements. For small-scale plastic extruders, incorporating variable frequency drives (VFDs) can optimize motor speed based on processing needs, reducing unnecessary power use. Proper insulation and temperature control also help in reducing heat loss.

Twin screw extruders benefit from precise control systems that adjust screw speed, barrel temperature, and feed rates to optimize energy use without compromising product quality. Additionally, modern twin screw machines may employ energy recovery systems and high-efficiency motors to reduce their overall consumption.

Balancing Energy Consumption and Productivity

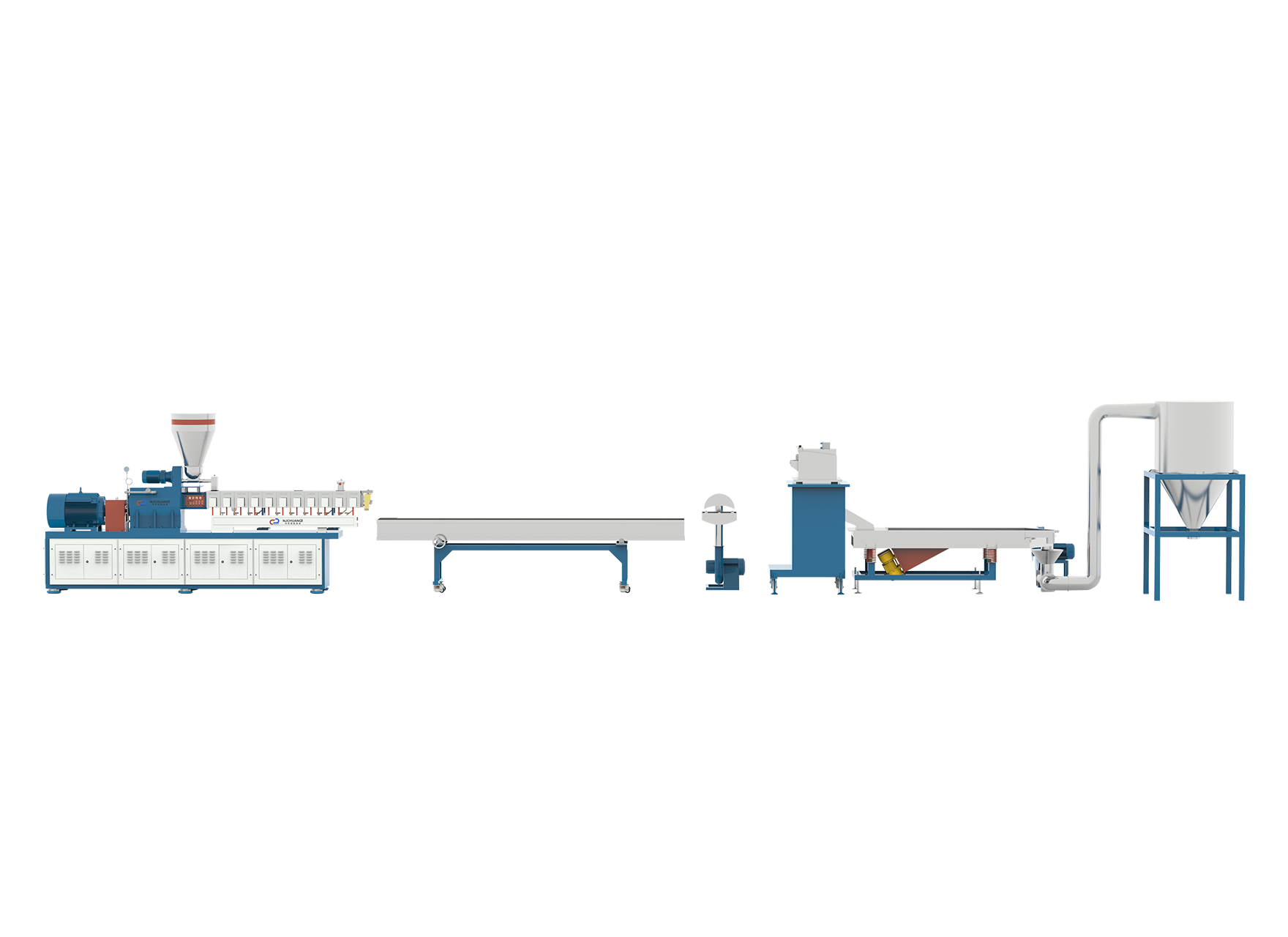

Choosing between a small scale plastic extruder and a twin screw plastic extruder depends largely on production goals. Small-scale extruders offer lower absolute energy consumption, are suited for limited batch sizes, but may be less energy-efficient per unit of output. Twin screw extruders, while consuming more power, provide higher productivity and material versatility, potentially causing better energy utilization in large-scale or complex applications.

Environmental and Economic Impacts

Lower energy consumption in small-scale extruders means reduced operational costs and smaller carbon footprints, particularly beneficial for eco-conscious or budget-limited users. Meanwhile, twin screw extruders' enhanced processing efficiency can justify their higher energy use by improving product quality and minimizing waste, causinglong-term sustainability benefits.

Conclusion

Understanding the energy consumption characteristics of both small scale plastic extruders and twin screw plastic extruders is essential for making informed equipment choices. While small scale extruders consume less power overall, twin screw machines offer process efficiencies that may offset their higher energy demands. Ultimately, selecting the right extruder involves balancing energy use with productivity, material requirements, and sustainability goals.

English

English 中文简体

中文简体 русский

русский عربى

عربى +86-189 1339 2785

+86-189 1339 2785