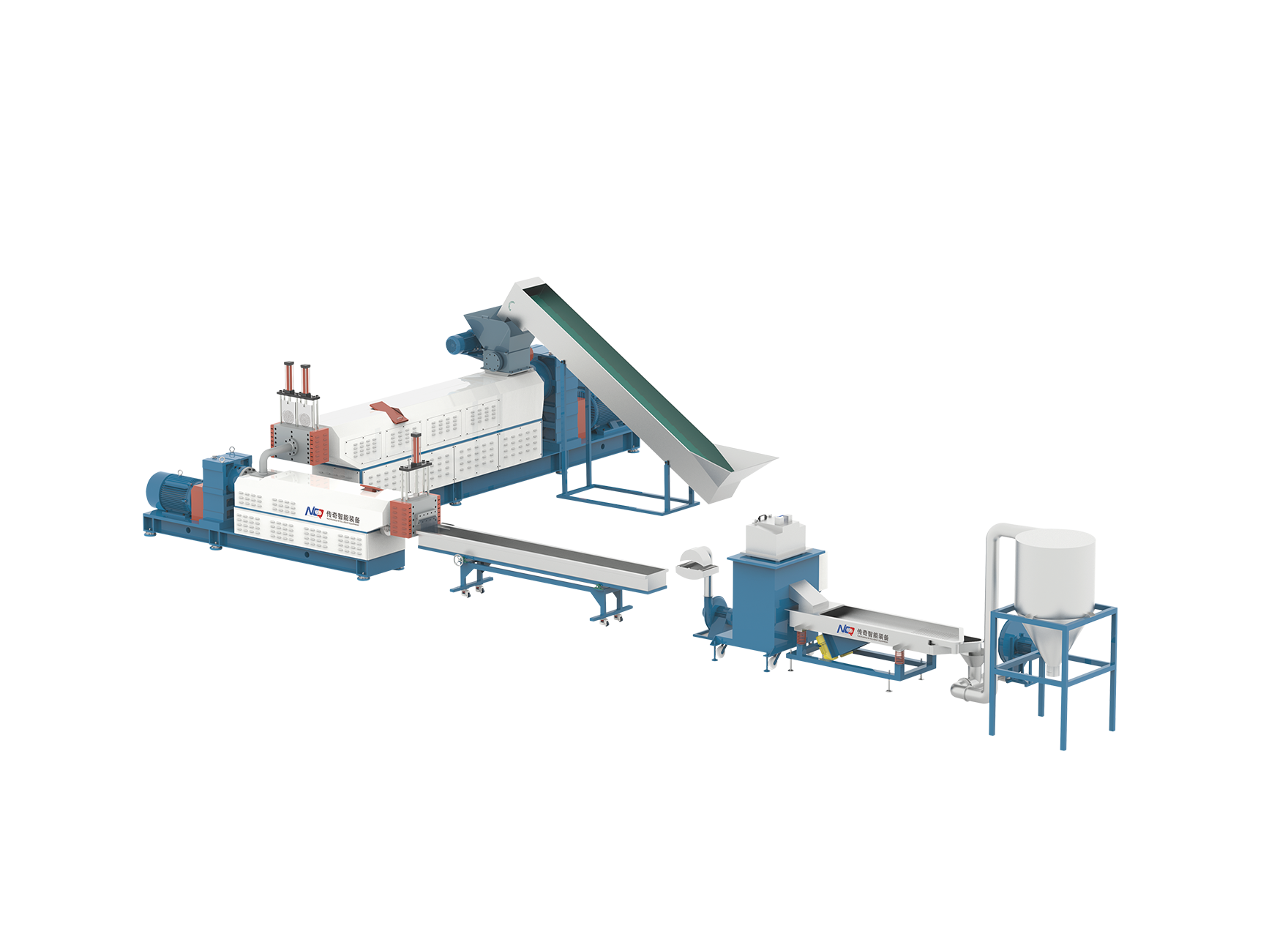

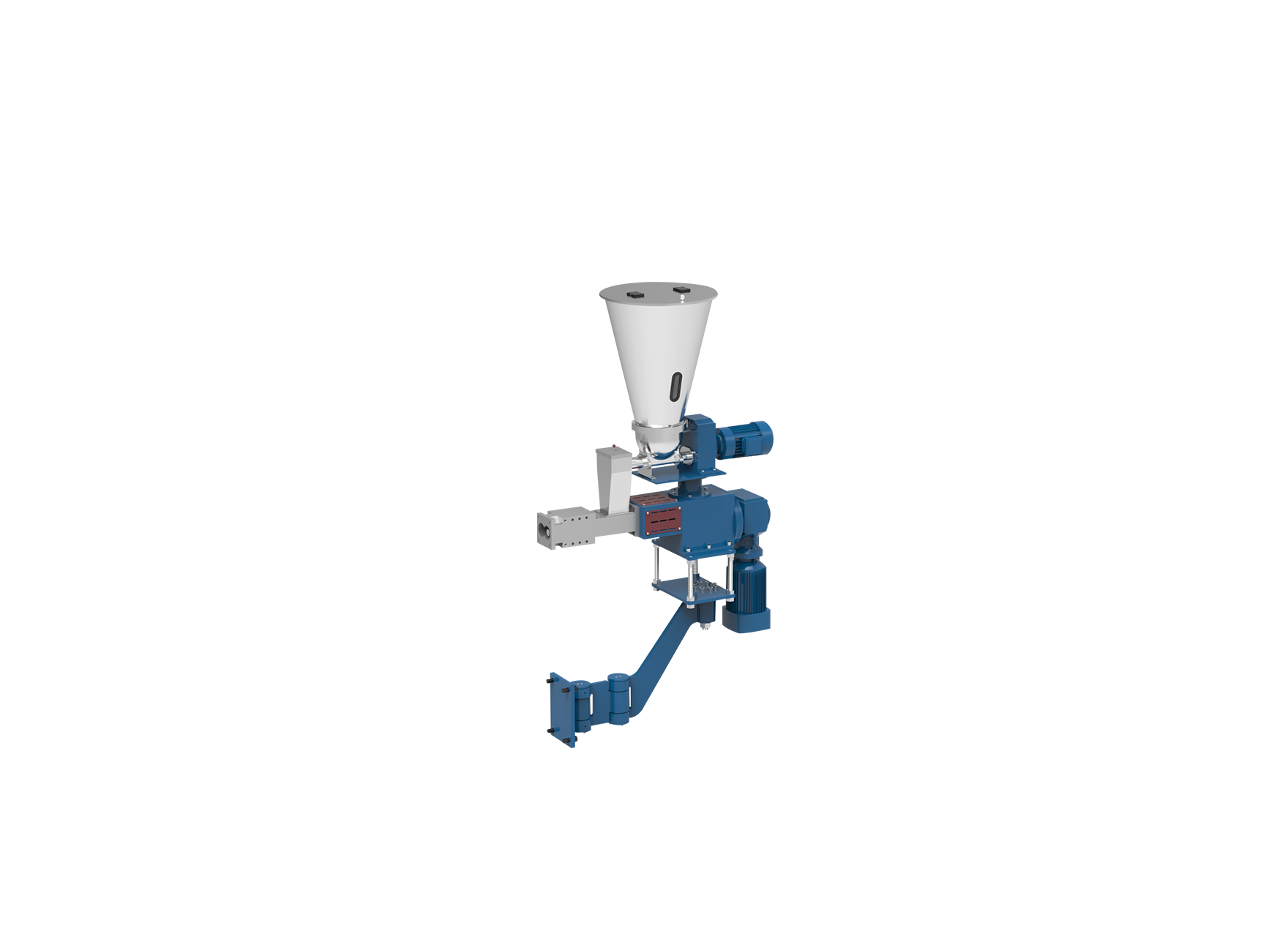

When evaluating plastic processing technologies, it is essential to consider their environmental footprint. The Polymer Extruder Machine and the Plasticpreneur Extruder play significant roles in plastic manufacturing and recycling, but their environmental impacts differ due to scale, design, and application. Understanding these differences helps businesses and communities adopt more sustainable practices.

Energy Consumption and Efficiency

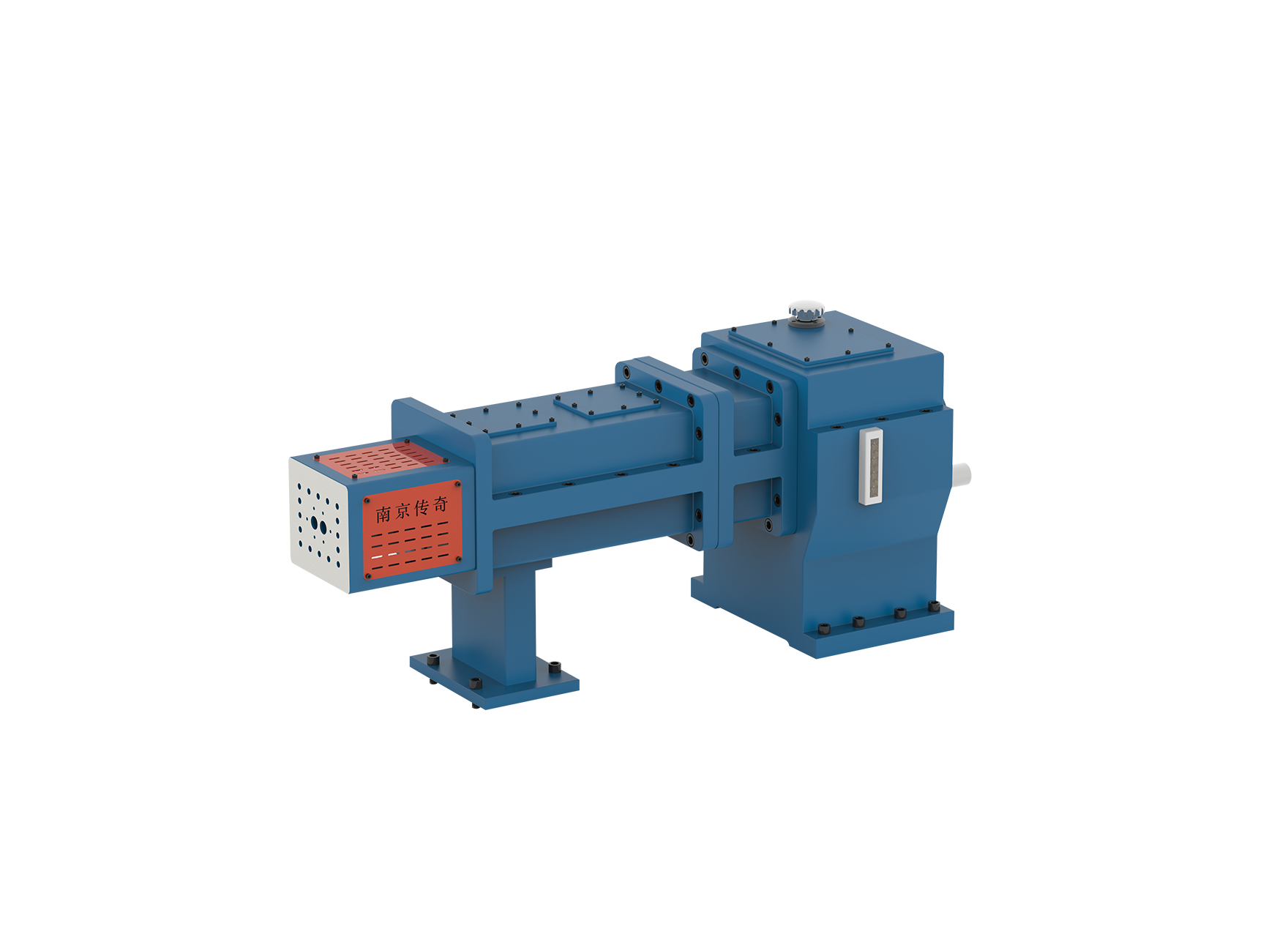

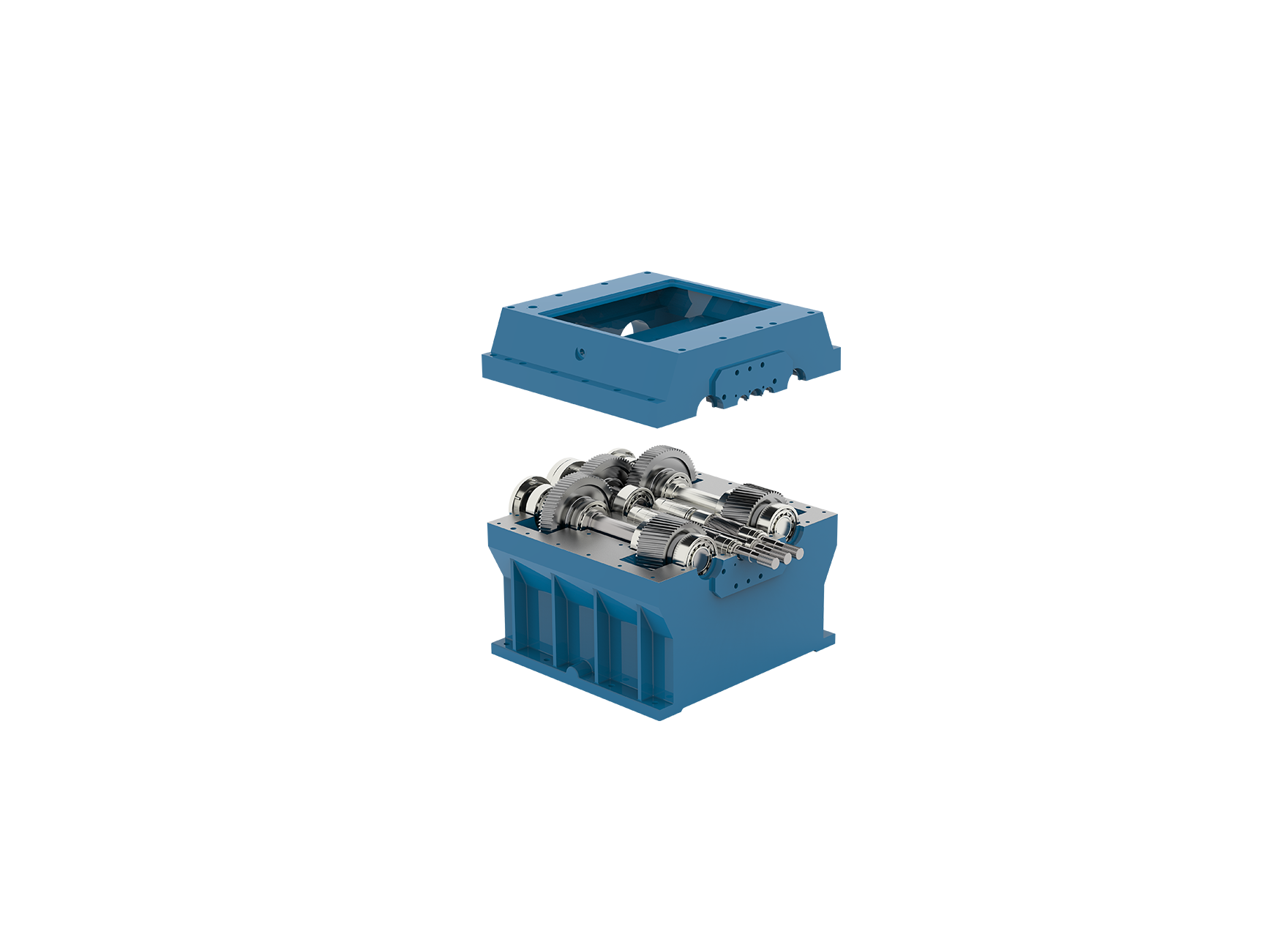

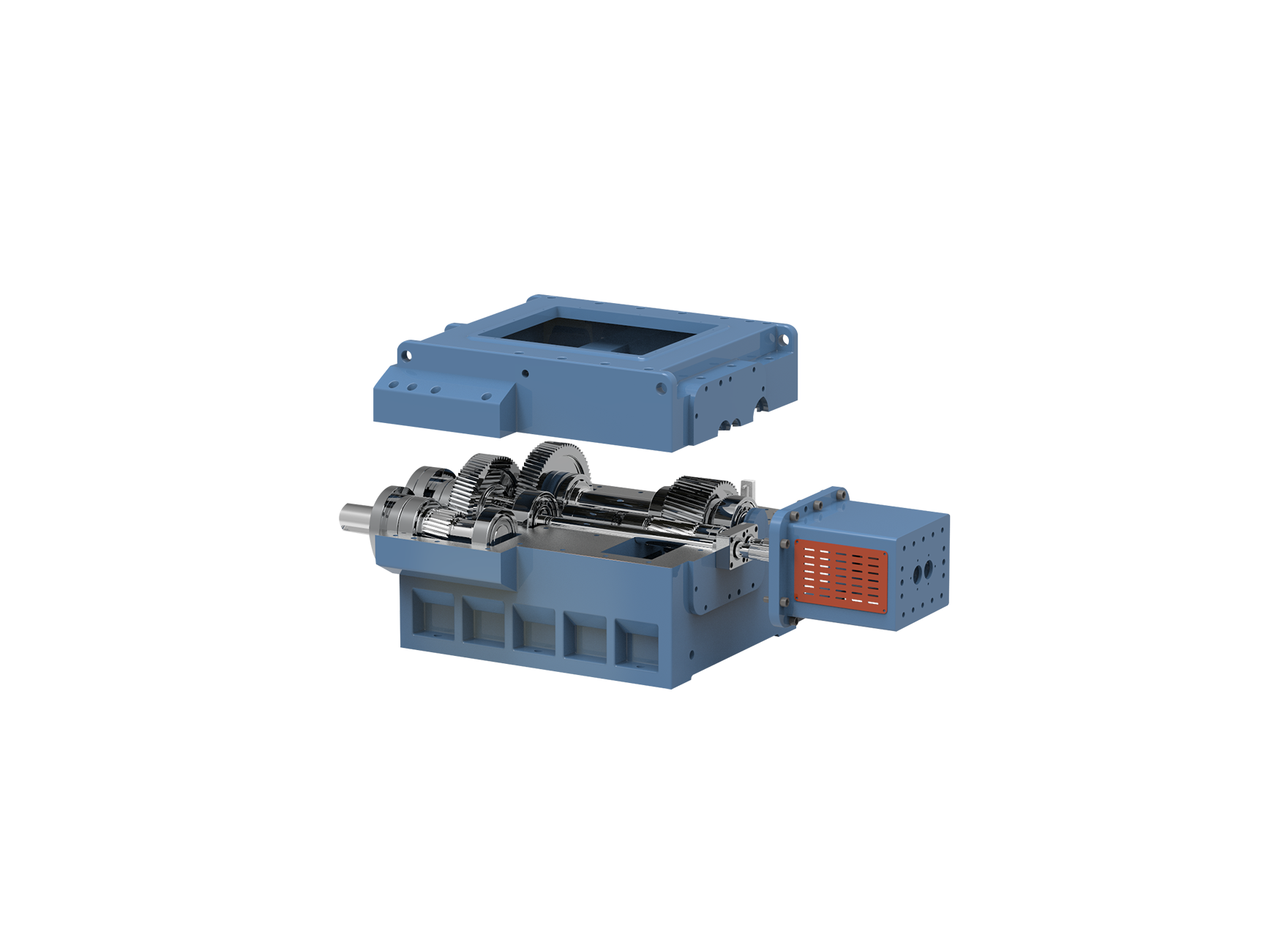

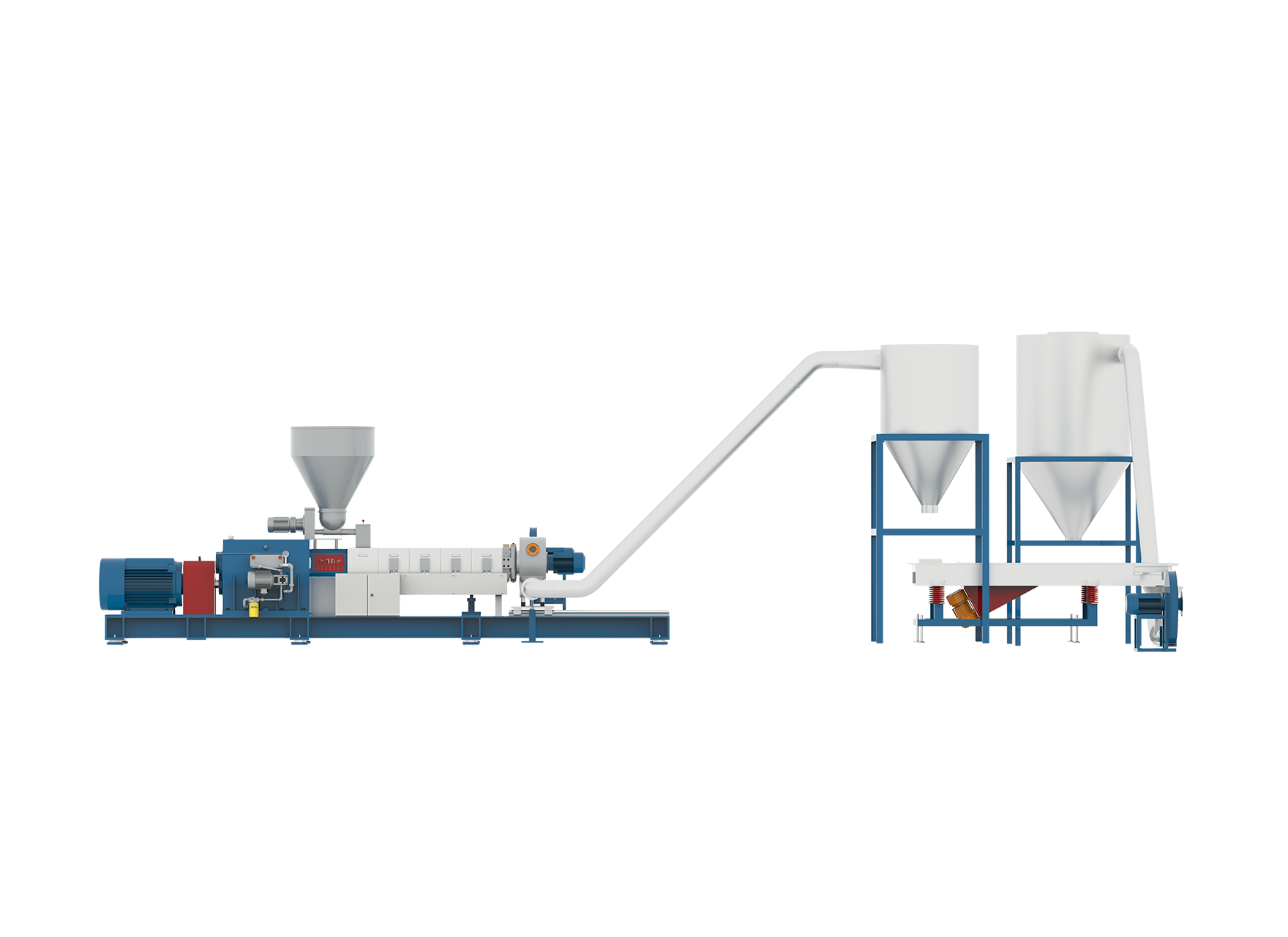

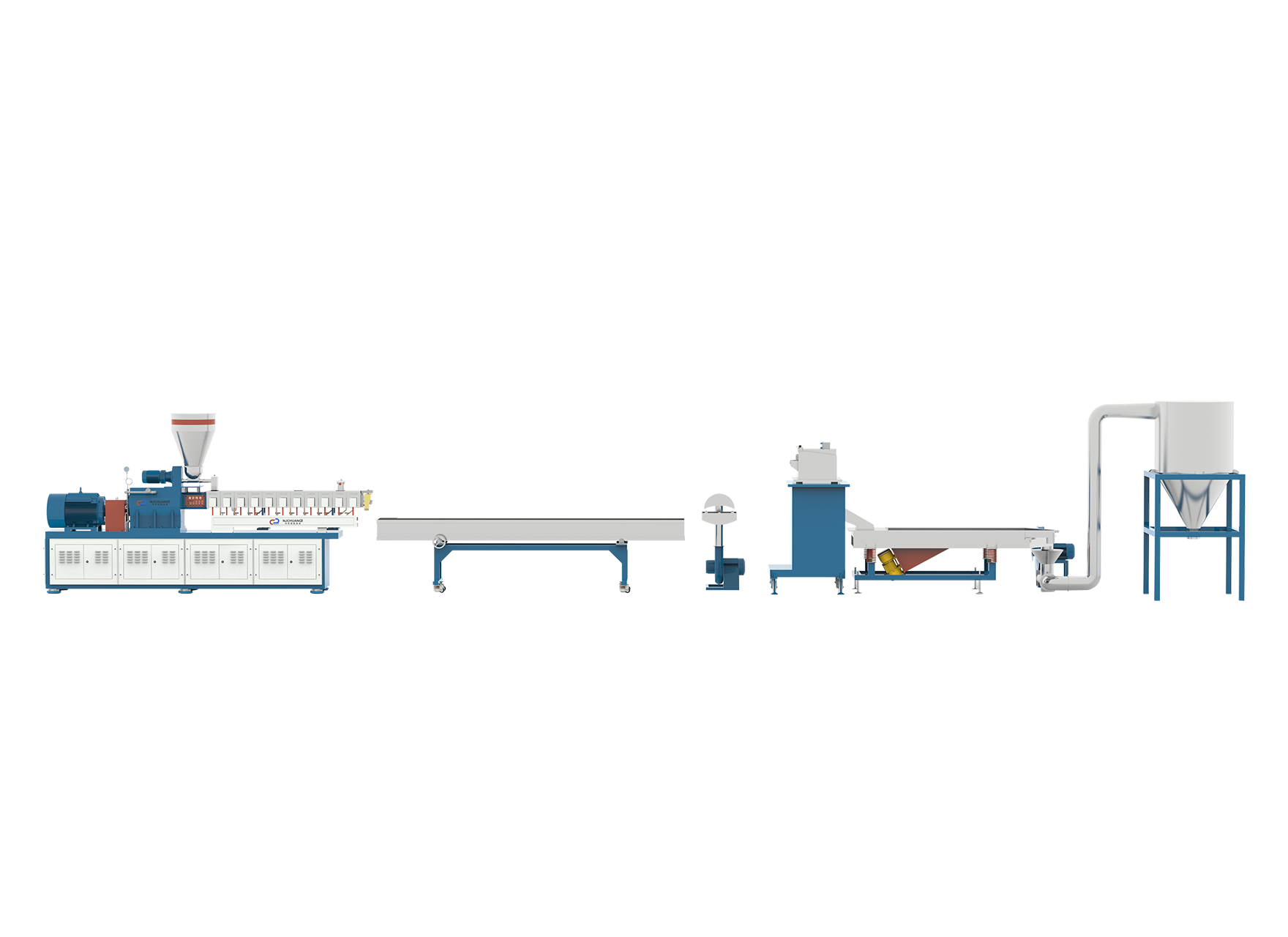

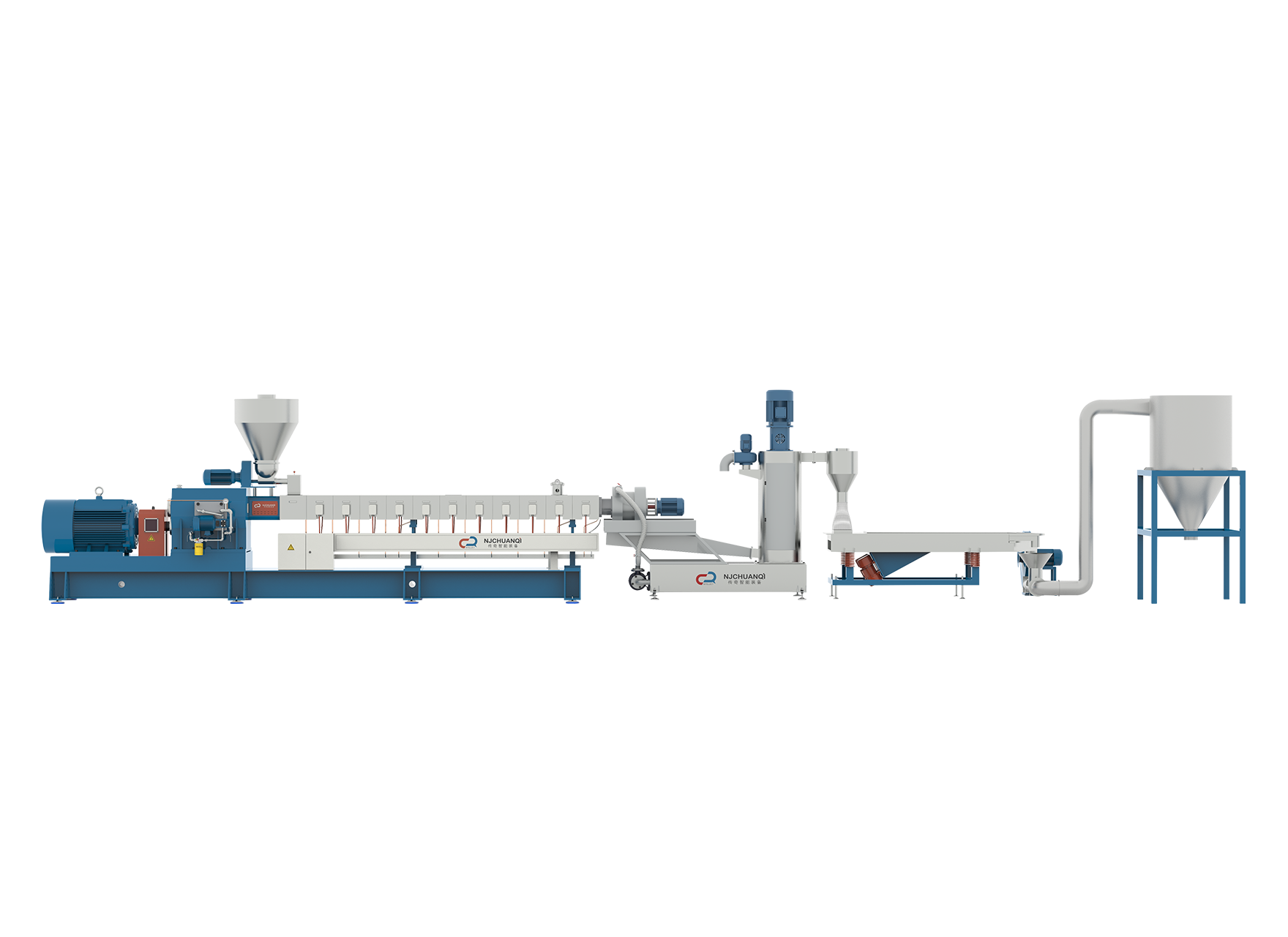

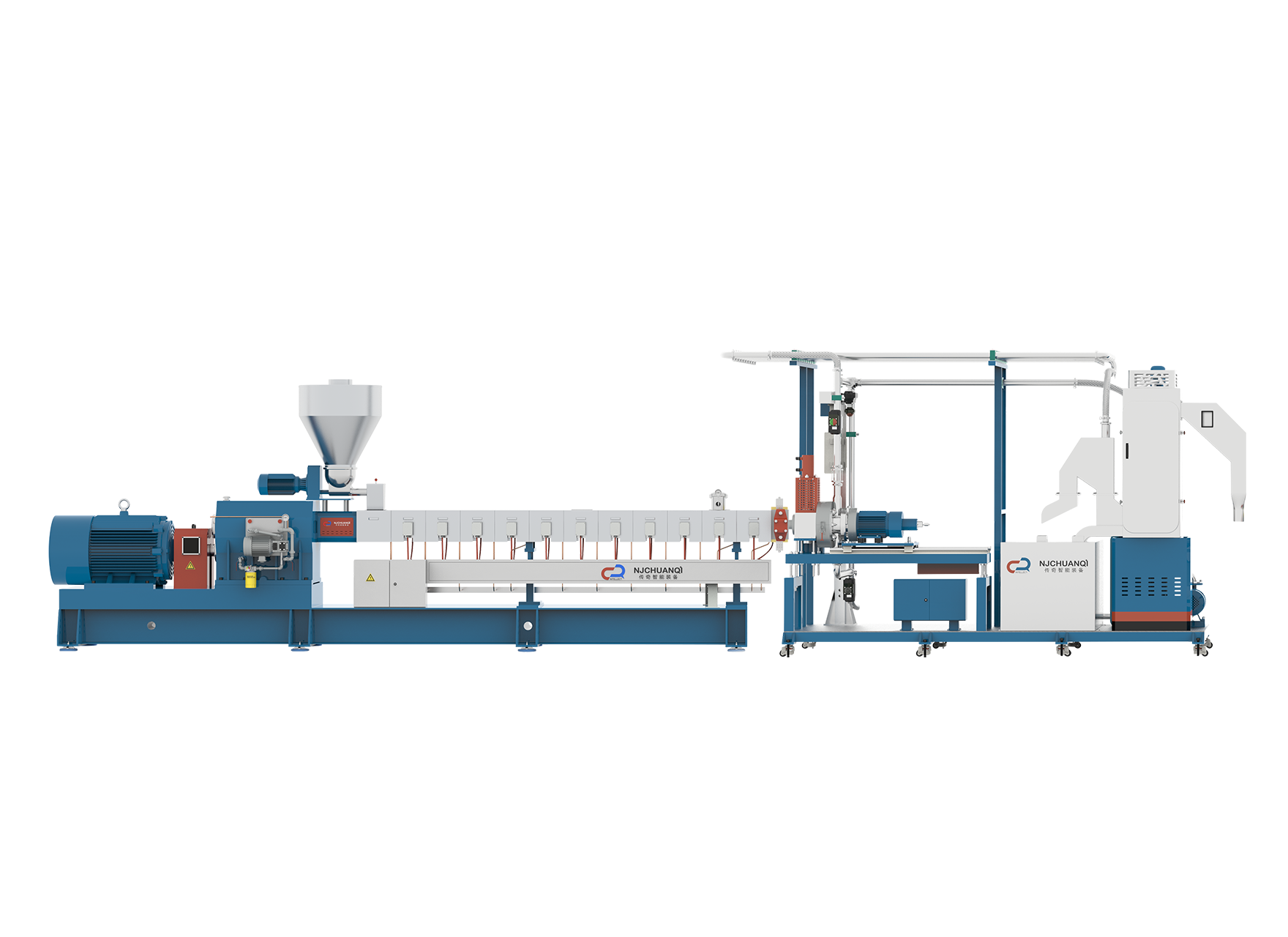

The energy required to operate plastic extrusion equipment directly affects the environmental impact. Large-scale polymer extrusion machines typically consume substantial power because of their higher capacity and continuous operation. This energy demand often correlates with increased greenhouse gas emissions, especially if the electricity comes from non-renewable sources.

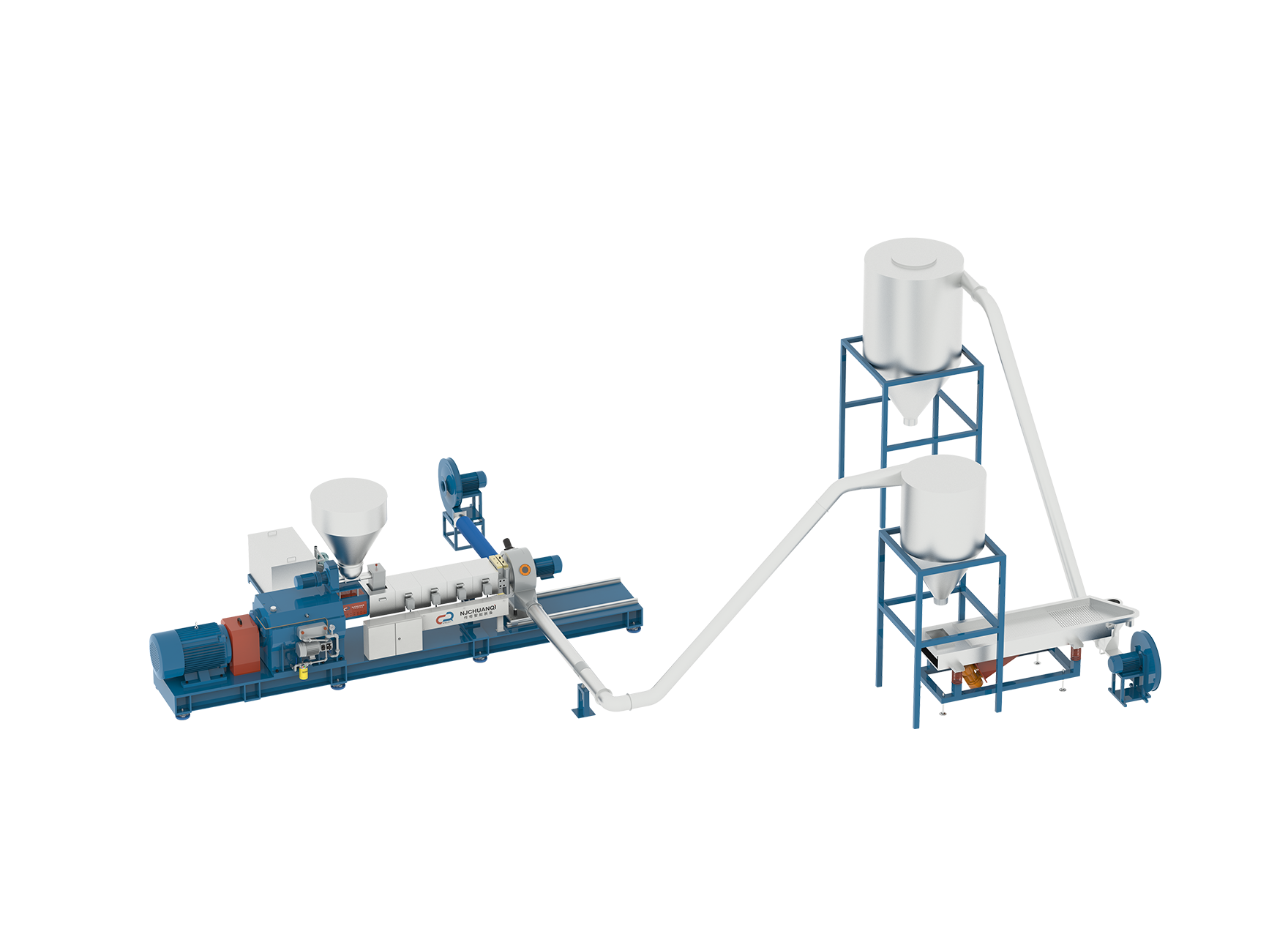

In contrast, the Plasticpreneur Extruder, designed for smaller-scale and community-based recycling projects, uses considerably less energy. Its lower power requirements reduce overall carbon emissions, making it more suitable for sustainable initiatives, particularly in areas with limited energy resources or where renewable energy is utilized.

Material Waste and Recycling Benefits

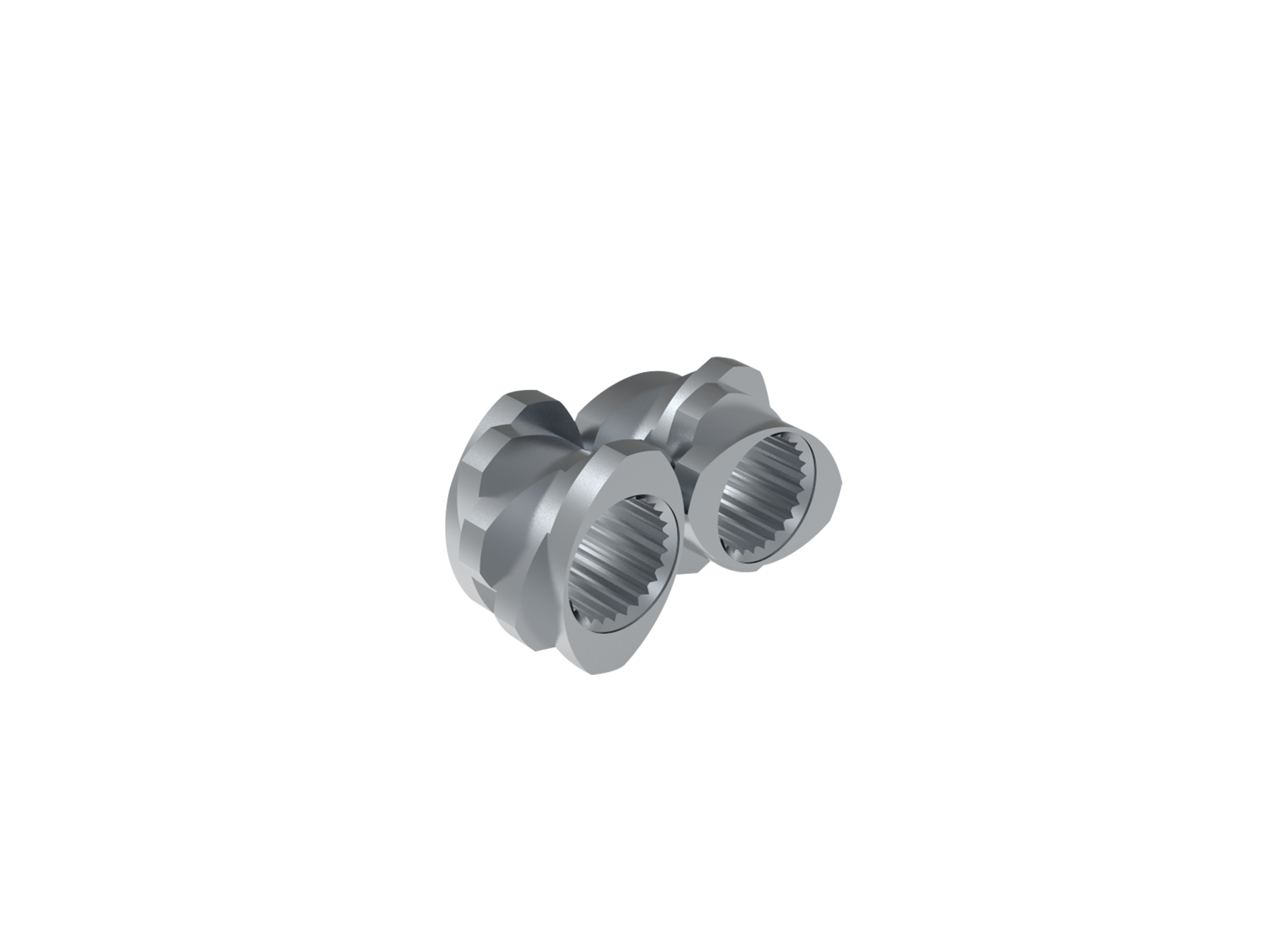

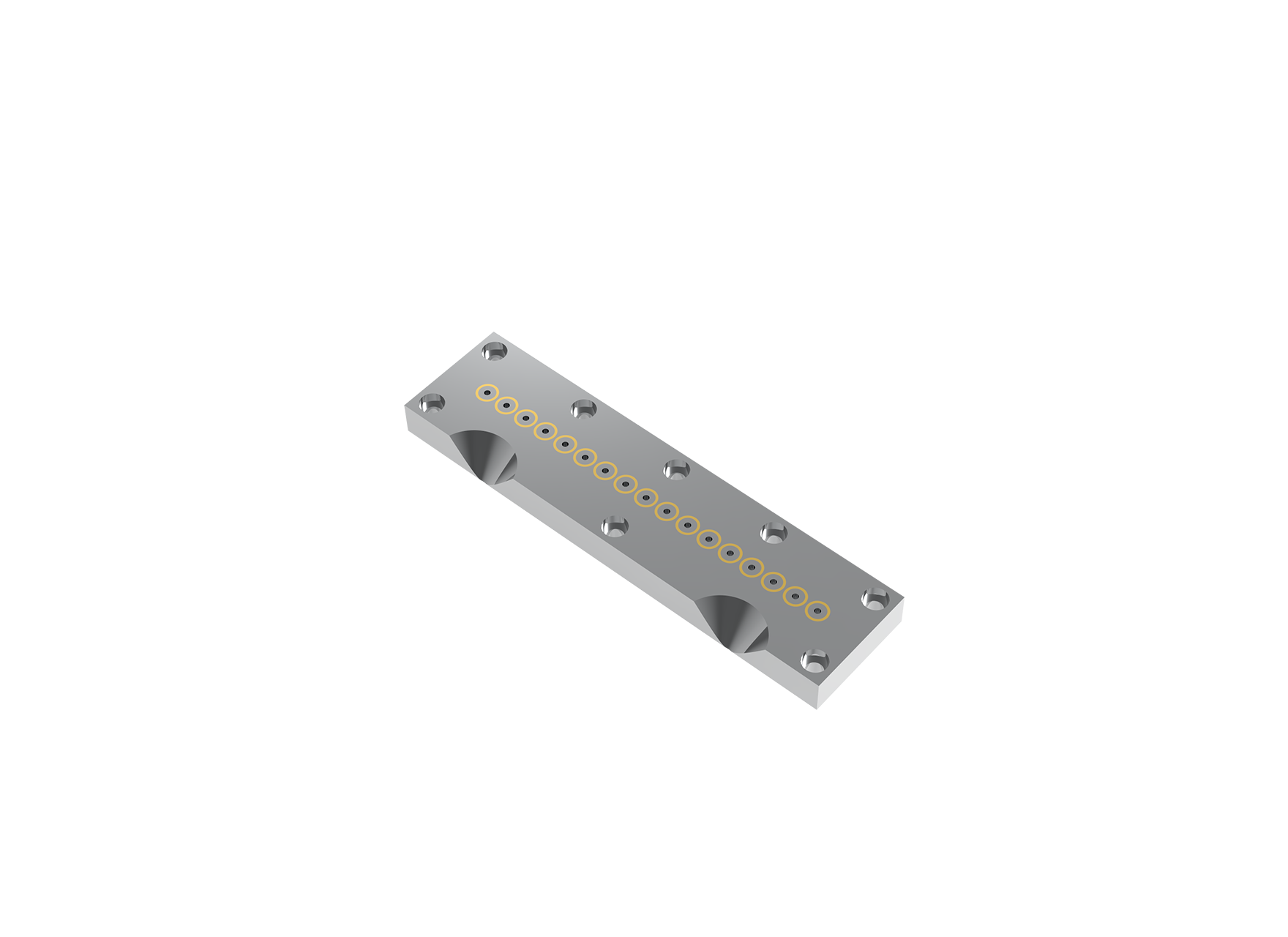

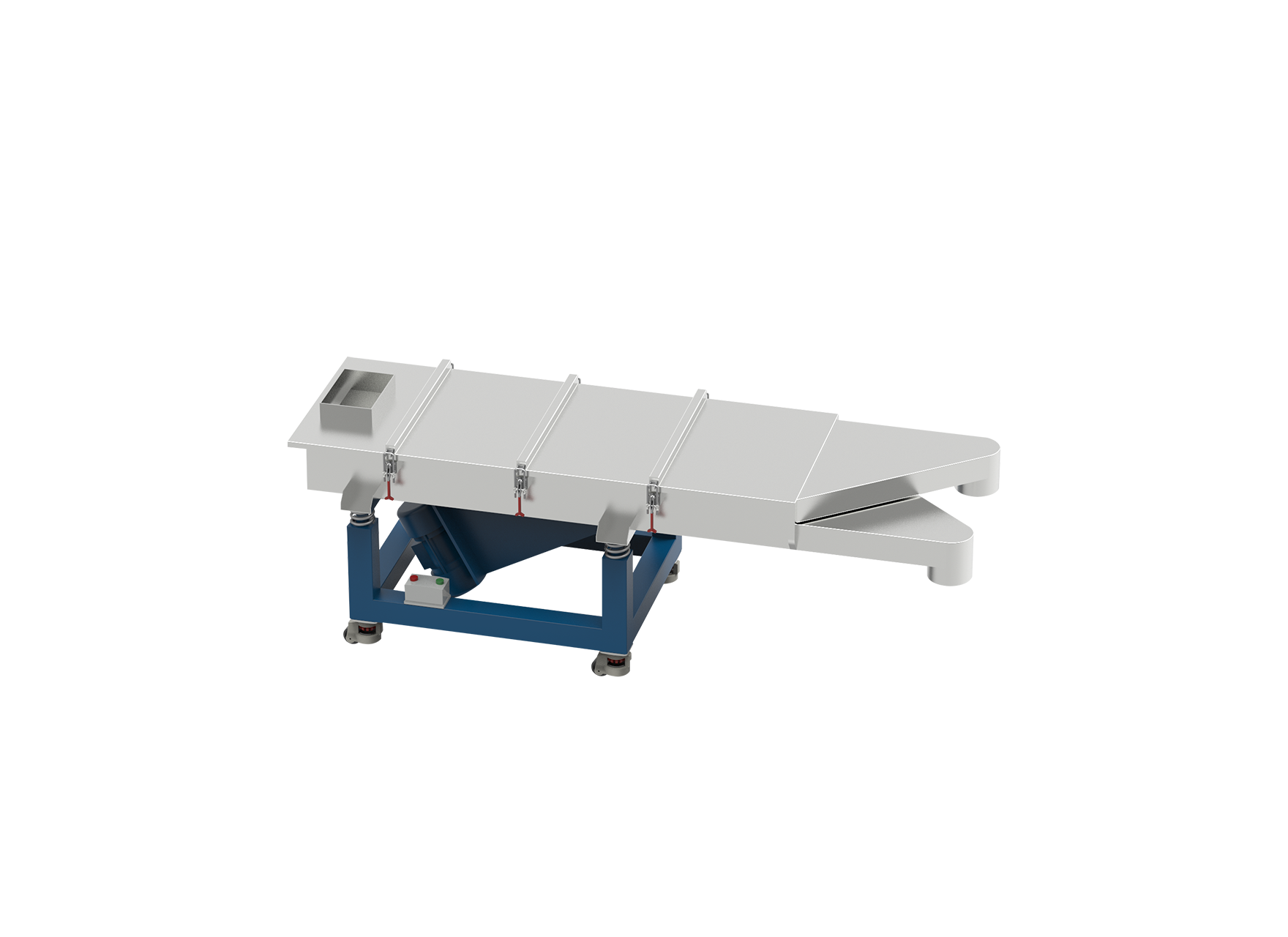

Waste generation during extrusion can harm the environment if not properly managed. Industrial machines often feature advanced controls to decrease scrap and ensure consistent product quality. This reduces material waste and promotes efficient resource use.

Plasticpreneur Extruders support localized recycling efforts by transforming post-consumer and post-industrial plastics into usable pellets or new products. This decentralization encourages circular economy principles, reducing plastic pollution and dependence on virgin materials. However, small-scale operations might face challenges such as variable feedstock quality, which can cause increased rejects and waste if not carefully managed.

Emissions and Air Quality Concerns

Heating plastic materials during extrusion can release volatile organic compounds (VOCs) and other pollutants. Larger polymer extrusion machines are frequently equipped with filtration and ventilation systems to reduce emissions, protecting both the environment and worker health.

Smaller extruders may lack comprehensive emission controls, potentially causing localized air quality issues if ventilation is inadequate. Proper training and safety measures are crucial for operators to reduce risks, especially in community settings.

Noise and Workplace Environment

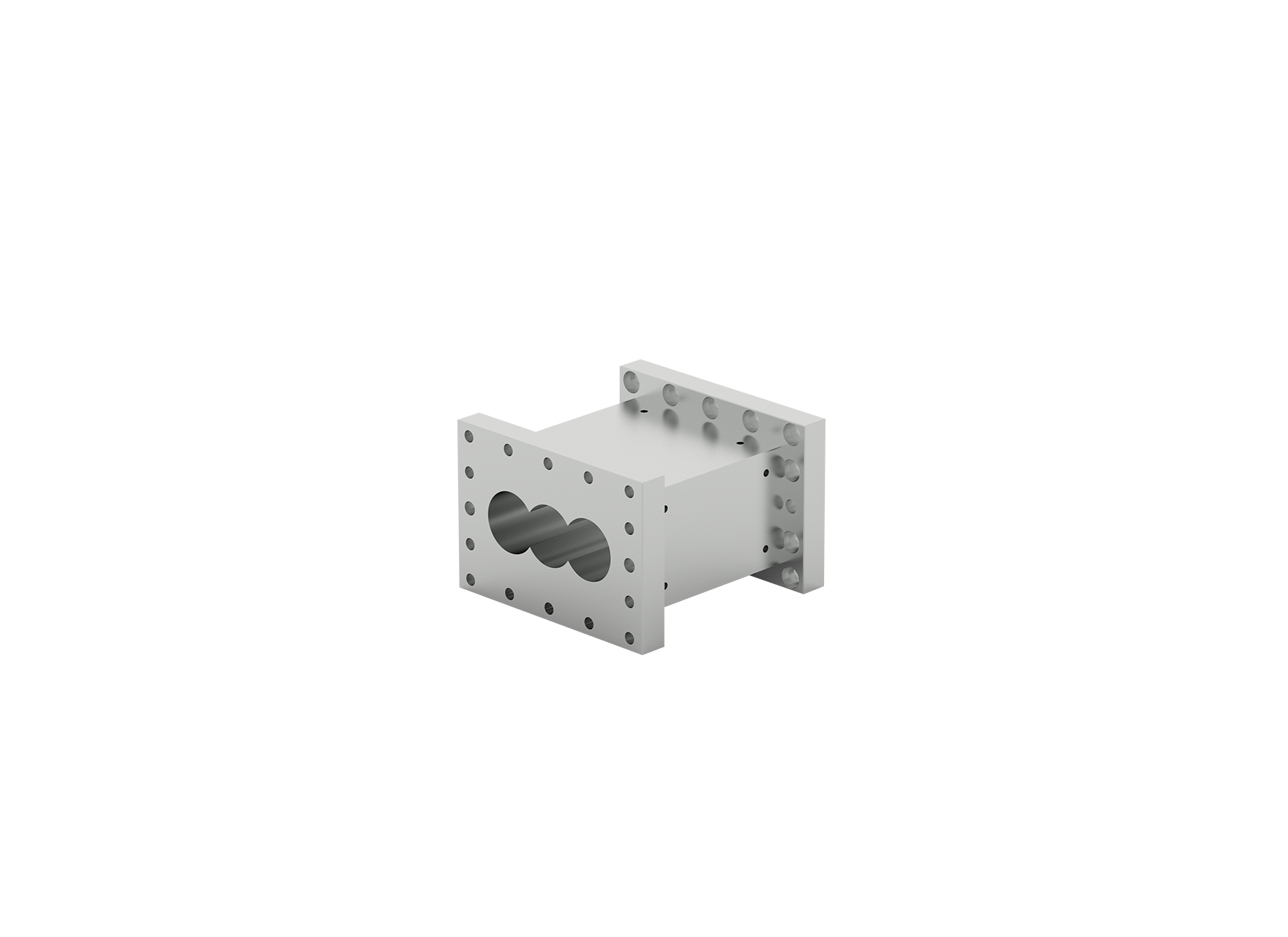

Noise pollution is another environmental factor associated with extrusion machines. High-capacity polymer extruders often generate more noise due to larger motors and complex mechanisms, requiring soundproofing measures to mitigate impact on surrounding environments.

Plasticpreneur units tend to operate more quietly, making them more suitable for use in residential or small community spaces where noise restrictions may apply.

Water and Chemical Usage

Water use for cooling and cleaning in extrusion processes also influences environmental sustainability. Industrial setups commonly utilize closed-loop systems to conserve water and prevent contamination.

Small-scale extruders may rely on simpler water systems, which require careful monitoring to avoid excessive consumption or pollution. Additionally, handling of cleaning chemicals must follow environmental safety standards in both types of operations to prevent harmful runoff.

Conclusion

Both the Polymer Extruder Machine and the Plasticpreneur Extruder affect the environment through energy consumption, emissions, waste, noise, and resource use. Industrial polymer extruders benefit from advanced technology to reduce waste and emissions, but have higher energy demands. Plasticpreneur extruders promote grassroots recycling and lower energy consumption but require diligent management to maintain air quality and reduce waste.

Selecting the right extrusion equipment depends on balancing production needs with environmental considerations. By integrating efficient technologies and responsible practices, users can reduce negative impacts and contribute to a more sustainable plastic industry.

English

English 中文简体

中文简体 русский

русский عربى

عربى +86-189 1339 2785

+86-189 1339 2785