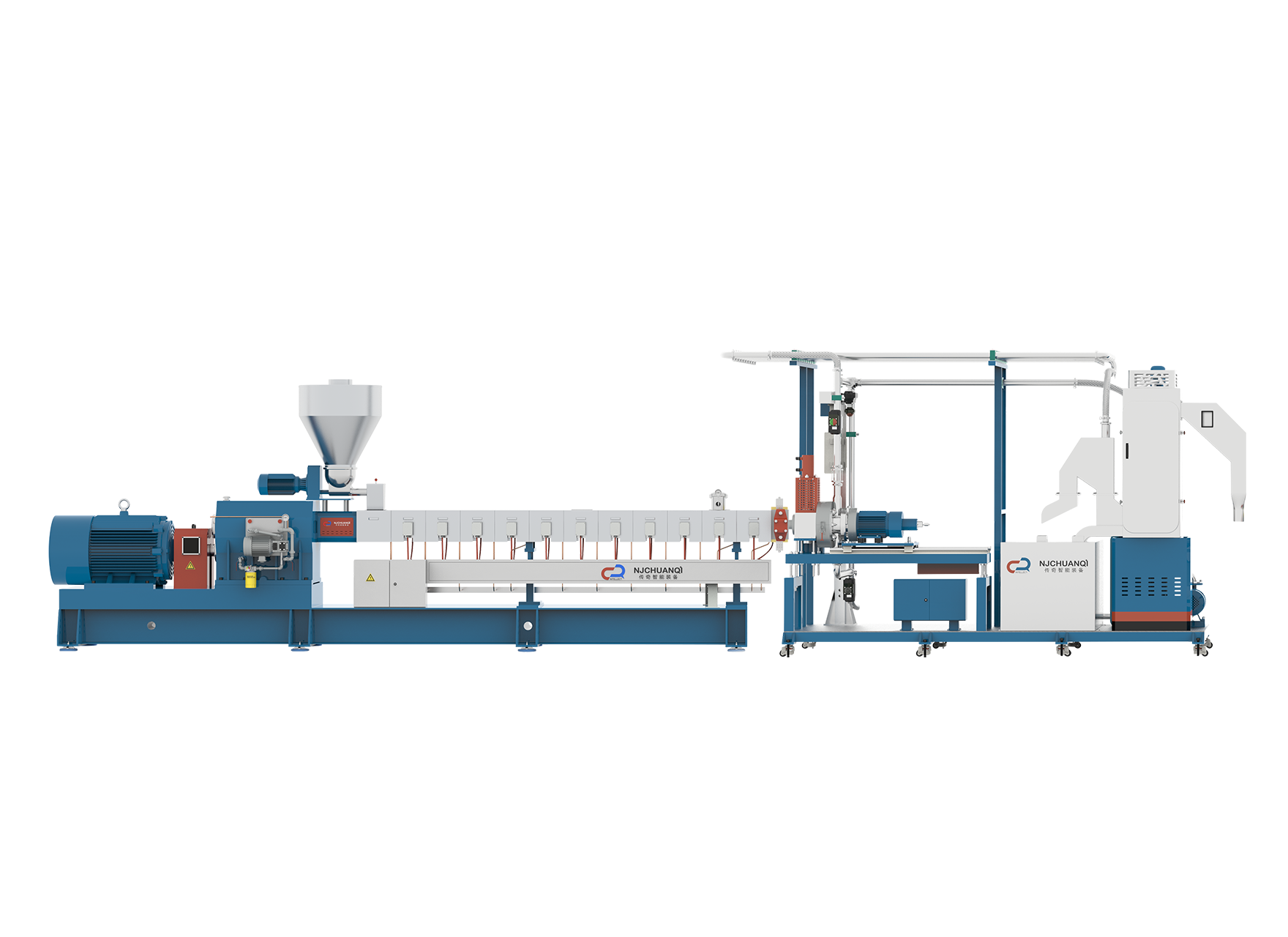

Design Heavy Duty Pellet Granulator Manufacturing Company

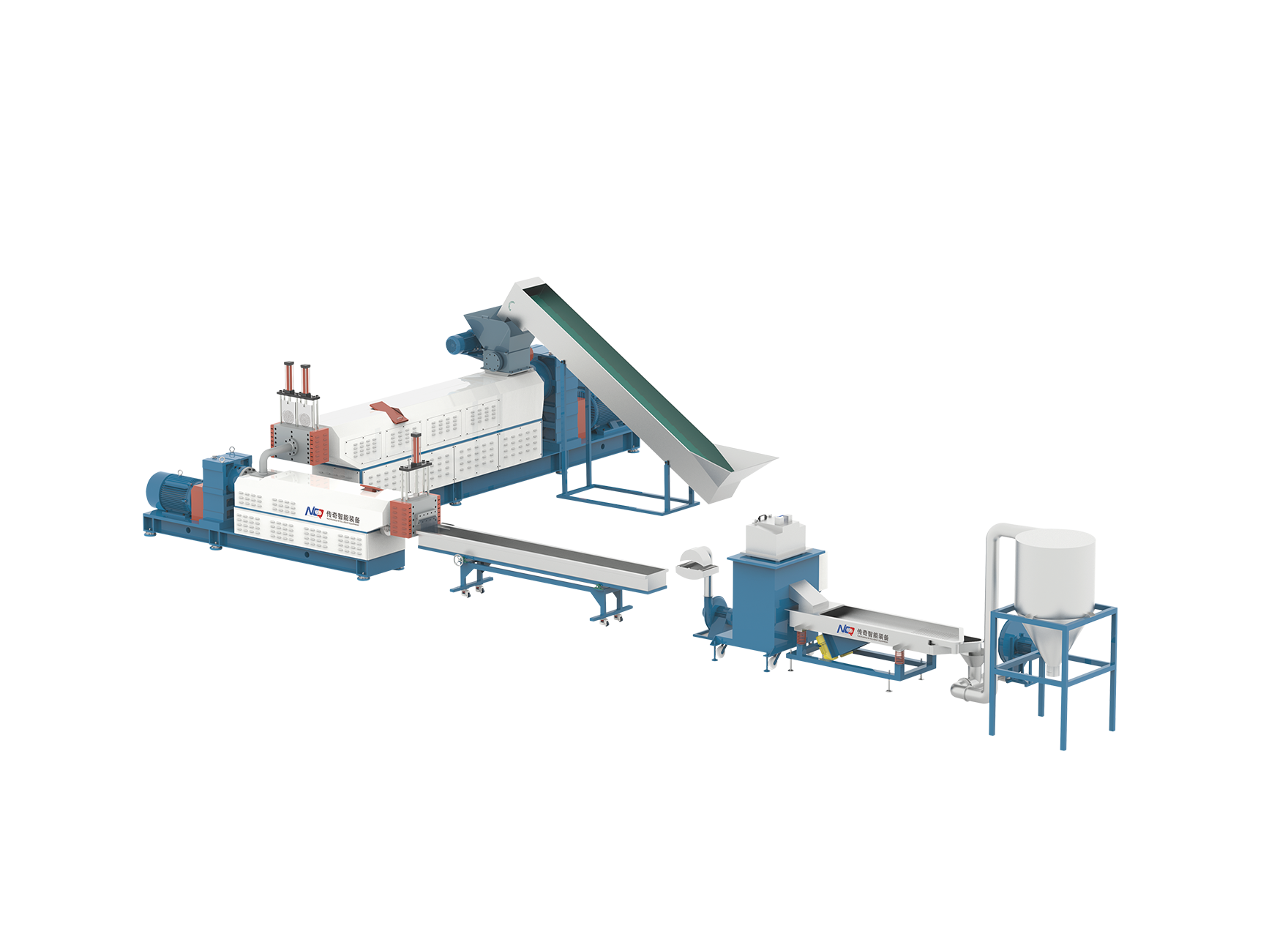

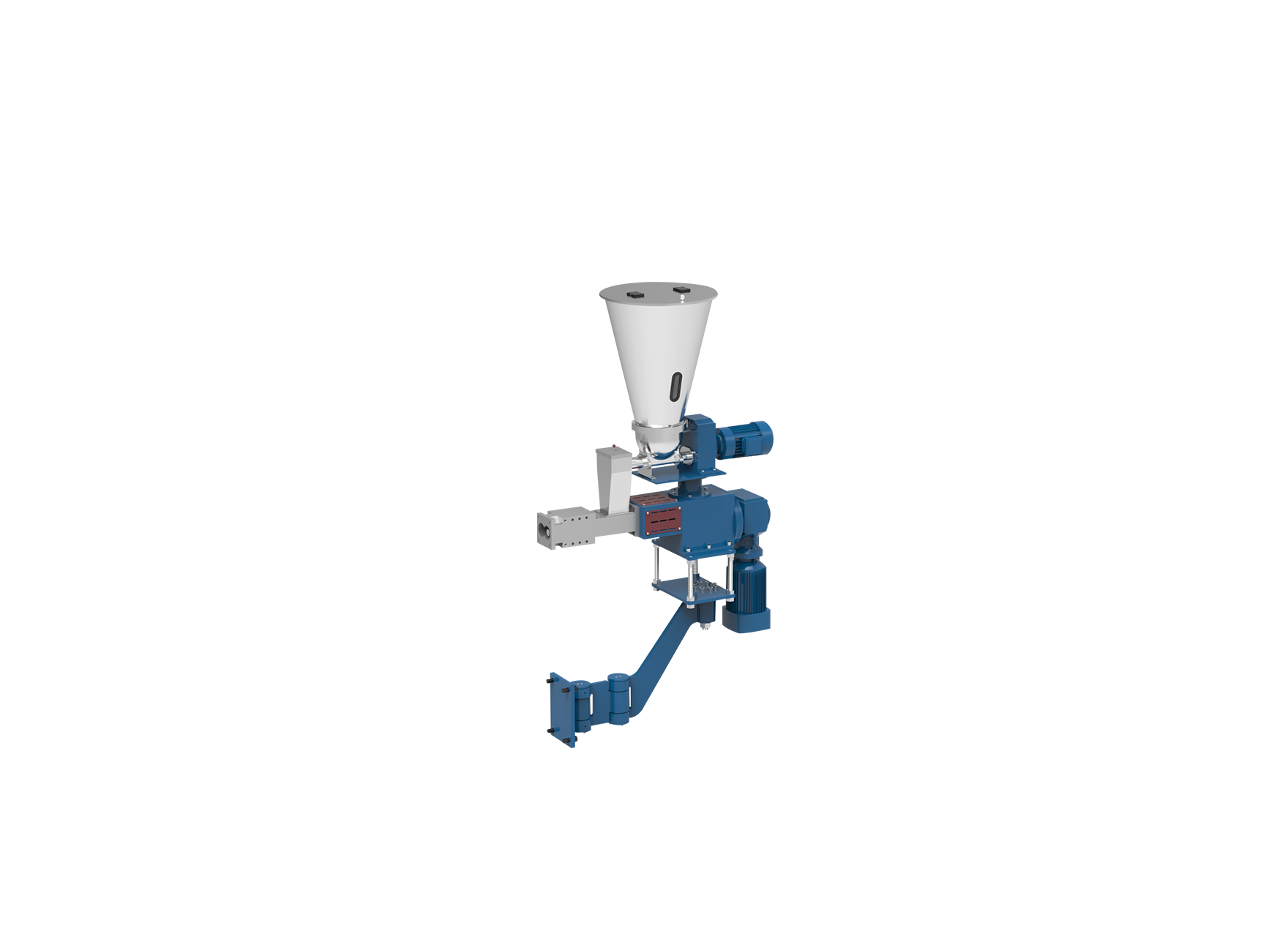

In the realm of material processing, the ability to control particle size with precision is a critical factor that influences the quality and consistency of end products. Pellet Granulator and Heavy Duty Granulator are two types of machinery that play a pivotal role in this regard. These machines are designed to break down larger materials into smaller, uniform pellets or granules, and their effectiveness in achieving precise particle size control is paramount.

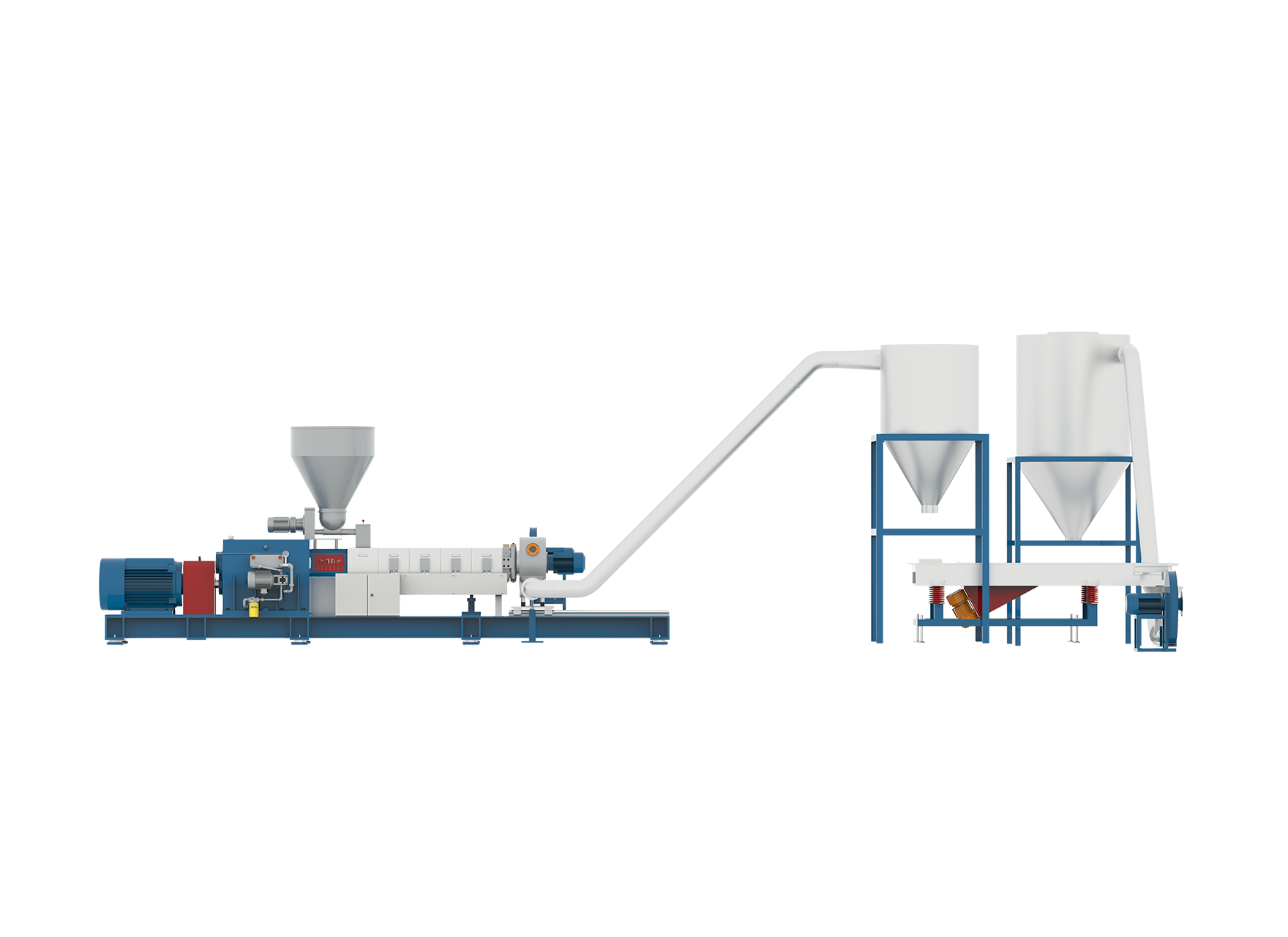

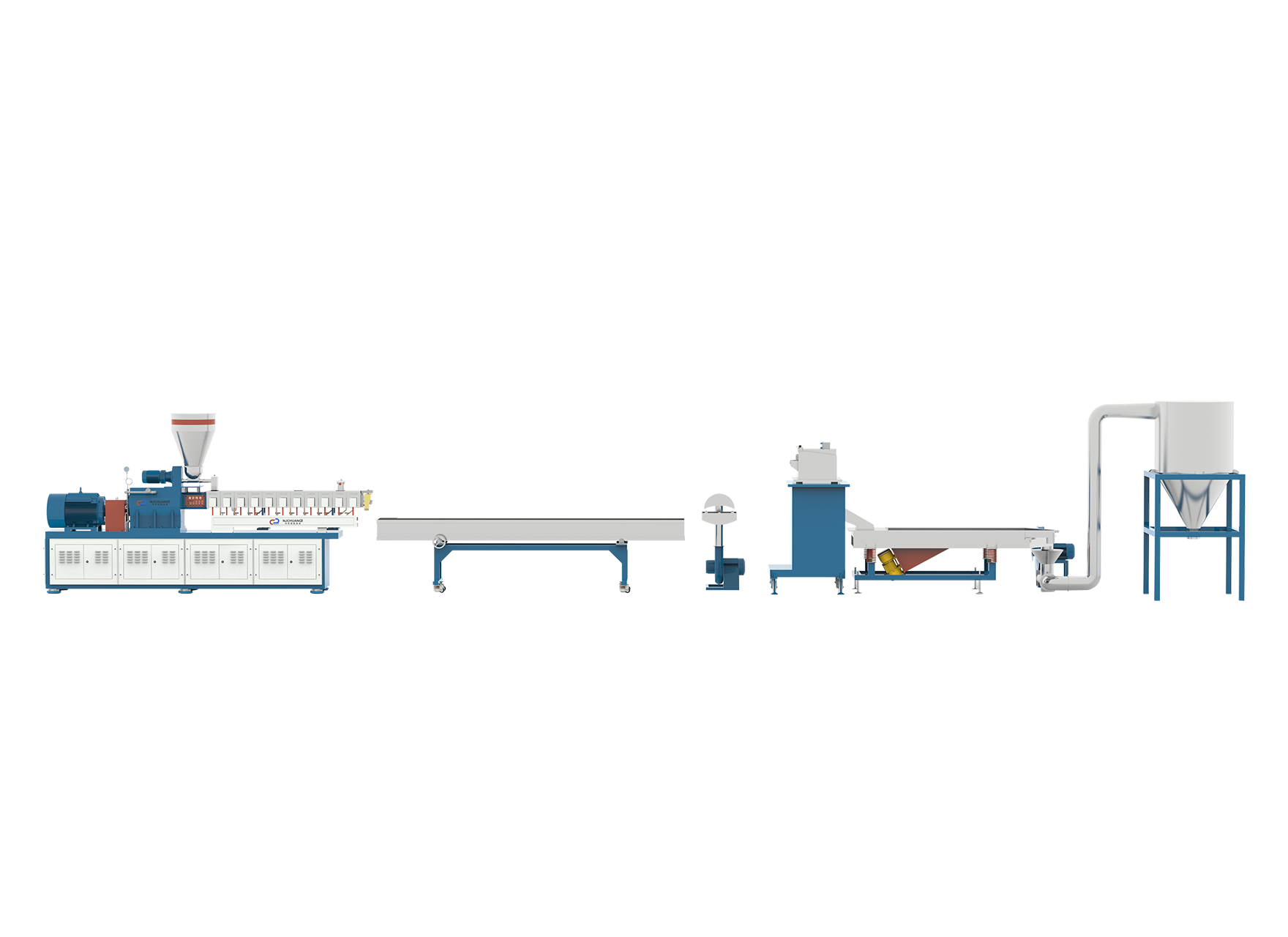

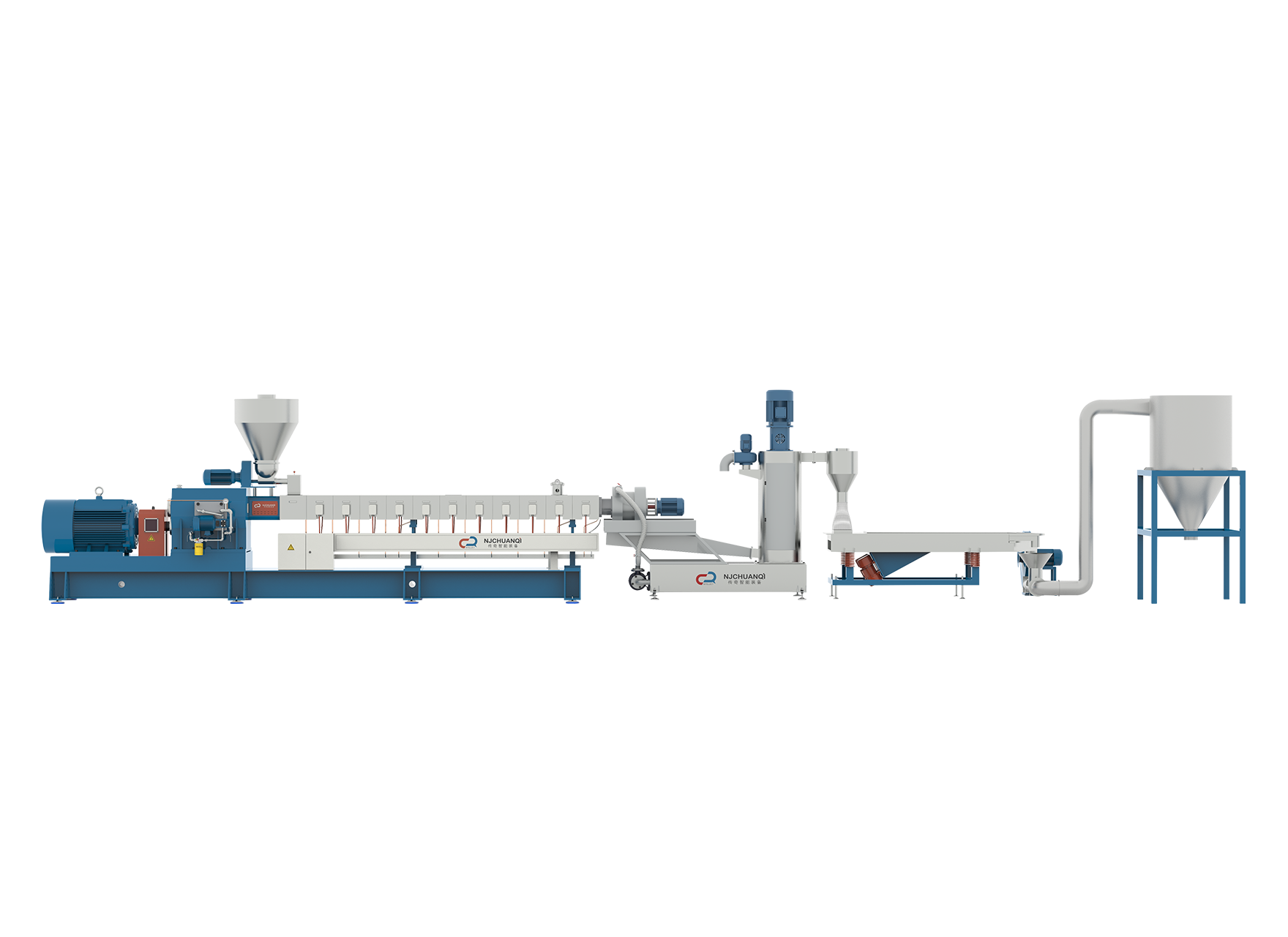

The Pellet Granulator is specifically engineered for the processing of plastics, rubber, and other polymers into uniform pellets. It is widely used in recycling industries where the goal is to transform waste materials into reusable pellets. The machine's precision in particle size control is achieved through a combination of advanced cutting technology and meticulous machine settings. The blades within the Pellet Granulator are designed to shear the material at a controlled rate, ensuring that the resulting pellets are of consistent size and shape. This uniformity is crucial for the subsequent processing steps, such as extrusion or injection molding, where the quality of the final product is directly related to the uniformity of the input material.

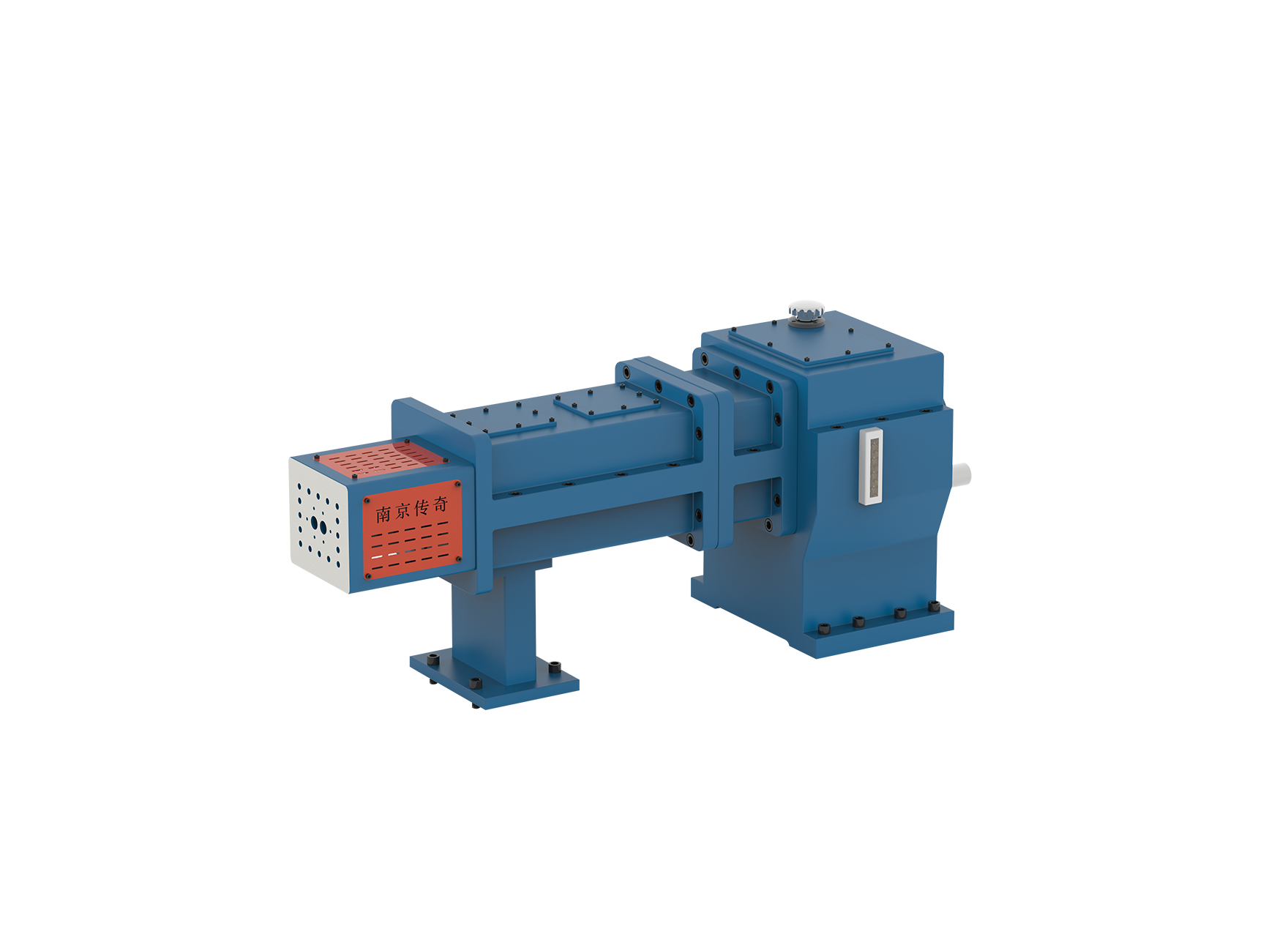

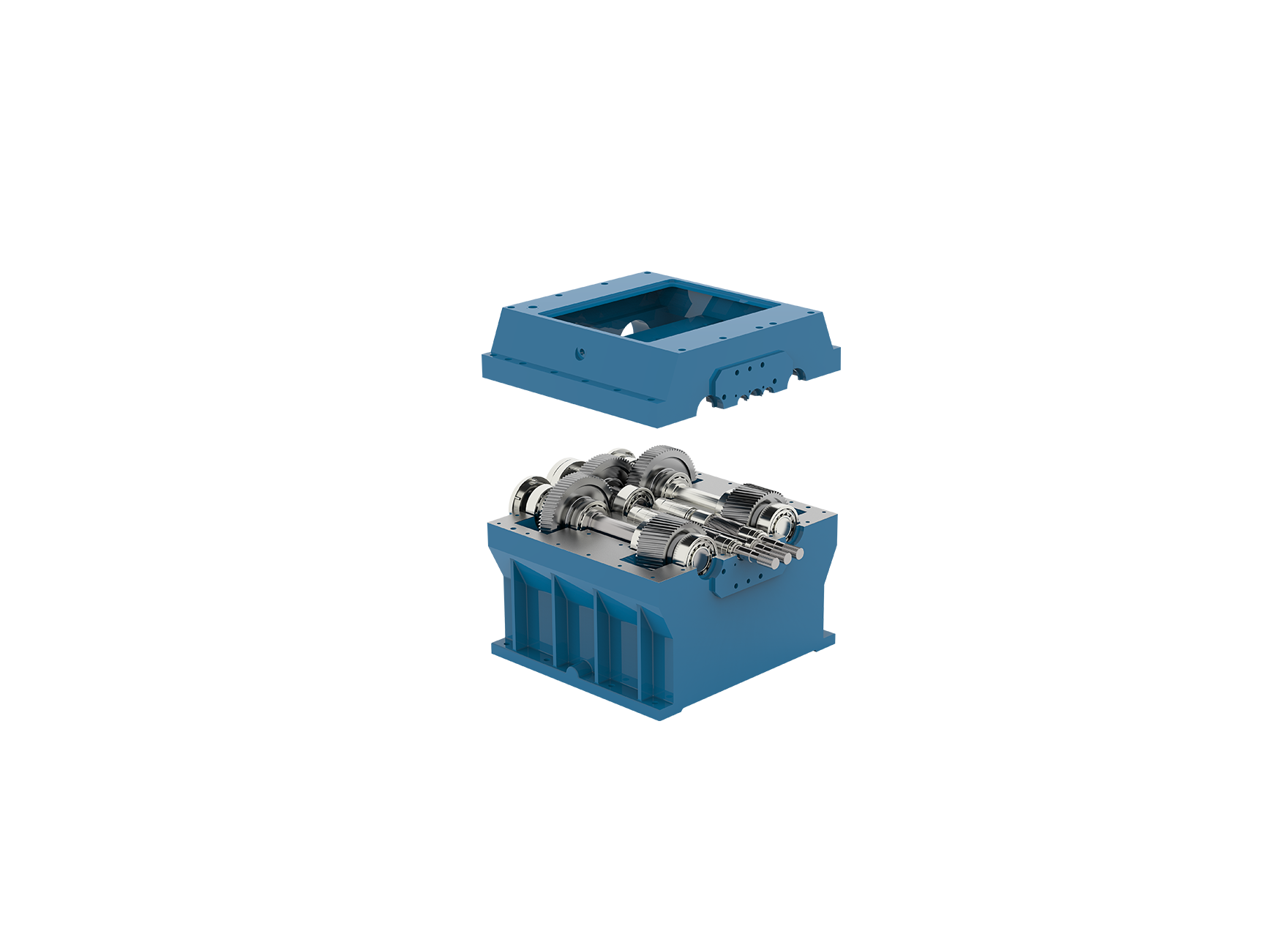

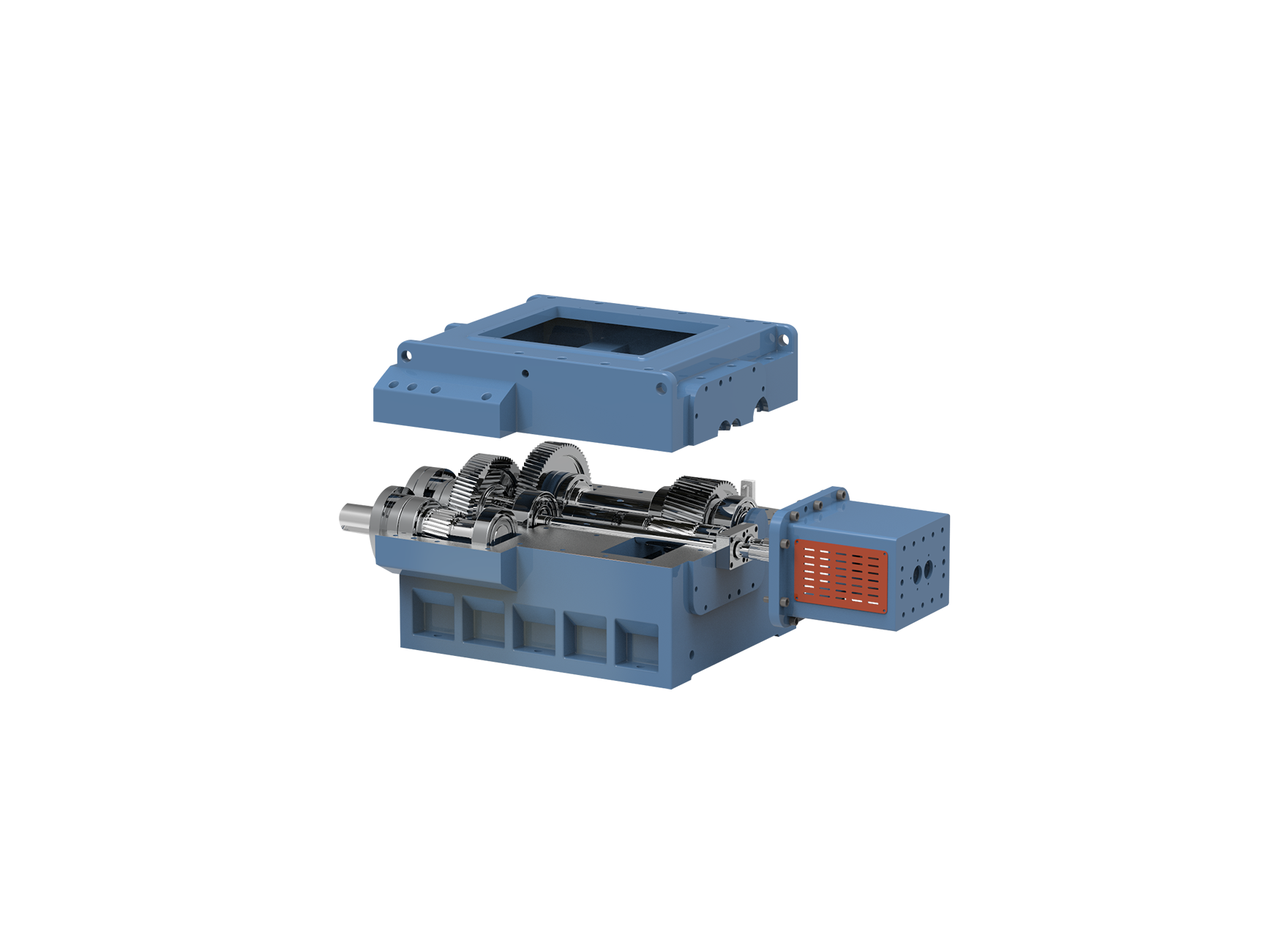

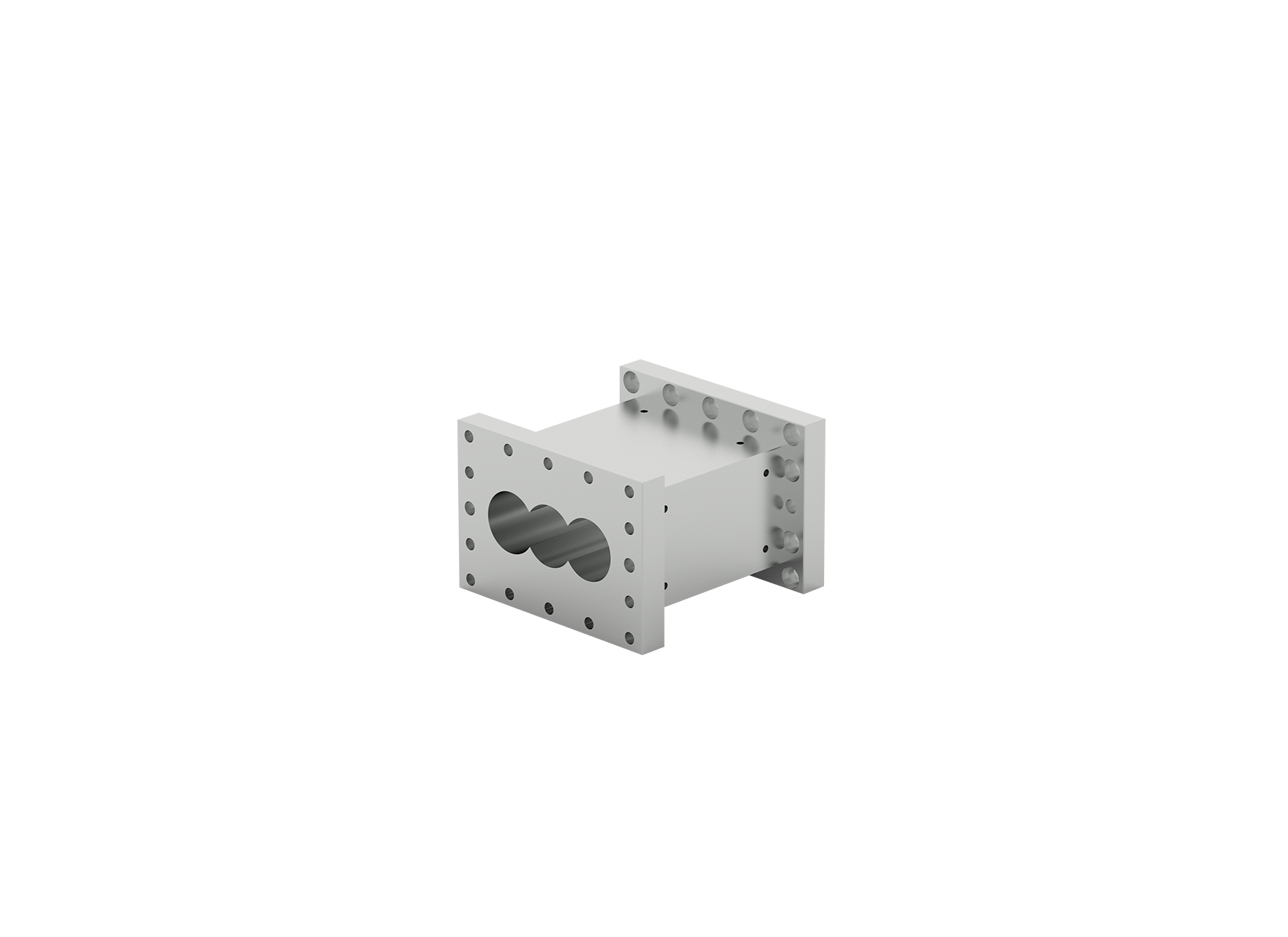

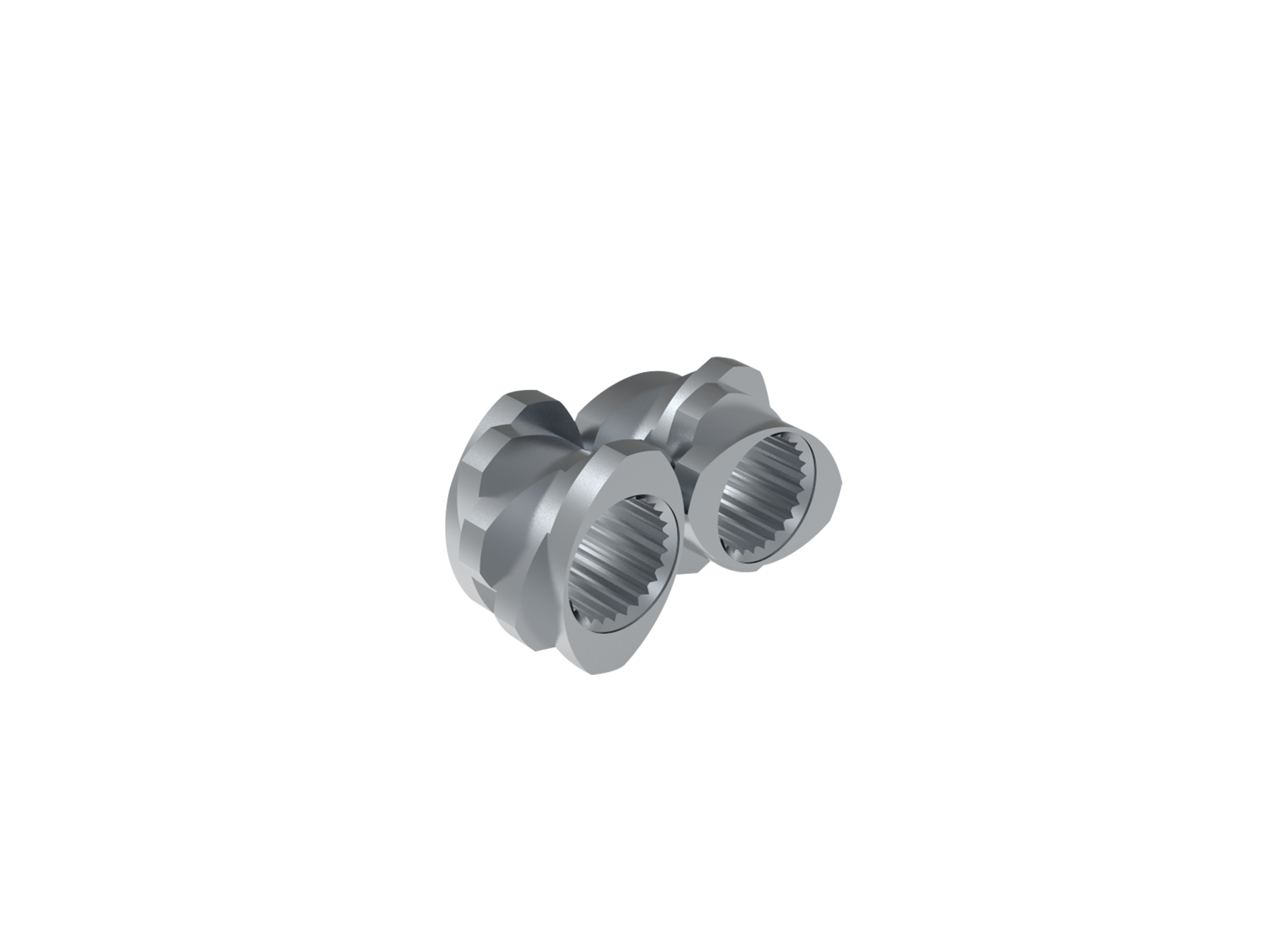

On the other hand, the Heavy Duty Granulator is built to handle tougher tasks, such as the granulation of metals, heavy plastics, and other dense materials. These granulators are designed to withstand the rigors of heavy-duty processing, where high torque and robust construction are necessary. The precision in particle size control for Heavy Duty Granulators is achieved through the use of robust cutting systems and adjustable knives. These knives can be set at specific angles and positions to control the size of the granules produced. Additionally, the speed of the cutting mechanism can be adjusted to fine-tune the particle size, allowing for a high degree of control over the final product.

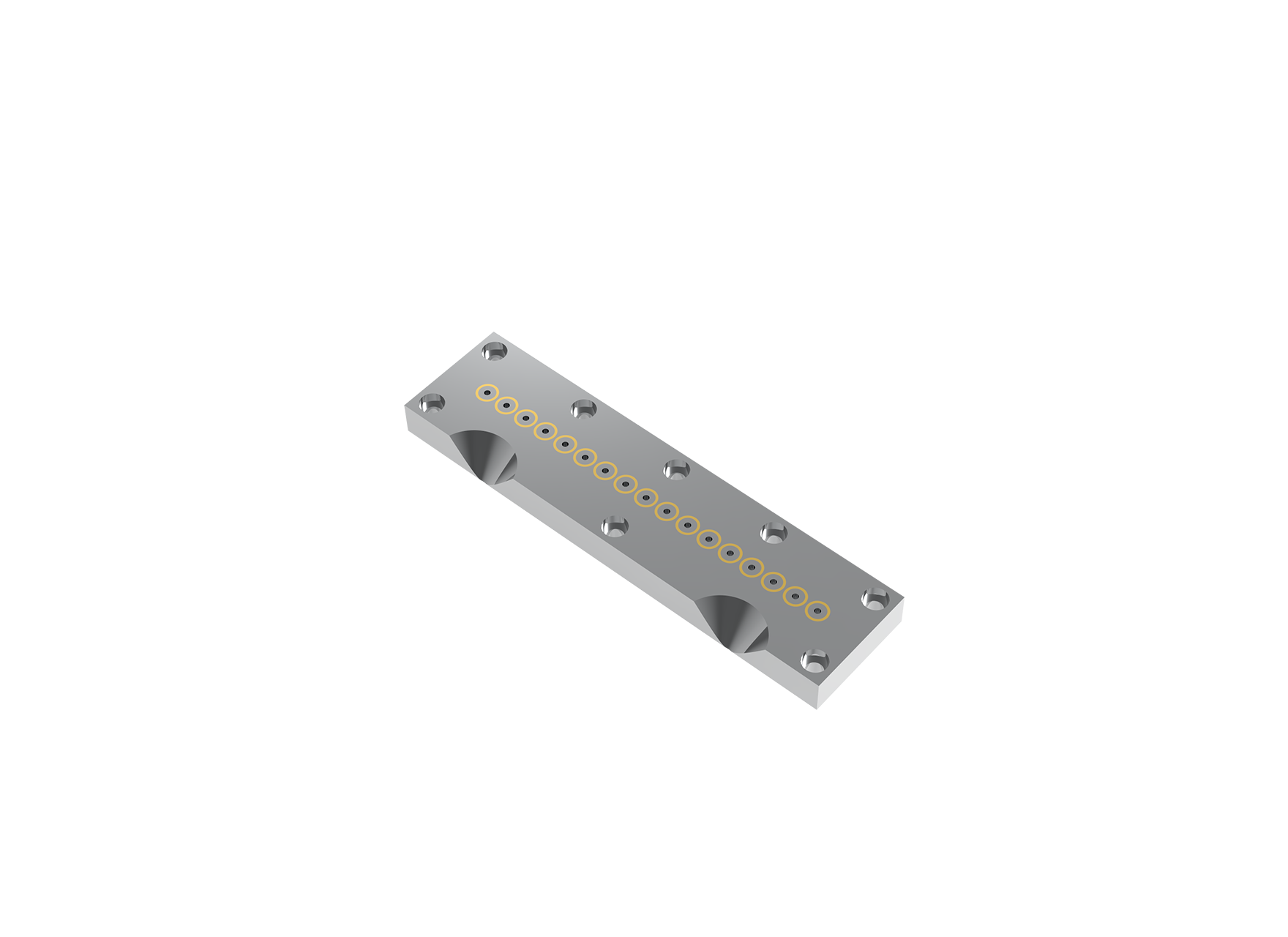

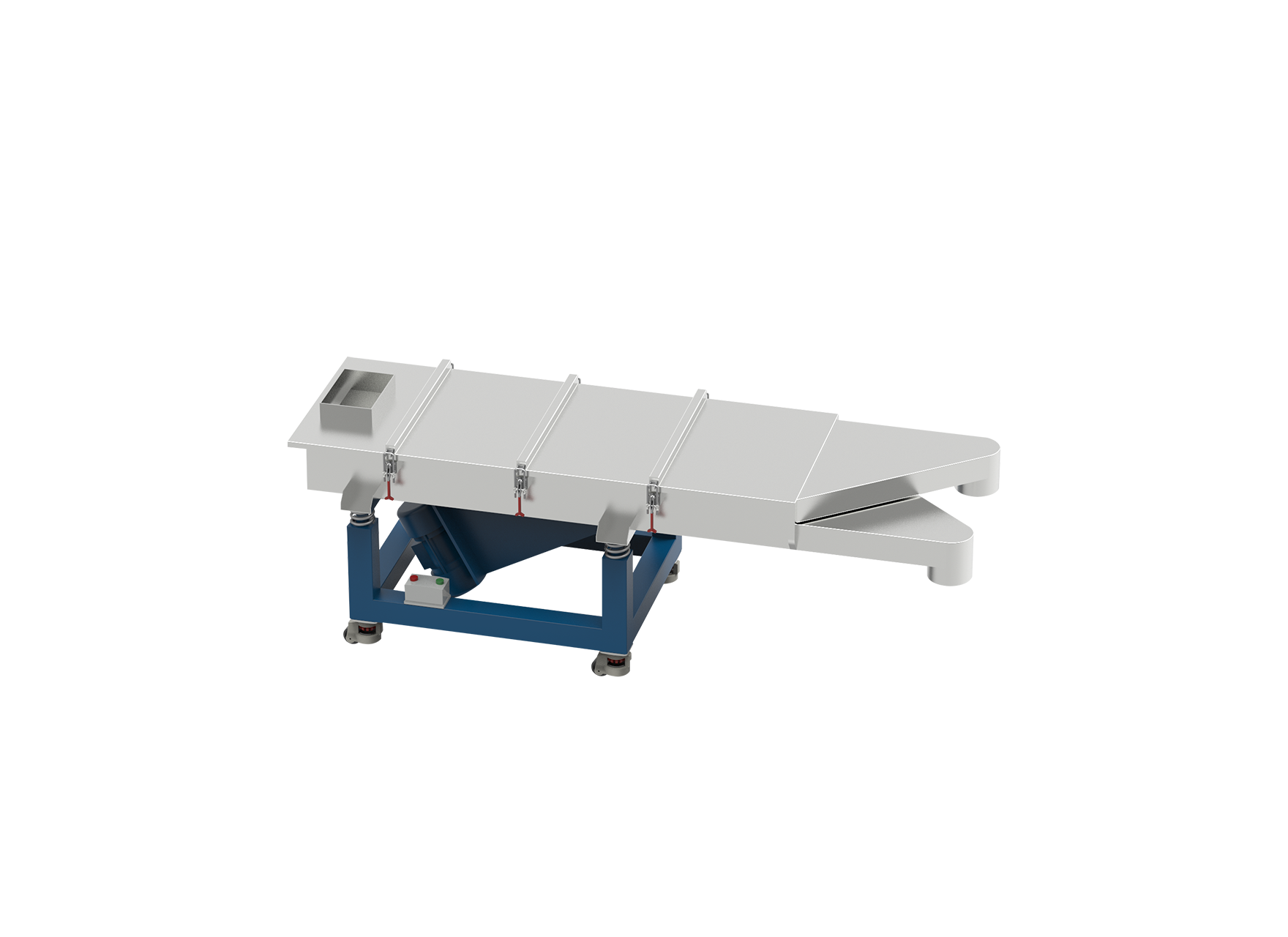

Both the Pellet Granulator and the Heavy Duty Granulator rely on a system of screens or sieves to further refine the particle size. These screens can be easily replaced or adjusted to achieve the desired pellet or granule size. The material is forced through the screen, and only the particles that meet the size criteria pass through, while larger pieces are recycled back into the granulator for further processing. This system ensures that the output is consistent and meets the specifications required for the application.

To enhance the precision of particle size control, both types of granulators can be equipped with sensors and feedback systems that monitor the process in real-time. These systems can automatically adjust the settings of the granulator based on the feedback received, ensuring that the particle size remains within the desired parameters. This level of automation not only improves the precision of the process but also increases the efficiency of the operation.

In conclusion, the Pellet Granulator and Heavy Duty Granulator are indispensable machines in the field of material processing. Their ability to achieve precise particle size control is a testament to the advanced engineering and design that goes into their construction. By utilizing technology, adjustable cutting mechanisms, and real-time monitoring systems, these granulators ensure that the end product is of high quality, meeting the strict standards required in various industries.

English

English 中文简体

中文简体 русский

русский عربى

عربى +86-189 1339 2785

+86-189 1339 2785