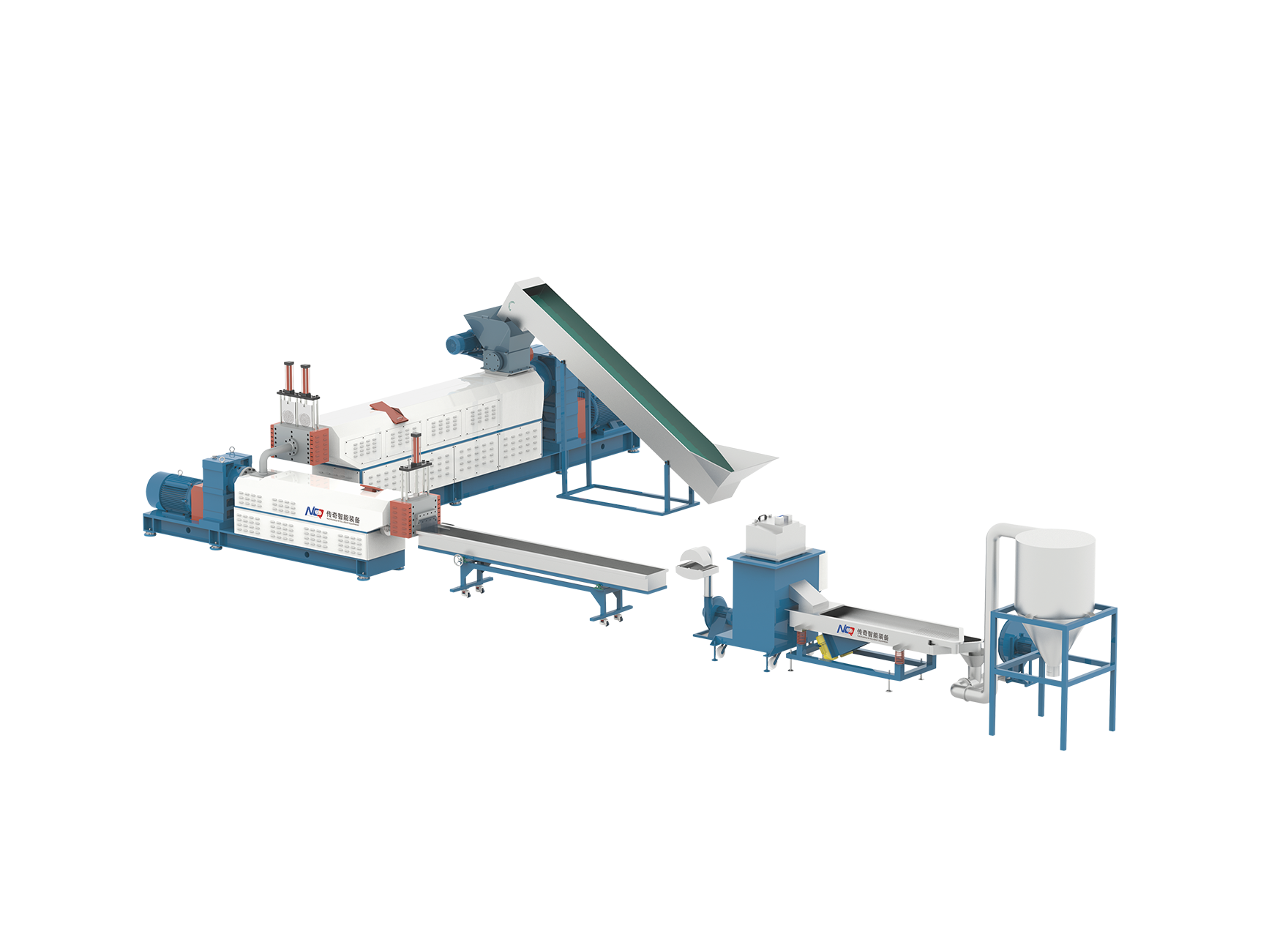

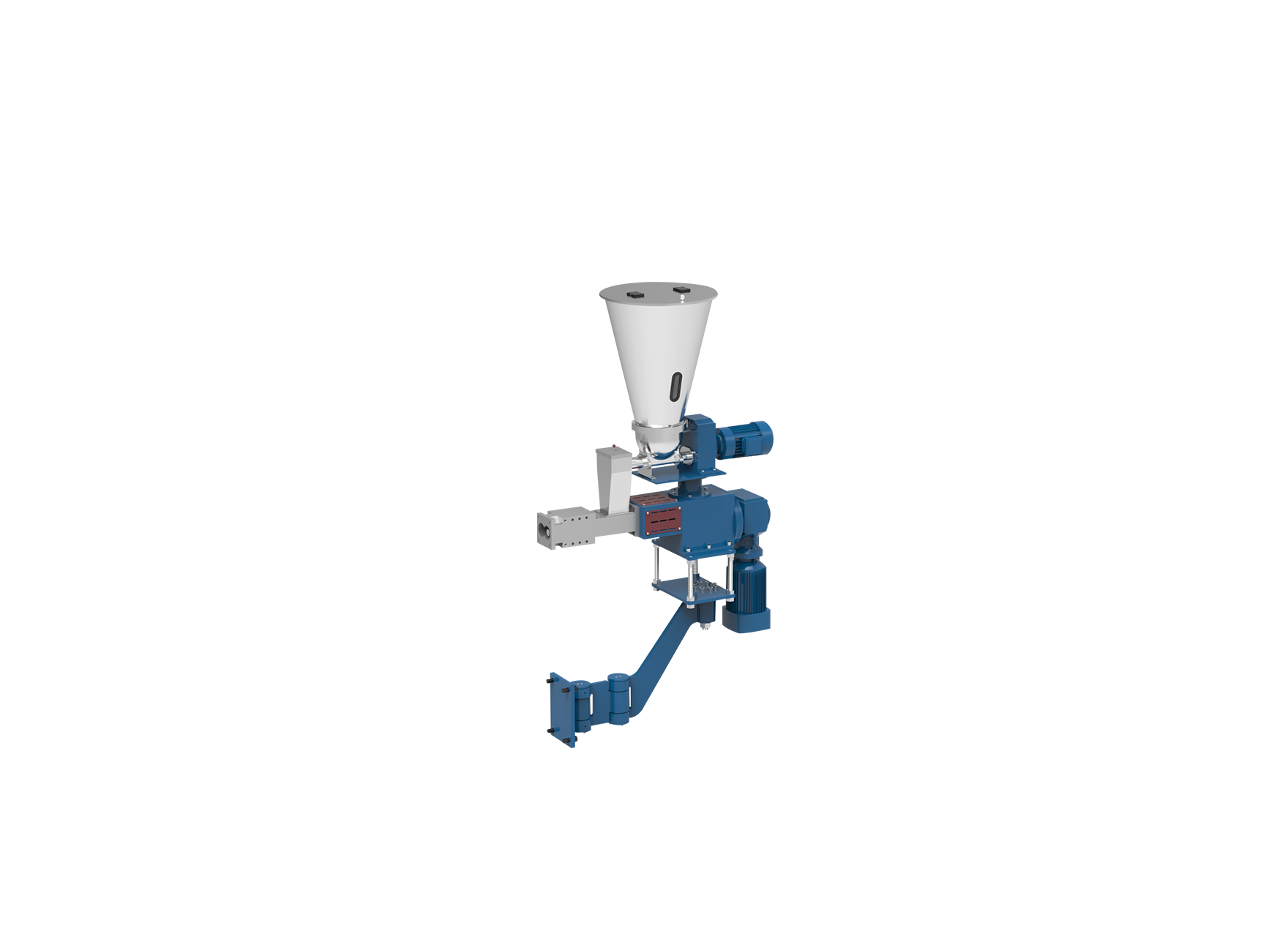

Achieving uniform pellet size is essential in many manufacturing processes to ensure product quality, ease of handling, and efficient downstream processing. Two common types of equipment used in pellet production are the Industrial Pelletizer Machine and the Water Ring Pelletizer. Although they operate differently, both technologies employ key mechanisms to maintain pellet uniformity. This article explores how each machine guarantees consistent pellet size and shape, contributing to reliable production outcomes.

Controlling Pellet Size in Industrial Pelletizer Machines

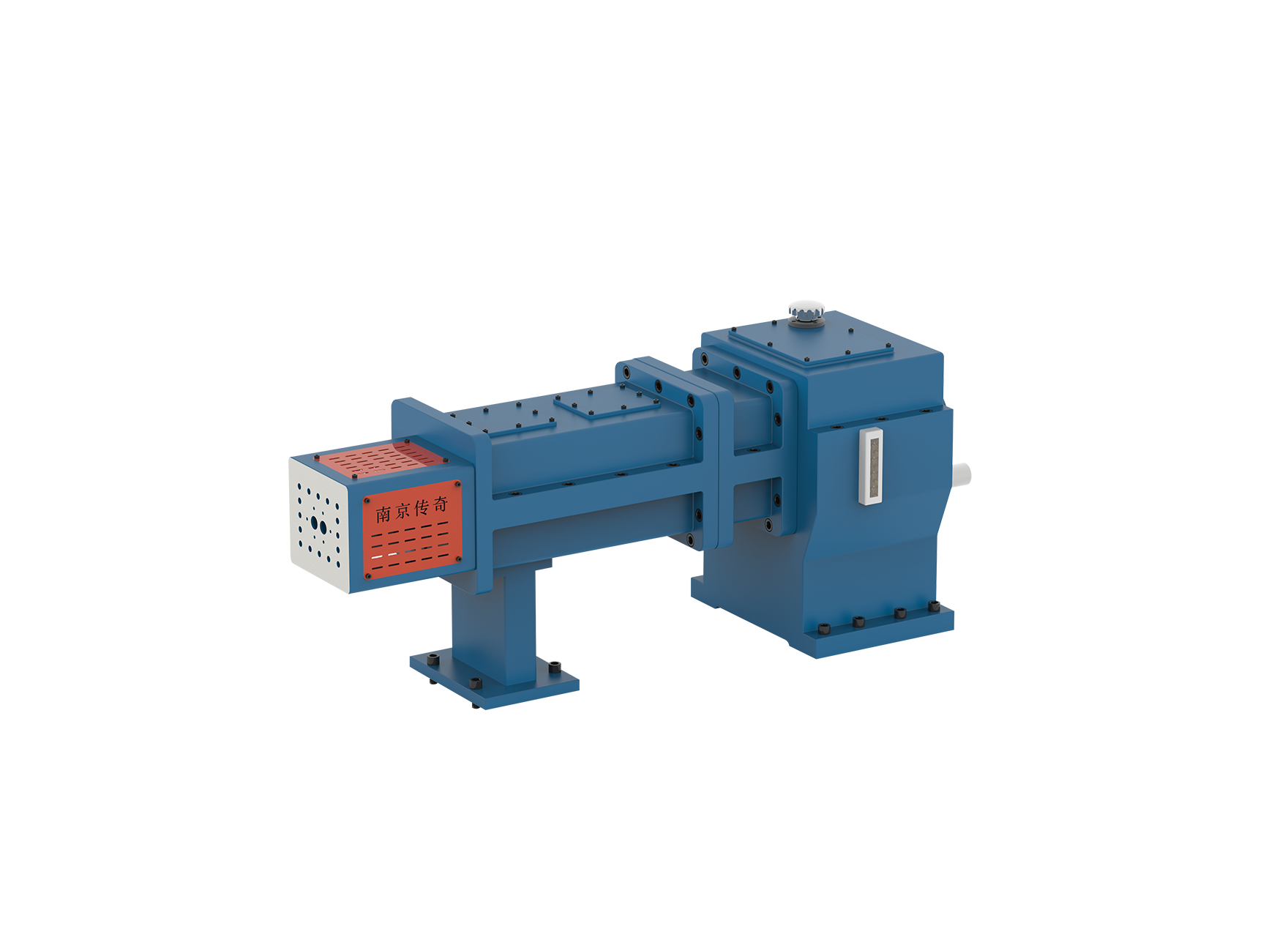

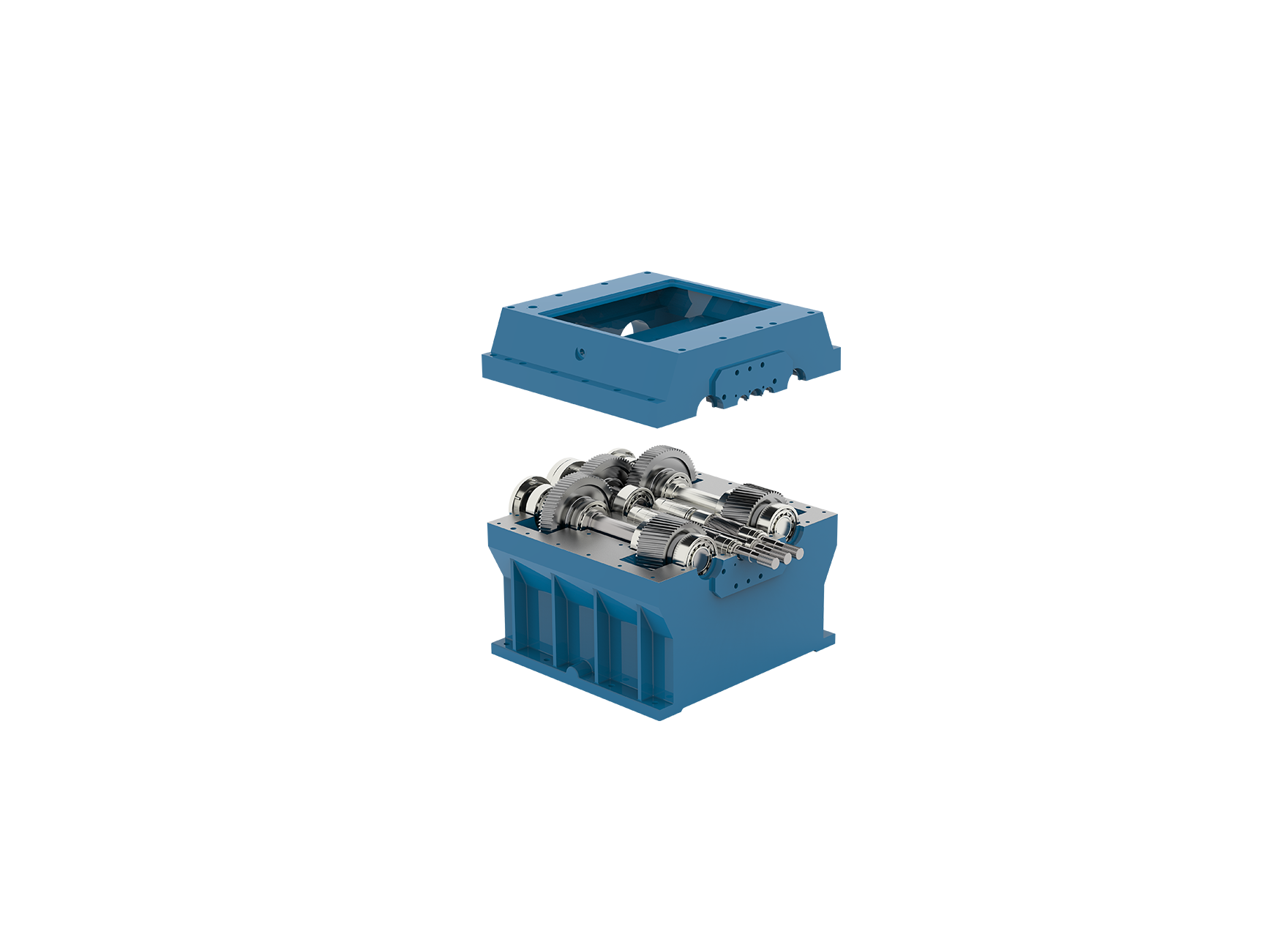

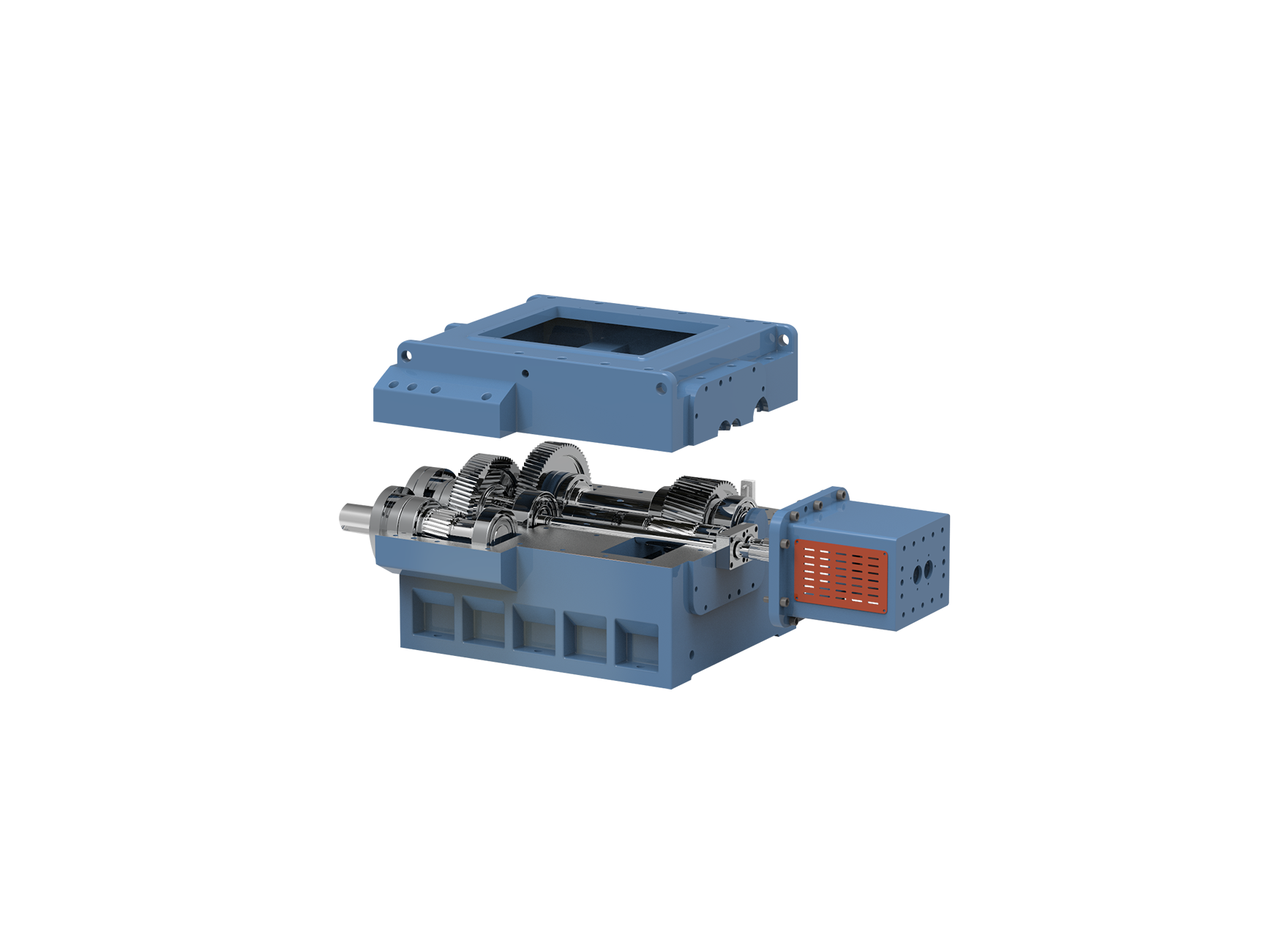

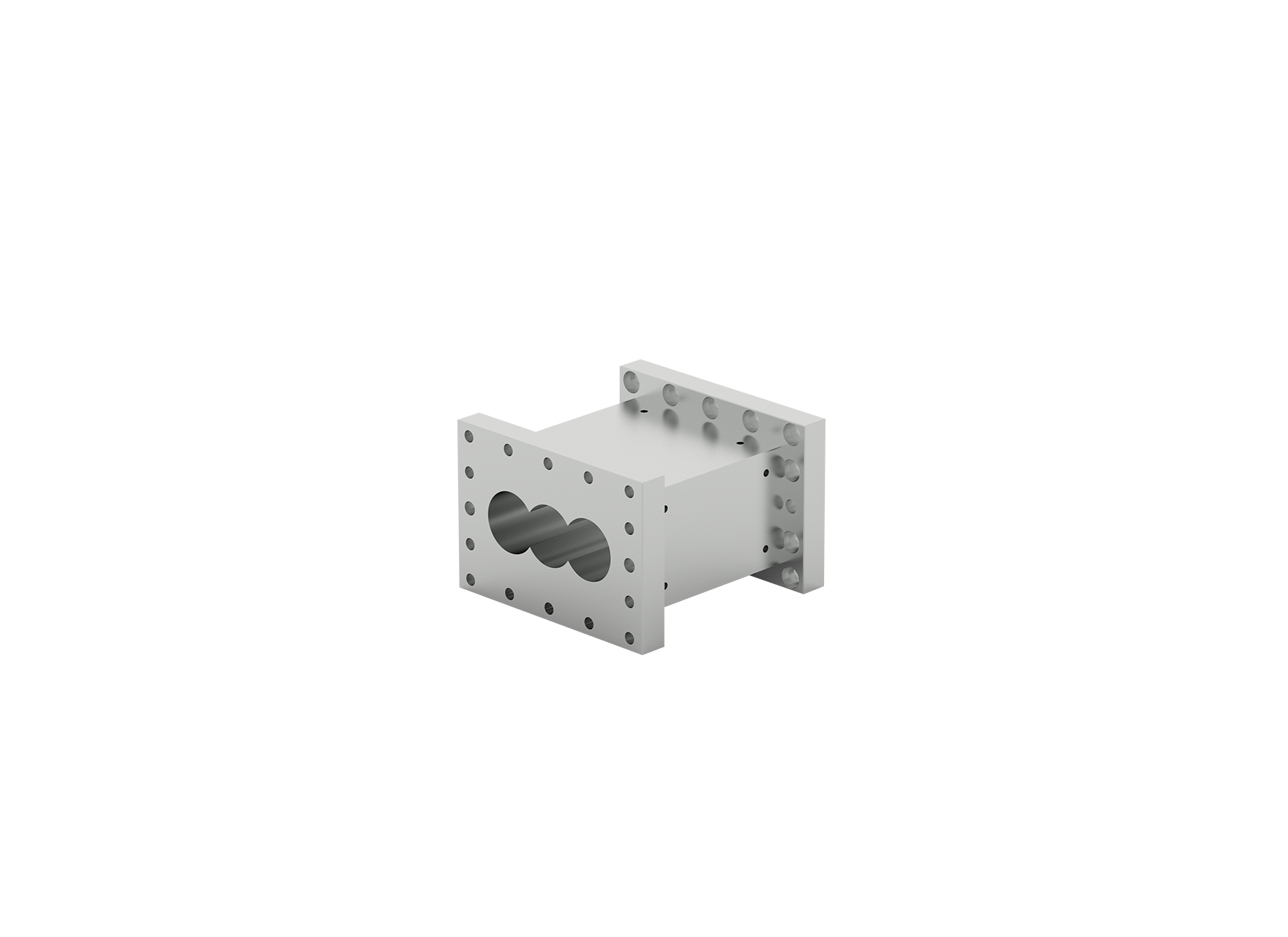

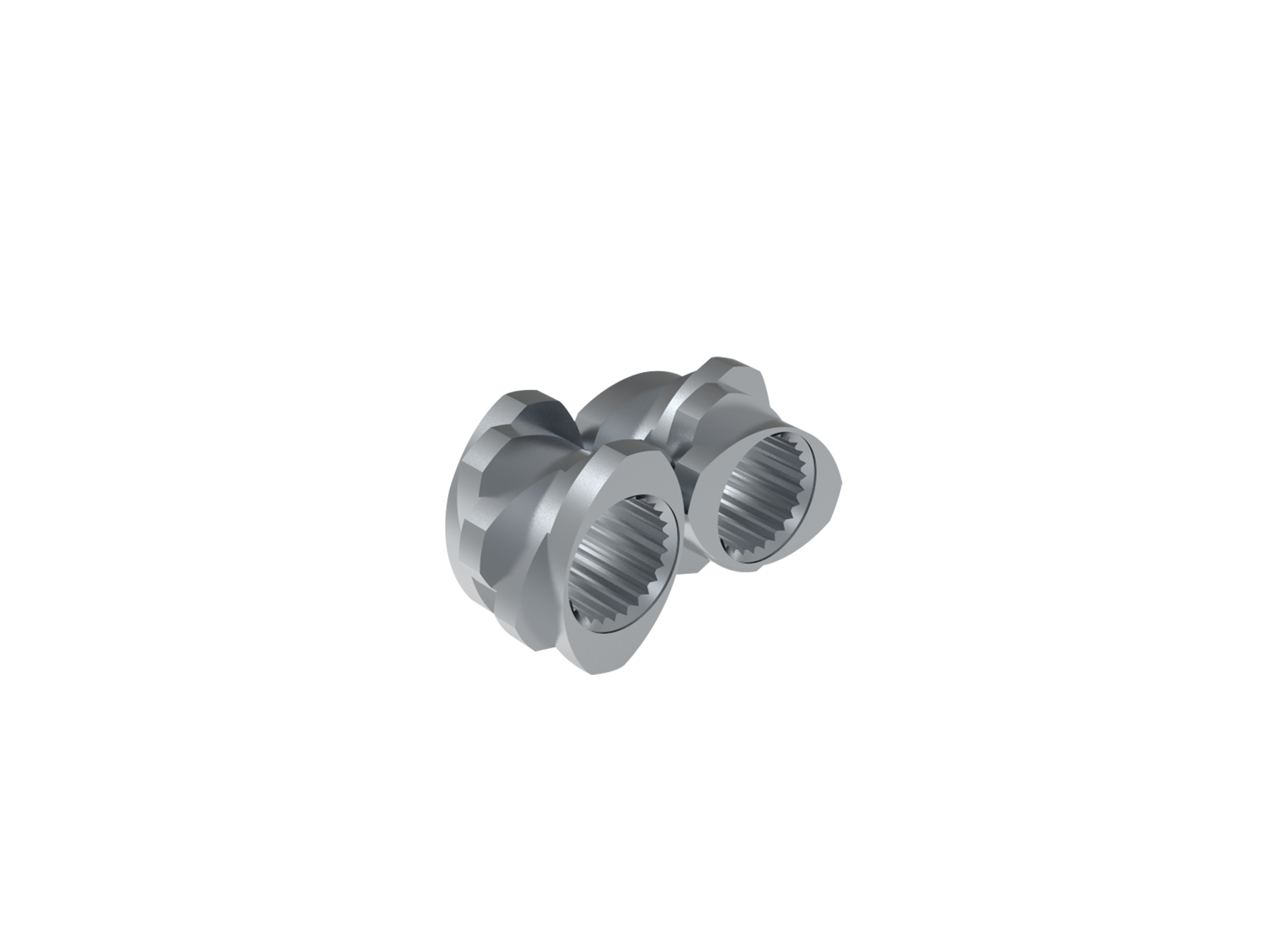

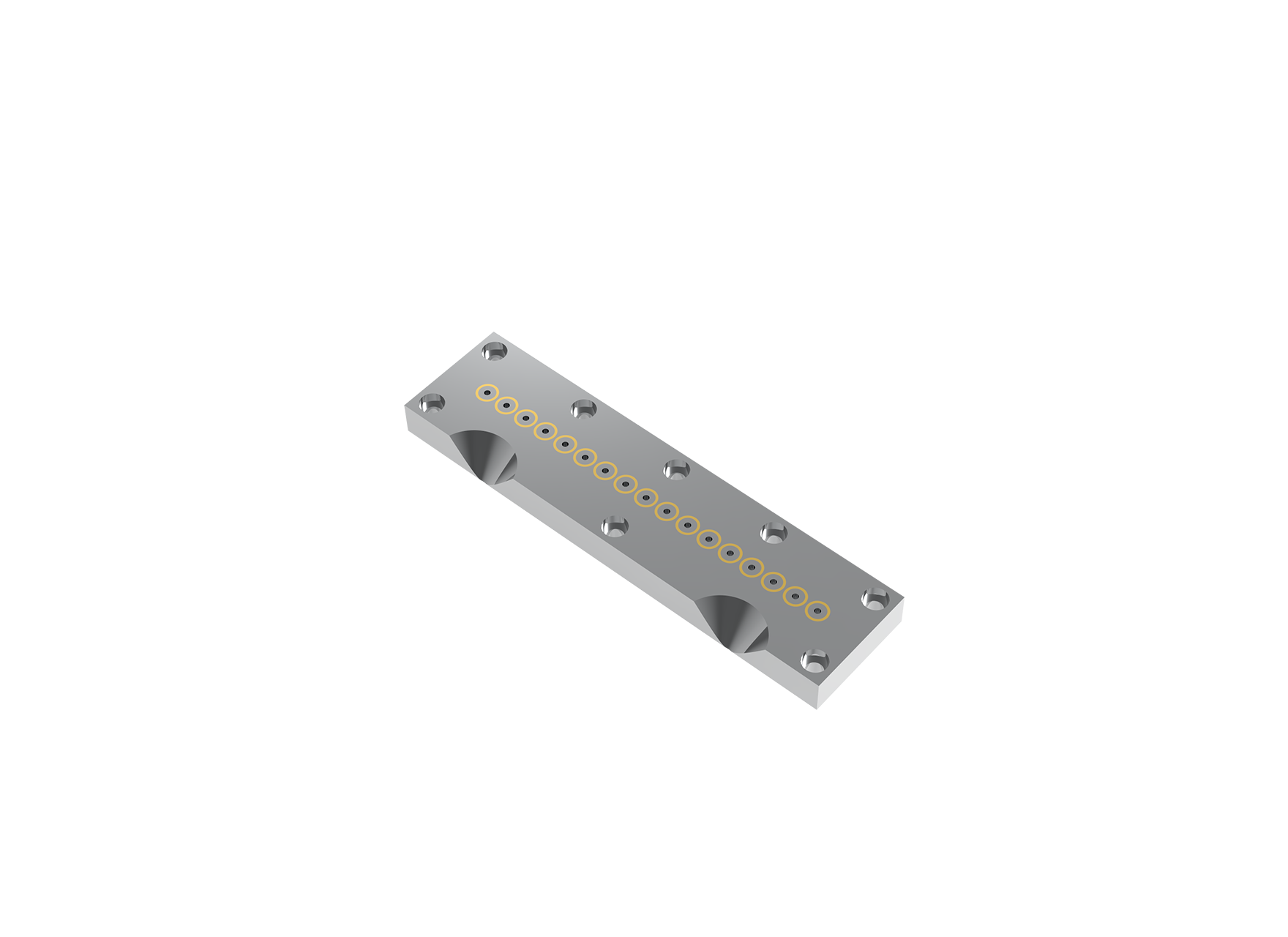

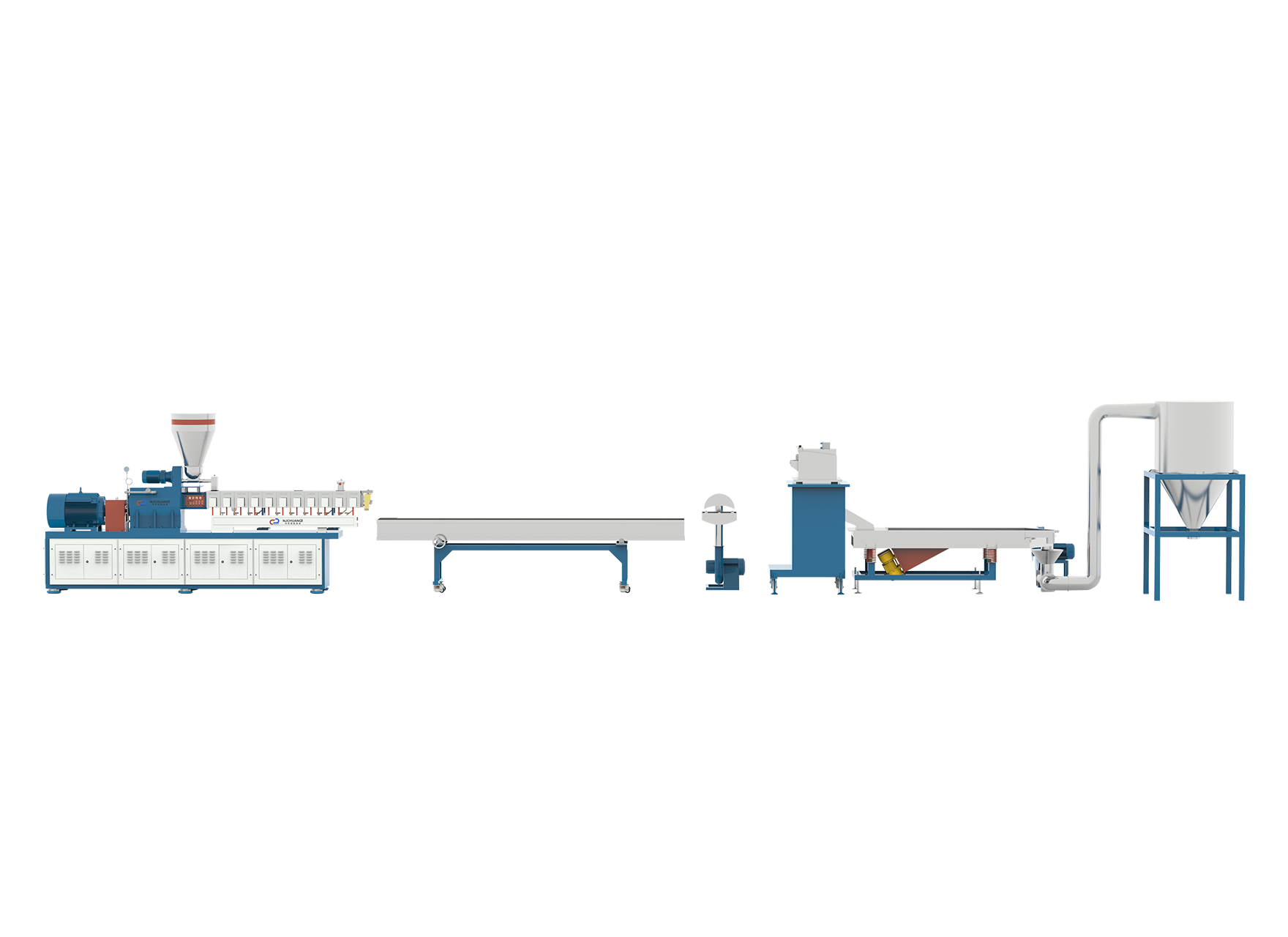

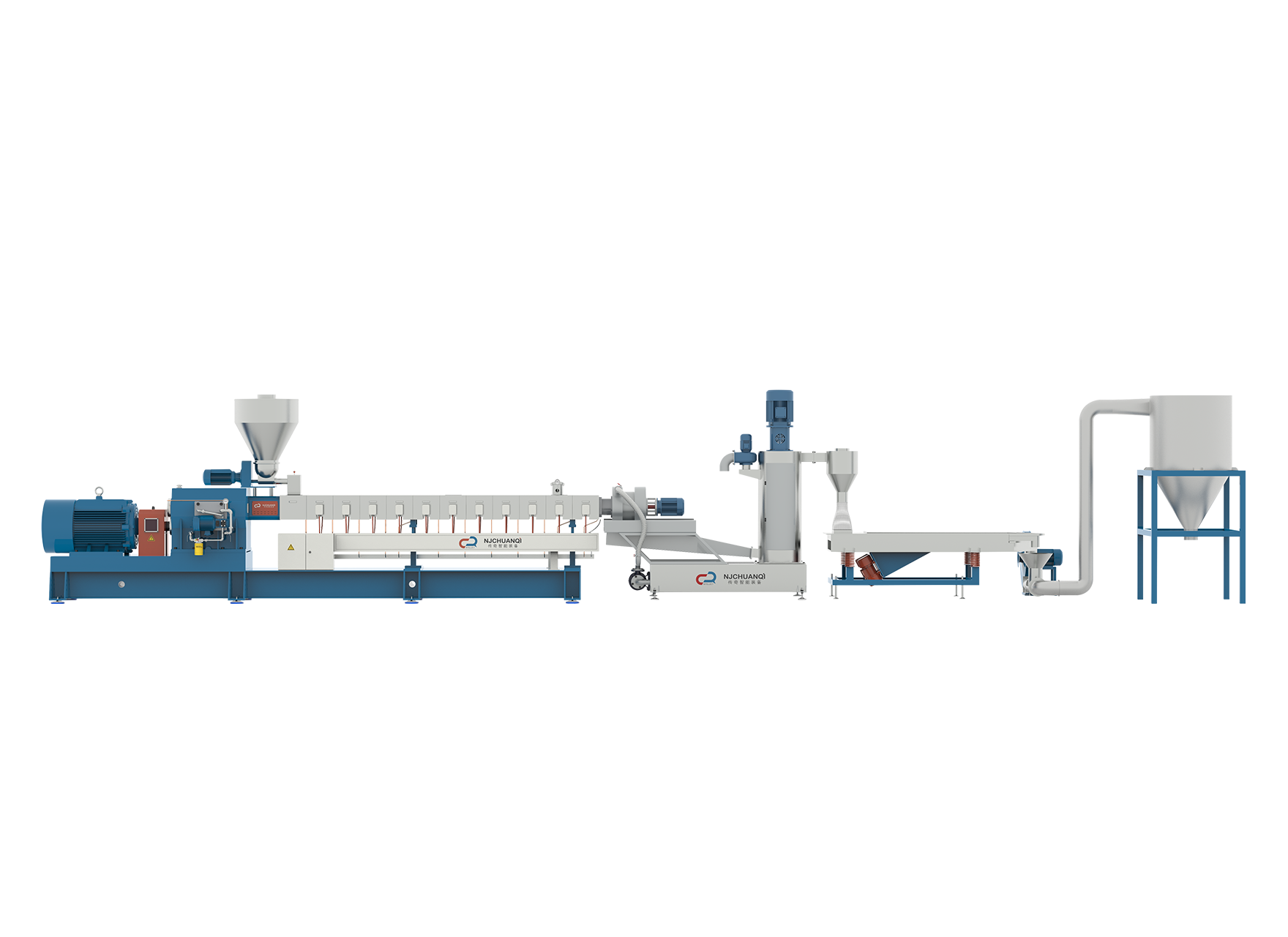

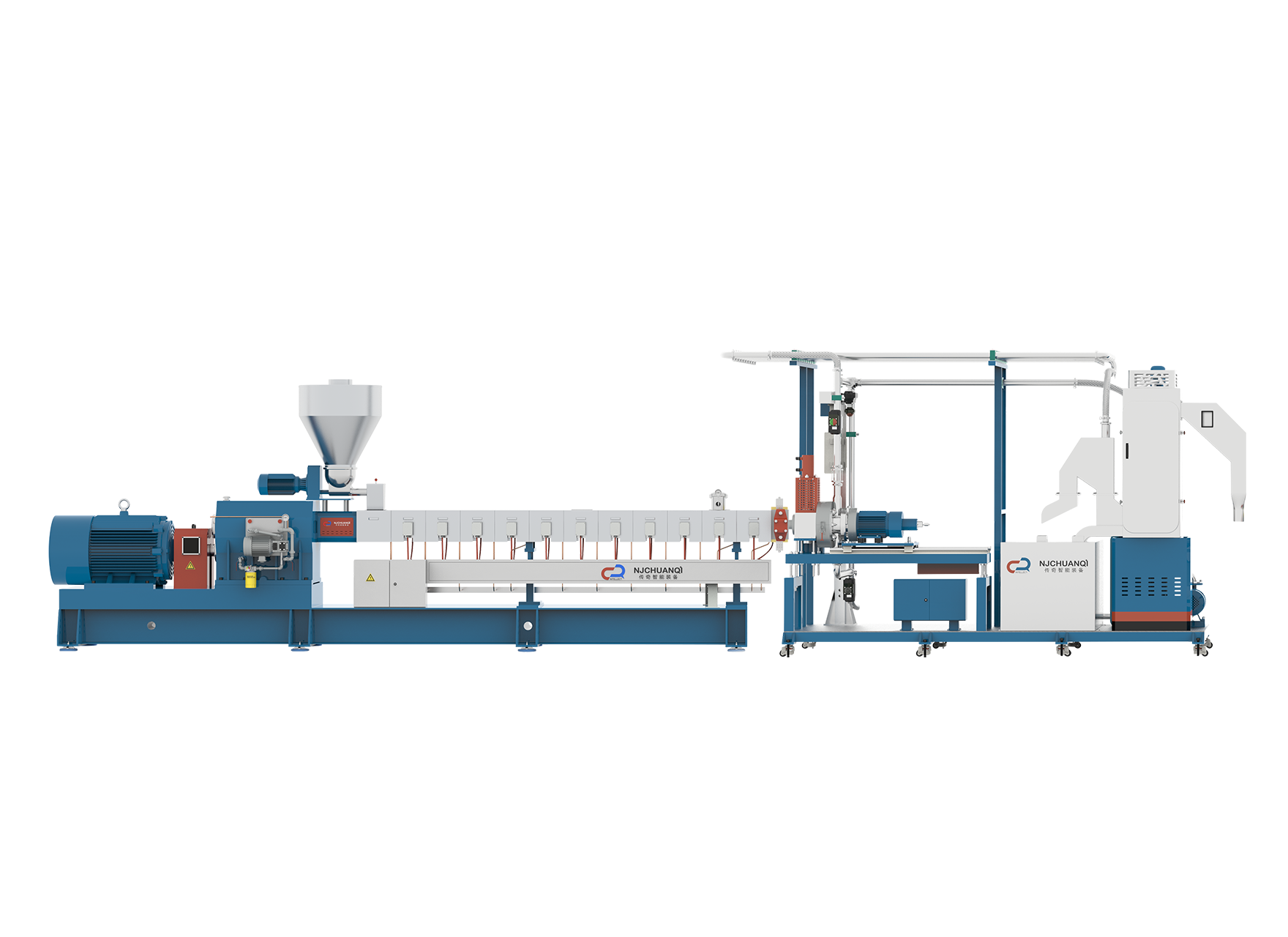

The Industrial Pelletizer Machine primarily functions by extruding raw materials through a die and cutting the extrudate into pellets using rotating knives. Uniformity in pellet size begins with a stable and consistent extrusion flow. This depends on the precise control of feed rates and extrusion pressure, ensuring that material passes evenly through the die openings.

The cutting mechanism is equally important. The speed of the rotating knives must be carefully synchronized with the extrusion rate. If the knives cut too fast or too slow relative to material flow, pellet length will vary, causing inconsistent sizes. Maintaining sharp and properly aligned knives prevents jagged cuts or irregular pellet shapes.

Temperature control within the machine also plays a significant role. Overheating may cause the pellets to deform after cutting, affecting their uniformity. Many machines incorporate cooling systems or temperature monitoring to keep processing conditions suitable, preserving pellet integrity.

The Role of Water Ring Pelletizers in Pellet Uniformity

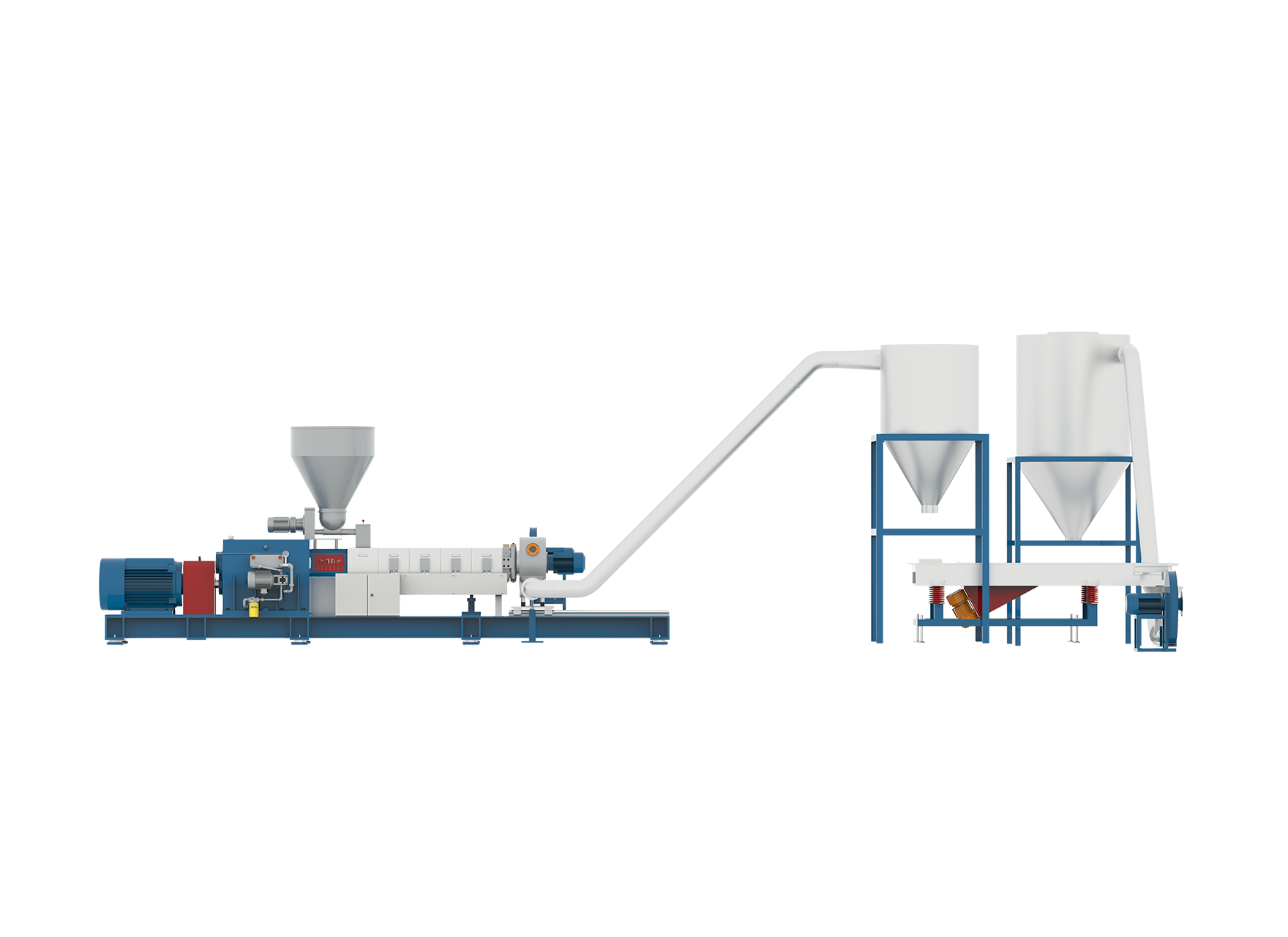

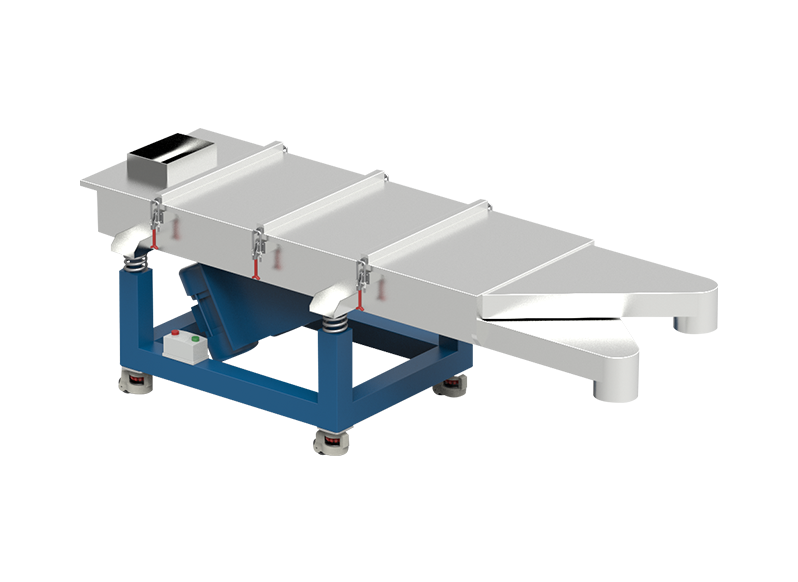

Water Ring Pelletizers take a different approach. In this system, molten material is extruded through a die directly into a water bath. A high-speed rotating water ring acts as the cutting tool, slicing the extruded strand into pellets. The immediate immersion in water rapidly cools and solidifies the pellets, preventing deformation and helping maintain uniform shape.

The synchronization between extrusion speed and water ring rotation is critical. Proper timing ensures that pellets are cut at consistent lengths. Additionally, the water flow rate and temperature must be controlled. If water is too warm or its flow is uneven, pellets can stick together or vary in size.

Because the water bath removes heat efficiently and provides a cushioning environment, pellets experience less stress and friction during cutting. This environment contributes to smooth, rounded pellet surfaces and consistent size.

Material Characteristics and Process Stability

Both types of pelletizers depend on the nature of the raw material. Materials with consistent viscosity and melting behavior facilitate more uniform extrusion and cutting. Variations in feedstock moisture or composition can cause fluctuations in pellet size, regardless of the pelletizing method.

Pre-treatment of raw materials, such as drying or homogenizing, improves feed consistency and reduces size variation. Maintaining a steady supply of material with stable properties is essential for achieving uniform pellets.

Maintenance and Calibration to Sustain Uniformity

Regular maintenance of pelletizing equipment ensures long-term pellet size consistency. For the Industrial Pelletizer Machine, routine inspection of dies, knives, and drive components is necessary to avoid wear that could cause irregular pellets.

In Water Ring Pelletizers, water quality and the condition of the rotating ring must be monitored to prevent clogging or imbalance. Calibration of speeds and synchronization settings should be performed regularly to maintain precise cutting action.

Operators often rely on feedback systems or visual inspections to adjust parameters dynamically, ensuring pellets meet size specifications throughout production

English

English 中文简体

中文简体 русский

русский عربى

عربى +86-189 1339 2785

+86-189 1339 2785